Understanding Galvanized Deck Floor Roll Forming Machines

In the realm of construction and manufacturing, the demand for efficient and durable building materials has led to significant advancements in technology. One such innovation is the galvanized deck floor roll forming machine, a pivotal tool in producing high-quality metal decking used in various structures, including commercial buildings, warehouses, and parking garages. This article explores the features, functionalities, and benefits of these machines, underscoring their importance in modern construction.

What is a Galvanized Deck Floor Roll Forming Machine?

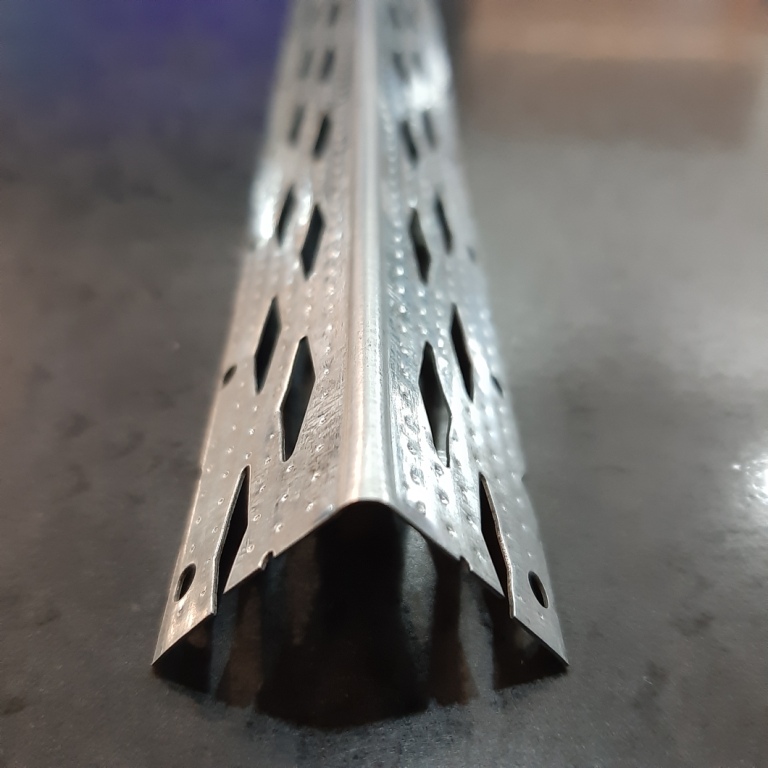

A galvanized deck floor roll forming machine is specifically designed to produce metal decking sheets from galvanized steel coils. The process begins with feeding the steel coil into the machine, which then shapes it into the desired profile through a series of rollers. The machine utilizes precision engineering to ensure consistent thickness and dimensional accuracy, making it a vital asset for construction projects needing reliable flooring solutions.

The Benefits of Galvanized Steel

Galvanized steel, which undergoes a coating process to prevent rust and corrosion, is favored in construction for several reasons

1. Durability Galvanized steel structures are long-lasting and can withstand harsh weather conditions, making them ideal for outdoor and industrial applications.

2. Low Maintenance The protective zinc coating significantly reduces maintenance costs over time, as it prevents the common issues associated with unprotected steel, such as rust and degradation.

Key Features of the Machines

Modern roll forming machines come equipped with advanced features that enhance their efficiency and productivity

- Automation Many machines are fully automated, allowing for precise control over the forming process. This automation minimizes human error and increases production speed.

- Versatility These machines can produce various deck profiles, accommodating different project requirements and architectural designs.

- User-Friendly Interface Most roll forming machines feature intuitive control panels that enable operators to set parameters easily, monitor the process, and make real-time adjustments.

- High Production Rate Advanced machines can produce large quantities of decking sheets in a short time, meeting the demands of large-scale construction projects.

Applications in Construction

The versatility of galvanized deck floor roll forming machines makes them suitable for various applications. They are commonly used to create floor decking for commercial buildings, residential complexes, and industrial warehouses. These decking sheets provide structural support and can also serve as a base for concrete slabs, enhancing the overall integrity and safety of the building. Additionally, galvanized decking is increasingly being used in roof systems, offering a lightweight yet robust solution.

Conclusion

In conclusion, the galvanized deck floor roll forming machine plays a vital role in the construction industry by enabling the efficient production of durable and cost-effective metal decking solutions. As construction practices continue to evolve and the demand for high-quality materials increases, these machines are likely to become even more essential in various applications. Investing in a reliable roll forming machine not only streamlines production processes but also enhances the quality of the final product, ultimately contributing to the success of modern construction projects. As we move forward, embracing innovations in manufacturing will be key to meeting the evolving demands of the industry while ensuring sustainability and efficiency.