Galvanized Metal C/Z Purlin Roll Forming Machine Revolutionizing Construction and Steel Fabrication

In the modern construction and manufacturing industries, the demand for high-quality, durable structural components has never been more pressing. Among these components, C and Z purlins play a crucial role in supporting roofs, walls, and other structures. The galvanized metal C/Z purlin roll forming machine has emerged as a game-changing technology, streamlining the production of these essential components while ensuring longevity and resilience.

Understanding C and Z Purlins

C and Z purlins are steel sections used extensively in roofing and framing applications. Their unique shapes provide excellent support and are designed to withstand various loads, making them ideal for both light and heavy constructions. Galvanization, the process of applying a protective zinc coating, enhances the corrosion resistance of these steel sections, increasing their lifespan and maintaining structural integrity in diverse environments.

The Role of Roll Forming Machines

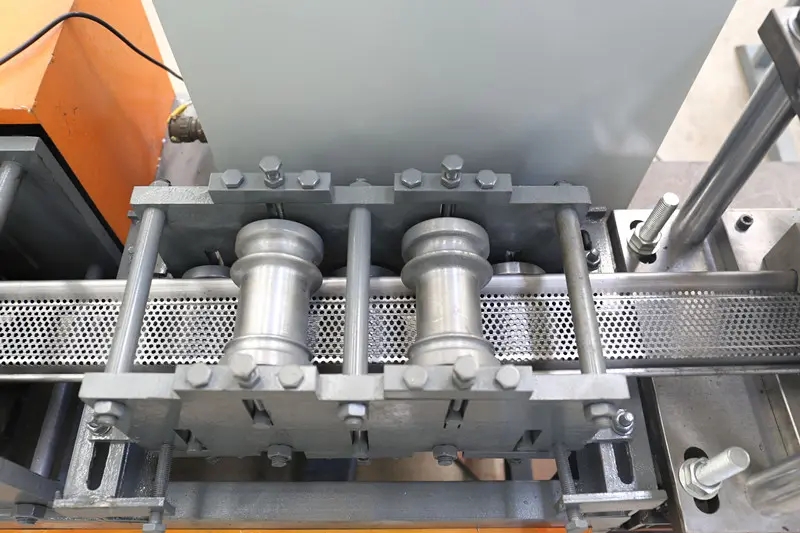

The roll forming process involves feeding a continuous strip of metal through a series of rollers. These rollers gradually shape the metal into the desired purlin profiles (C or Z shapes), offering precision and consistency. The galvanized metal C/Z purlin roll forming machine is designed to efficiently produce these components with minimal waste and high speed, which is vital in meeting the increasing demands in the construction sector.

Benefits of Galvanized Metal C/Z Purlin Roll Forming Machines

1. High Efficiency These machines are engineered for high throughput, meaning they can produce large quantities of purlins in a shorter amount of time. This efficiency is crucial for construction projects that are time-sensitive.

2. Customization Many roll forming machines offer flexibility in design, allowing manufacturers to customize purlin dimensions and shapes according to specific project requirements. This adaptability ensures that clients receive tailored solutions that fit their unique needs.

3. Quality Control The automated nature of roll forming minimizes human error, ensuring consistent quality throughout the production process. Additionally, the use of galvanized steel ensures that the finished products are resistant to rust and corrosion, thus enhancing their durability.

4. Cost-Effectiveness By optimizing material use and reducing waste, galvanized metal C/Z purlin roll forming machines contribute to lower production costs. Furthermore, the longevity of galvanized products translates into lower maintenance costs for end-users.

5. Environmental Impact The use of galvanized steel is also an environmentally friendly option. Steel is recyclable, and the roll forming process maximizes the use of raw materials, aligning with sustainable manufacturing practices.

Applications in Various Industries

The versatility of C and Z purlins produced by these machines makes them suitable for a wide range of applications. They are commonly used in commercial buildings, industrial facilities, agricultural structures, and residential projects. Whether it’s for a warehouse, a shopping center, or a farm shed, the robustness and reliability of galvanized purlins provide structural integrity and support.

Conclusion

The galvanized metal C/Z purlin roll forming machine is a pivotal development in the construction and manufacturing industries. By combining efficiency, customization, and durability, it enables manufacturers to meet the demands of modern construction with ease. As the construction landscape continues to evolve, investing in such advanced technologies will undoubtedly lead to better quality structures, sustainable practices, and optimized production processes. With these machines, the future of construction is not only bright but also more robust and efficient.