The Evolution of Galvanizing Pipe Making Machines

Galvanizing pipe making machines play a crucial role in the manufacturing process of steel pipes, particularly those used in construction, plumbing, and various industrial applications. As technology has advanced, these machines have evolved significantly, enhancing efficiency, quality, and environmental sustainability in the production of galvanized pipes.

Understanding Galvanization

Galvanization is the process of applying a protective zinc coating to iron or steel to prevent rusting. This process is essential for extending the lifespan of pipes, especially in harsh environments where exposure to moisture and corrosive substances is common. The galvanizing process typically involves hot-dip galvanization, where pipes are submerged in molten zinc, creating a robust barrier against corrosion.

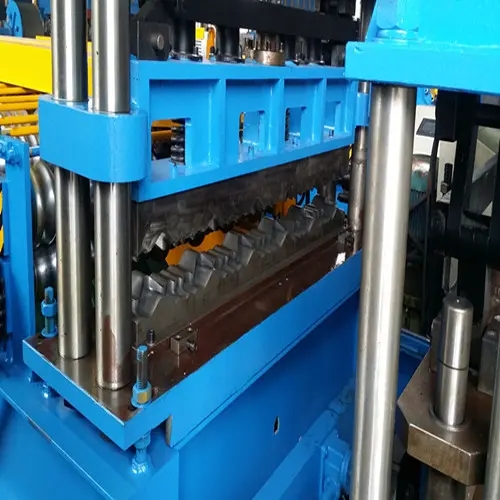

The Role of Pipe Making Machines

The pipe making machine is central to the production of high-quality galvanized pipes. These machines are designed to automate the process of cutting, forming, welding, and galvanizing steel strips into pipes. Modern galvanizing pipe making machines integrate advanced technologies such as Computer Numerical Control (CNC), which ensures precision in the manufacturing process, resulting in uniform pipe dimensions and improved structural integrity.

Technological Advancements

Recent developments in galvanizing pipe making machines have led to the incorporation of energy-efficient systems and automation. These innovations not only reduce operational costs but also minimize waste and emissions, addressing environmental concerns associated with industrial manufacturing. Smart sensors and real-time monitoring systems enable operators to track various parameters, optimizing production and ensuring consistent quality.

Additionally, the adoption of robotics in the pipe making process has transformed traditional manufacturing practices. Robots can perform repetitive tasks such as welding and coating with enhanced speed and accuracy, reducing human error and improving safety in the workplace.

Quality Assurance

Quality is paramount in the production of galvanized pipes, as they must meet stringent industry standards to ensure safety and reliability. Modern machines are equipped with advanced testing and inspection technologies that assess the physical and chemical properties of the pipes throughout the production process. Automated data collection and analysis provide manufacturers with insights into performance, facilitating continuous improvement.

Global Market Trends

The global demand for galvanized pipes continues to rise, driven by urbanization and infrastructure development. As countries invest in modernization and sustainable construction methods, the need for durable and corrosion-resistant materials like galvanized pipes grows. Manufacturers that invest in state-of-the-art pipe making machines will be better positioned to meet this demand, maintain competitive advantages, and improve profitability.

Conclusion

In conclusion, galvanizing pipe making machines are essential for producing high-quality, durable pipes that meet the needs of various industries. With ongoing technological advancements, these machines are becoming more efficient, environmentally friendly, and capable of producing pipes that can withstand the test of time. As the world continues to evolve, so will the methods and machines used to create the infrastructure that supports our modern society.