The Glazed Tile Roof Sheet Machine Factory Crafting Quality and Innovation

In today's construction industry, the importance of durable and aesthetically pleasing roofing materials cannot be overstated. Among the various options available, glazed tile roof sheets have gained significant popularity due to their appealing appearance and excellent weather resistance. The manufacturing of these roof sheets is a specialized process, primarily carried out in dedicated factories that house advanced machinery—known as glazed tile roof sheet machines.

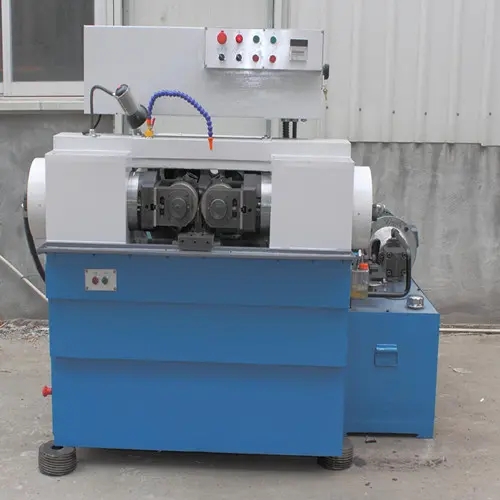

A glazed tile roof sheet machine factory is a hub of innovation, equipped with cutting-edge technology that streamlines the production process. These facilities are designed to transform raw materials such as steel coils into beautifully finished roof sheets that mimic the look of traditional ceramic tiles while offering improved performance and lower costs.

The manufacturing process begins with the selection of high-quality steel, which is then coated with a protective layer to enhance durability. The glazed tile roof sheet machine utilizes various manufacturing techniques, including roll forming and press forming, to shape the steel into desired profiles. During this phase, the machine applies a glaze coating that not only adds a glossy finish but also provides extra protection against corrosion, UV rays, and other environmental factors.

Automation plays a crucial role in the efficiency of a glazed tile roof sheet machine factory. Modern machines are programmed to execute precise cuts and folds, ensuring consistent product dimensions and quality. This level of automation reduces labor costs and minimizes human error, resulting in a product that meets stringent quality standards. Factories often implement stringent quality control measures throughout the production process, including regular inspections and testing, to ensure that every sheet meets the high expectations of customers.

Moreover, the factory environment is designed to optimize productivity. With well-organized workflows and strategically placed machinery, employees can work efficiently while maintaining a safe working environment. Many factories also prioritize sustainability by implementing eco-friendly practices, such as recycling scrap materials and reducing energy consumption during the manufacturing process.

The glazed tile roof sheet machine factory not only focuses on production but also emphasizes customer satisfaction. Each factory often has a dedicated research and development team that works tirelessly to innovate and improve product offerings. This team conducts market research to understand customer needs better and develop new designs and materials that cater to emerging trends in the roofing industry.

In conclusion, the glazed tile roof sheet machine factory represents a remarkable intersection of technology and craftsmanship. By producing high-quality roofing materials that combine beauty and functionality, these factories play an essential role in the construction landscape. As the demand for energy-efficient and aesthetically pleasing roofs continues to rise, the glazing tile roof sheet machine manufacturing sector is poised for further growth and innovation, ensuring that it meets the evolving needs of builders and homeowners alike.