The Evolution and Benefits of Galvanized Metal C/Z Purlin Roll Forming Machines

In modern construction and building design, material efficiency and structural integrity are paramount. Among the various materials used, galvanized metal has emerged as a favorite due to its durability and resistance to corrosion. One of the most efficient ways to fabricate galvanized metal components for construction is through the use of C/Z purlin roll forming machines.

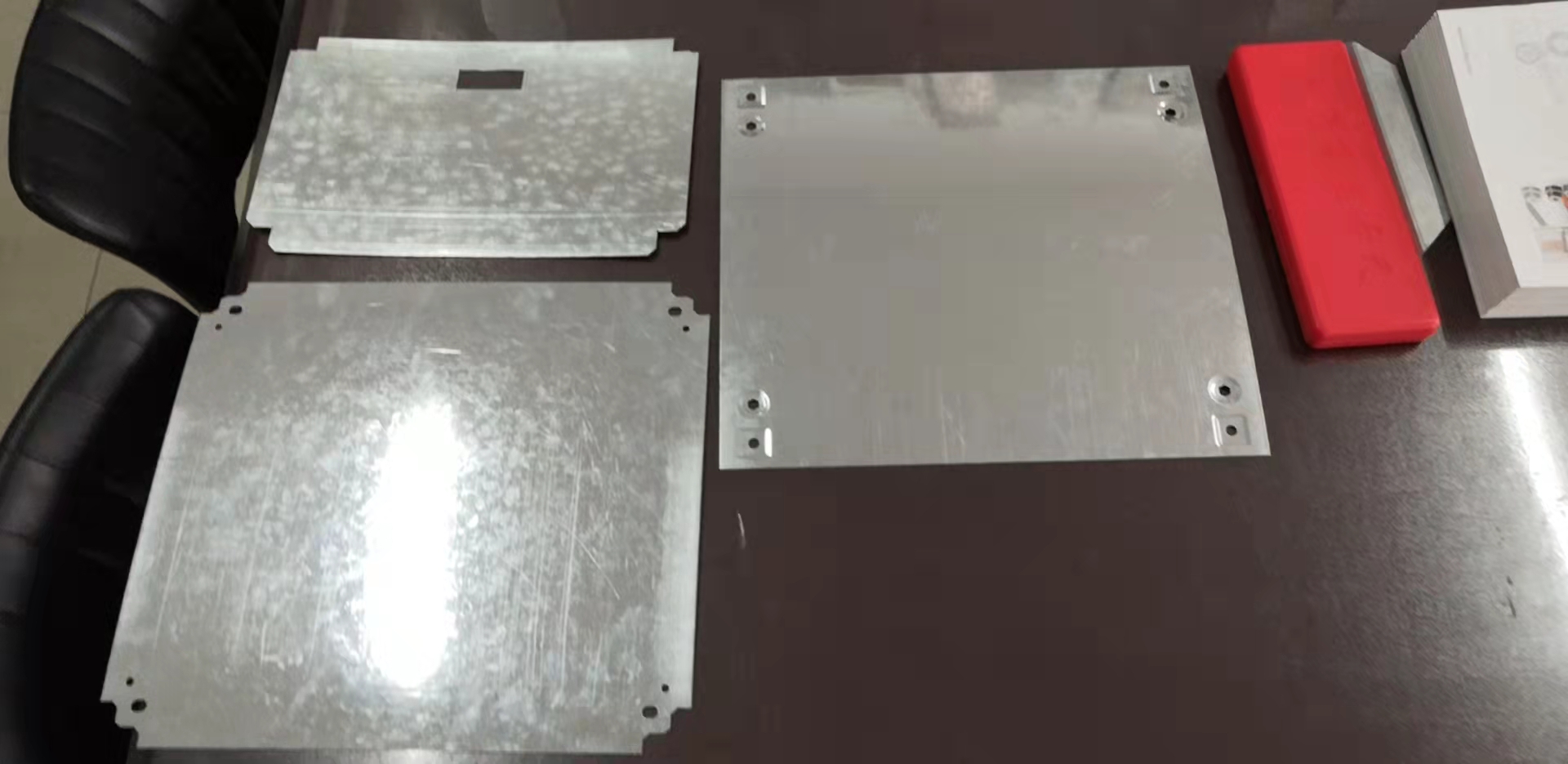

Understanding C/Z Purlins

C/Z purlins are structural components widely used in steel construction. They are often found in roofs, walls, and various frameworks due to their high strength-to-weight ratio and versatility. The “C” and “Z” shapes refer to the cross-sectional profiles of the purlins. C purlins typically support roof structures while Z purlins are used for wall applications.

The advantages of using these profiles are numerous, including reduced material waste, savings in transportation costs due to lighter weight, and the ability to produce custom lengths on-site. Moreover, the hot-dip galvanization process enhances the longevity of these purlins, protecting them against environmental factors and extending their lifespan.

The Role of Roll Forming Machines

Roll forming is a process utilized to convert flat strips of metal into specific shapes that can be used in construction. The roll forming machines used for producing C/Z purlins operate by feeding a continuous coil of galvanized steel through a series of rollers that gradually shape the metal into the desired profile.

These machines are designed for both efficiency and precision. As the metal passes through, the rollers progressively bend the material into the required shapes with minimal tolerance for error. This level of precision is vital in ensuring that each purlin fits perfectly into the overall structure, improving the building's stability and integrity.

Advantages of Galvanized C/Z Purlin Roll Forming Machines

1. Customization One of the most significant benefits of using a roll forming machine is the ability to customize purlin dimensions. Builders can produce various lengths and thicknesses based on project needs, allowing for greater flexibility and adaptability in construction design.

2. High Efficiency Roll forming machines are capable of producing large volumes of purlins in a short amount of time. This high-speed production reduces labor costs and leads to faster construction timelines, which is crucial in competitive markets.

3. Reduced Material Waste The precision of roll forming minimizes scrap metal and waste, making it an environmentally friendly option. Additionally, because galvanized steel is used, the durability of the final product reduces the need for frequent replacements, contributing to sustainability.

4. Enhanced Durability Galvanization provides a protective barrier against corrosion, making Galvanized C/Z purlins ideal for use in various environments. Whether in coastal regions with salty air or in industrial areas, these purlins maintain their integrity over time, reducing maintenance costs.

5. Cost-Effectiveness While the initial investment in a roll forming machine may be substantial, the long-term savings are significant. Lower material costs due to reduced waste, decreased labor expenses, and minimized maintenance needs all contribute to a more cost-effective solution for builders and contractors.

Conclusion Embracing the Future of Construction

The advancements in galvanized metal C/Z purlin roll forming technology signify a transformation in construction practices. By integrating these machines into projects, builders can capitalize on the benefits of precision, efficiency, and sustainability. As construction continues to evolve with new technologies and materials, the role of galvanized C/Z purlin roll forming machines will undoubtedly grow, providing strength and reliability to modern architectural endeavors.

Thus, as we look forward to the future of construction, embracing these innovations will lead not only to structural advancements but also to a more sustainable and economically viable industry.