The Importance of Galvanized Cable Tray Making Machines

In today's rapidly advancing technological landscape, the distribution and management of electrical wiring and cables are crucial for ensuring efficient operation in various industries. A fundamental component in these systems is the cable tray, which provides support and organization for electrical cables. Among the various types of cable trays available, galvanized cable trays stand out for their durability and corrosion resistance. This article explores the significance of galvanized cable tray making machines in manufacturing these essential products.

Galvanized cable trays are made from steel that has been coated with a layer of zinc to protect against rust and corrosion. This protective coating increases the lifespan of the trays, making them ideal for both indoor and outdoor applications, including industrial plants, commercial buildings, and infrastructure projects. The ability to withstand harsh environments and moisture makes galvanized cable trays an ideal choice for any electrical installation.

To meet the rising demand for galvanized cable trays, manufacturers rely on specialized machines designed to produce these trays efficiently and effectively

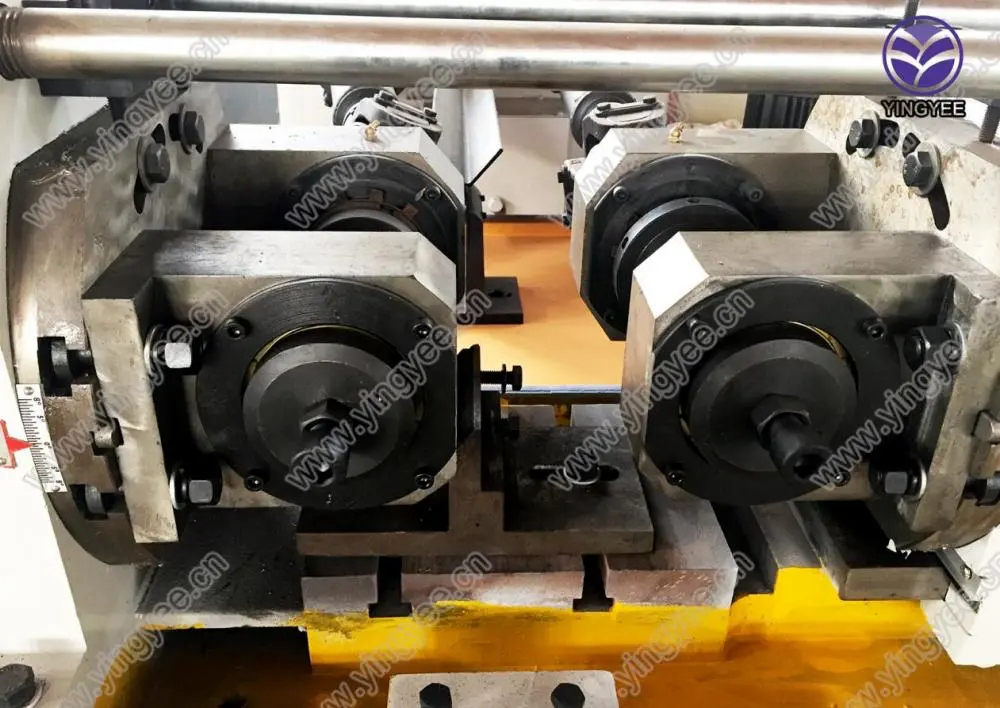

. The galvanized cable tray making machine streamlines the entire manufacturing process, from the initial fabrication of the steel to the final coating in zinc. This machine is equipped with advanced technology that enhances production speed and accuracy, allowing manufacturers to cater to high-volume orders without compromising quality.These machines typically consist of several components, including a decoiler, forming unit, cutting device, and galvanizing unit. The decoiler unwinds the steel coil, which then passes through the forming unit where it is shaped into the desired tray profile. After forming, the trays are cut to length before being sent through the galvanizing process. This automated approach minimizes manual labor, reduces production time, and ensures consistency in product quality.

Moreover, the use of galvanized cable tray making machines contributes to cost-effectiveness for manufacturers. By optimizing the production process, these machines reduce material waste and energy consumption. This efficiency not only lowers operational costs but also aligns with environmental sustainability goals by minimizing the ecological footprint of production activities.

In addition to efficiency and cost savings, these machines offer versatility. They can be adjusted to produce various tray sizes and designs, accommodating the diverse needs of clients across different sectors. This adaptability is crucial in a market where customization and flexibility are increasingly demanded.

Furthermore, the reliability of galvanized cable trays made with advanced manufacturing machines enhances the safety of electrical installations. Properly manufactured trays provide secure and organized cable management, reducing the risk of electrical hazards and ensuring compliance with safety standards.

In conclusion, galvanized cable tray making machines are indispensable in modern manufacturing processes. They not only facilitate the production of robust and high-quality cable trays but also contribute to operational efficiency, cost savings, and safety in electrical installations. As industries continue to evolve, the importance of these specialized machines will only grow, ensuring that the infrastructure supporting our technological advancements remains strong and reliable.