The Evolution and Innovation of Glazed Tile Roof Sheet Machine Manufacturing

In the world of construction and architecture, roof materials play a pivotal role in not only the aesthetics of a building but also its durability and weather resistance. One of the most popular choices among builders and homeowners alike is the glazed tile roof. The appeal of glazed tiles lies in their beautiful finish, variety of colors, and ability to withstand harsh weather conditions. Behind this elegance and functionality lies a sophisticated manufacturing process, particularly in the production of glazed tile roof sheet machines, which has been evolving rapidly to meet contemporary demands.

The Importance of Glazed Tile Roofs

Glazed tiles have been used for centuries, prized for their waterproof qualities and their ability to reflect sunlight, thus keeping interiors cooler. With advancements in technology, modern glazed tile roofs are engineered to be even more sustainable and energy-efficient. They contribute to the aesthetic value of a structure while also providing significant insulation and durability. As construction practices evolve, so too does the need for efficient and high-quality machinery that can produce these essential roofing materials.

The Role of Glazed Tile Roof Sheet Machines

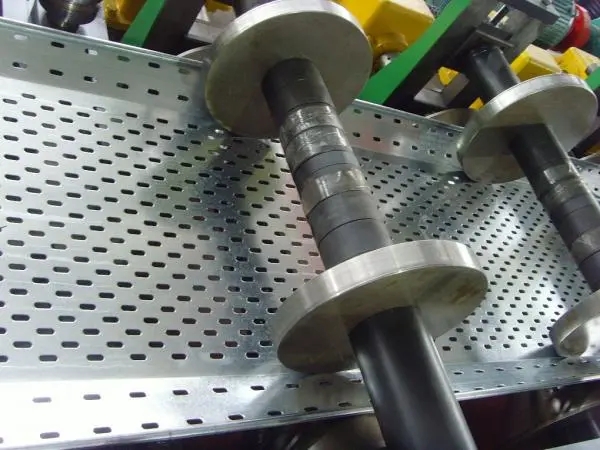

The glazed tile roof sheet machine is at the heart of tile manufacturing. This specialized machinery is designed to produce tiles that meet varied specifications and designs, ensuring that the final product is both functional and appealing. The machine typically consists of several components, including a forming machine, a cutting system, and a control panel.

1. Forming Process The forming machine takes raw materials, often a mixture of metals, plastics, and minerals, and shapes them into the desired tile form. Modern machines utilize advanced forming techniques, including hydraulic systems, to ensure precision and consistent quality in every tile produced.

2. Cutting System After the tiles are formed, they need to be cut to exact dimensions. This is where high-precision cutting systems come into play. These systems use laser or high-efficiency blades to ensure that each tile will fit seamlessly onto the roof structure.

3. Control Panels and Automation Today’s glazed tile roof sheet machines are often programmable and equipped with sophisticated control panels that allow operators to adjust settings for different tile designs and specifications. Automation has become a key feature, enabling continuous production with minimal manual intervention. This not only speeds up the manufacturing process but also helps maintain high standards of quality control.

Innovations in Producing Glazed Tile Roof Sheet Machines

Recent years have seen significant innovations in the design and capability of glazed tile roof sheet machines. With advancements in technology, manufacturers are focusing on improving efficiency, reducing energy consumption, and enhancing the overall quality of the tiles produced.

1. Energy Efficiency New machines are designed to consume less power while maintaining high output levels. This not only reduces operational costs but also contributes to the sustainability of the production process.

2. Materials and Coatings The use of advanced materials for components and cutting-edge coatings for the machines ensures longevity and resistance to wear and tear. This translates to longer machine life and reduced maintenance costs for manufacturers.

3. Customization With the growing demand for personalized designs, modern machines offer customization options that allow manufacturers to create unique tiles tailored to individual customer needs. This trend towards customization is reshaping the market, as builders seek distinctive roofing solutions.

Conclusion

The glazed tile roof sheet machine is more than just a piece of equipment; it represents the intersection of artistry and engineering. As the demand for high-quality, aesthetically pleasing, and durable roofing materials increases, manufacturers must continue to innovate. By embracing new technologies and refining production processes, the industry can not only meet contemporary construction needs but also pave the way for a more sustainable future. The evolution of glazed tile roof sheet machines is a testament to the resilience and creativity of the manufacturing sector, ensuring that we continue to enjoy the benefits of beautiful and functional roof designs for generations to come.