Exploring the Glazed Tile Roof Sheet Machine Factory Innovations in Roofing Solutions

In recent years, the construction industry has witnessed significant advancements in roofing materials and technologies. Among these innovations, the glazed tile roof sheet has gained immense popularity for its aesthetic appeal and durability. This surge in demand has led to the establishment of specialized factories focused on producing high-quality glazed tile roof sheets using advanced machinery. In this article, we will explore the processes and technologies involved in a typical glazed tile roof sheet machine factory.

At the heart of the glazed tile roof sheet production process is a sophisticated machine capable of transforming raw materials into finished roofing sheets. The factory typically employs an automated production line, which ensures efficiency and consistency in the manufacturing process. The primary materials used in the production of glazed tile roof sheets are metal substrates, often made from steel or aluminum, which provide strength and resilience.

The first step in the manufacturing process is the preparation of the metal substrate. This involves cleaning, coating, and pre-processing the metal to enhance its adhesion properties and protect it from corrosion. Following this, the substrate is fed into the roll forming machine, where it undergoes a series of bends and shapes to create the desired tile profile. This stage is crucial as it determines the final appearance and structural integrity of the roof sheets.

Once the sheets have been shaped, they undergo a glazing process that not only adds to their aesthetic appeal but also provides an extra layer of protection. The glazing involves the application of a specially formulated coating that enhances durability while giving the sheets a glossy finish. This step is particularly important as it protects the roofing material from UV rays, extreme weather conditions, and other environmental factors.

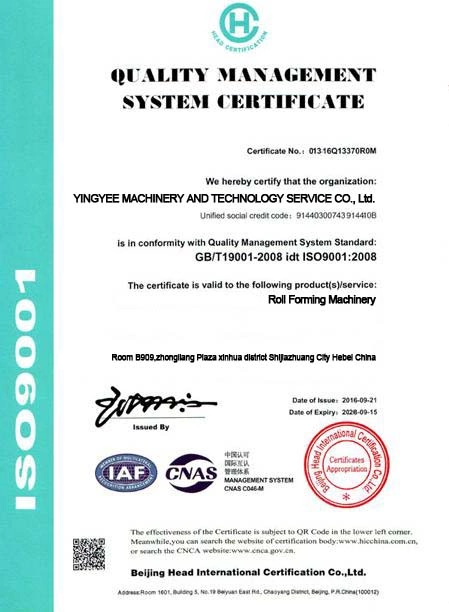

Quality control is a cornerstone of any reputable glazed tile roof sheet machine factory. Throughout the production process, constant monitoring and testing are conducted to ensure that the sheets meet industry standards and customer specifications. This includes checks for dimensional accuracy, coating thickness, and overall finish. Only products that pass these stringent quality tests are approved for shipment.

In addition to the manufacturing process, modern glazed tile roof sheet factories often leverage technology for better efficiency and sustainability. Many factories now utilize energy-efficient machinery and techniques that reduce waste and energy consumption throughout the production cycle. Advanced data management systems allow for seamless tracking of materials and inventory, ensuring timely deliveries and minimizing production delays.

The benefits of glazed tile roof sheets extend beyond their production. These roofing materials offer superior insulation, reducing energy costs for homeowners and commercial buildings alike. Their lightweight nature eases installation processes, and their aesthetic versatility allows for a wide range of architectural designs, making them a preferred choice in contemporary construction.

In conclusion, the glazed tile roof sheet machine factory exemplifies the intersection of technology and craftsmanship in the modern manufacturing industry. With a focus on quality, efficiency, and sustainability, these factories are poised to meet the growing demand for durable and aesthetically pleasing roofing solutions. As the construction sector continues to evolve, innovations in glazed tile roof sheet production will undoubtedly play a crucial role in shaping the future of roofing materials.