The Glazed Tile Roof Sheet Machine Factory Revolutionizing Roofing Solutions

In recent years, the construction industry has seen a significant shift towards the use of innovative materials and processes, primarily driven by the demand for cost-effective, durable, and aesthetically pleasing roofing solutions. One standout product in this evolution is the glazed tile roof sheet, which has become increasingly popular among architects, builders, and homeowners alike. At the heart of this transformation lies the glazed tile roof sheet machine factory, an establishment that plays a vital role in the manufacturing of these unique roofing sheets.

Understanding Glazed Tile Roof Sheets

Glazed tile roof sheets are designed to mimic the traditional clay or ceramic tiles, offering the same aesthetic appeal while being more lightweight and easier to install. These sheets are typically made from metal or other durable materials, providing exceptional resistance to weather elements, corrosion, and impacts. The glossy finish of these glazed sheets not only enhances their visual attractiveness but also provides additional benefits, such as lower maintenance and improved energy efficiency.

The Role of the Manufacturing Process

The glazed tile roof sheet machine factory specializes in producing these advanced roofing materials through a highly sophisticated process. This begins with the selection of quality raw materials, which are essential for ensuring durability and longevity of the final products. Advanced machinery and technology are utilized to extrude and shape the roof sheets, followed by stringent quality control measures to ensure each sheet meets the required standards.

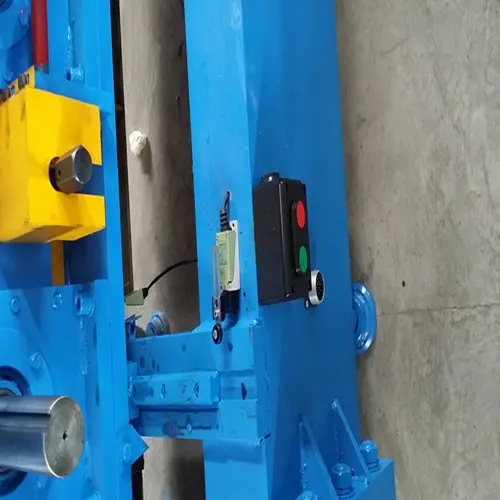

The manufacturing process typically involves several key stages

1. Raw Material Preparation High-quality steel or other suitable metal is acquired and prepared for processing. 2. Forming The prepared materials are fed into pressing machines, which shape them into the desired tile profiles. This is a critical stage where precision and consistency are paramount. 3. Coating and Glazing After forming, the sheets undergo a glazing process. A special coating is applied to enhance appearance and protect against corrosion and UV degradation. This not only contributes to the aesthetic appeal but also enhances the overall lifespan of the roofing materials. 4. Cutting and Packaging Once the glazing is complete, the sheets are cut to specified lengths and packaged for delivery to clients worldwide.

Benefits of Glazed Tile Roof Sheet Machines

The machines used in these factories are built for efficiency and productivity. They reduce waste and lower energy consumption, making the manufacturing process more sustainable and cost-effective. These machines also enable manufacturers to produce a variety of styles and colors, allowing for customizable roofing solutions to meet diverse customer needs. This flexibility is a competitive advantage in a market where individuality and personalization are increasingly sought after by consumers.

Environmental Considerations

An emerging trend in the construction industry is a focus on environmentally friendly practices. Glazed tile roof sheet factories are adapting to this trend by incorporating eco-friendly techniques in their manufacturing processes. For example, recycling scrap materials and using coatings that are less harmful to the environment are practices that many factories are adopting.

Conclusion

As the demand for durable and visually appealing roofing alternatives rises, the glazed tile roof sheet machine factory stands at the forefront of this industry shift. With a commitment to quality, innovation, and sustainability, these factories not only revolutionize roofing solutions but also contribute to creating a more energy-efficient and beautiful built environment. With advancements in technology and manufacturing processes, the future of glazed tile roofing is promising, ensuring that homeowners and builders alike have access to superior roofing materials that combine both form and function.