Delving into the world of metal and construction industries reveals the essential role of machinery like the furring channel roll forming machine. This advanced equipment is vital for shaping metal channels used in interior systems, supporting suspended ceilings, or lining walls. With years of experience and deep expertise in metal forming solutions, our journey with the furring channel roll forming machine is a testament to the transformative power and precision of this technology.

The efficiency and precision of a furring channel roll forming machine cannot be overstated. It is meticulously designed to produce furring channels with exact specifications and unparalleled consistency. These machines are capable of handling high-strength steels and other metals with ease, ensuring that every channel produced meets stringent industry standards. Their performance embodies the pinnacle of engineering sophistication, offering highly repeatable processes that significantly decrease human error and material wastage.

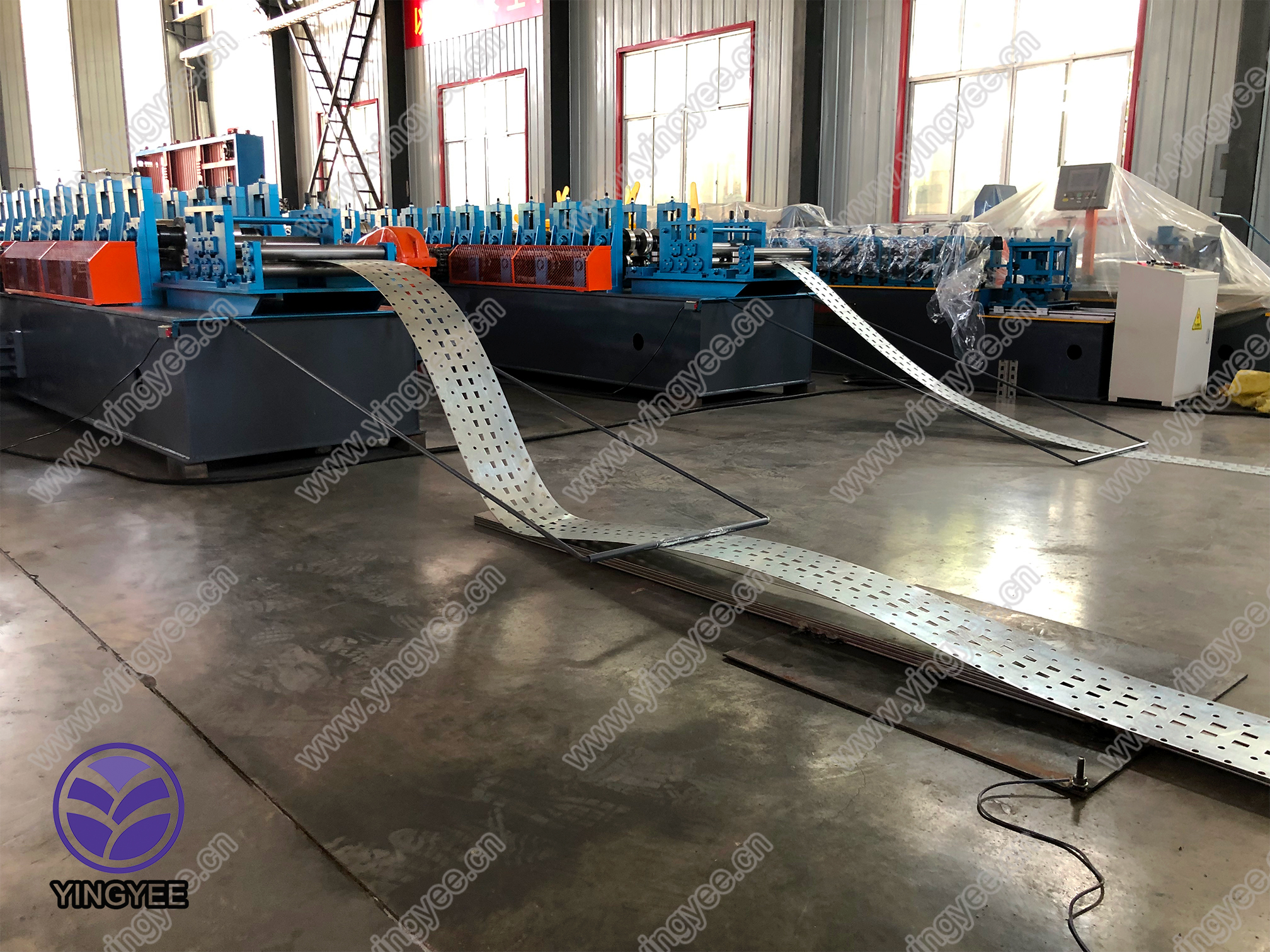

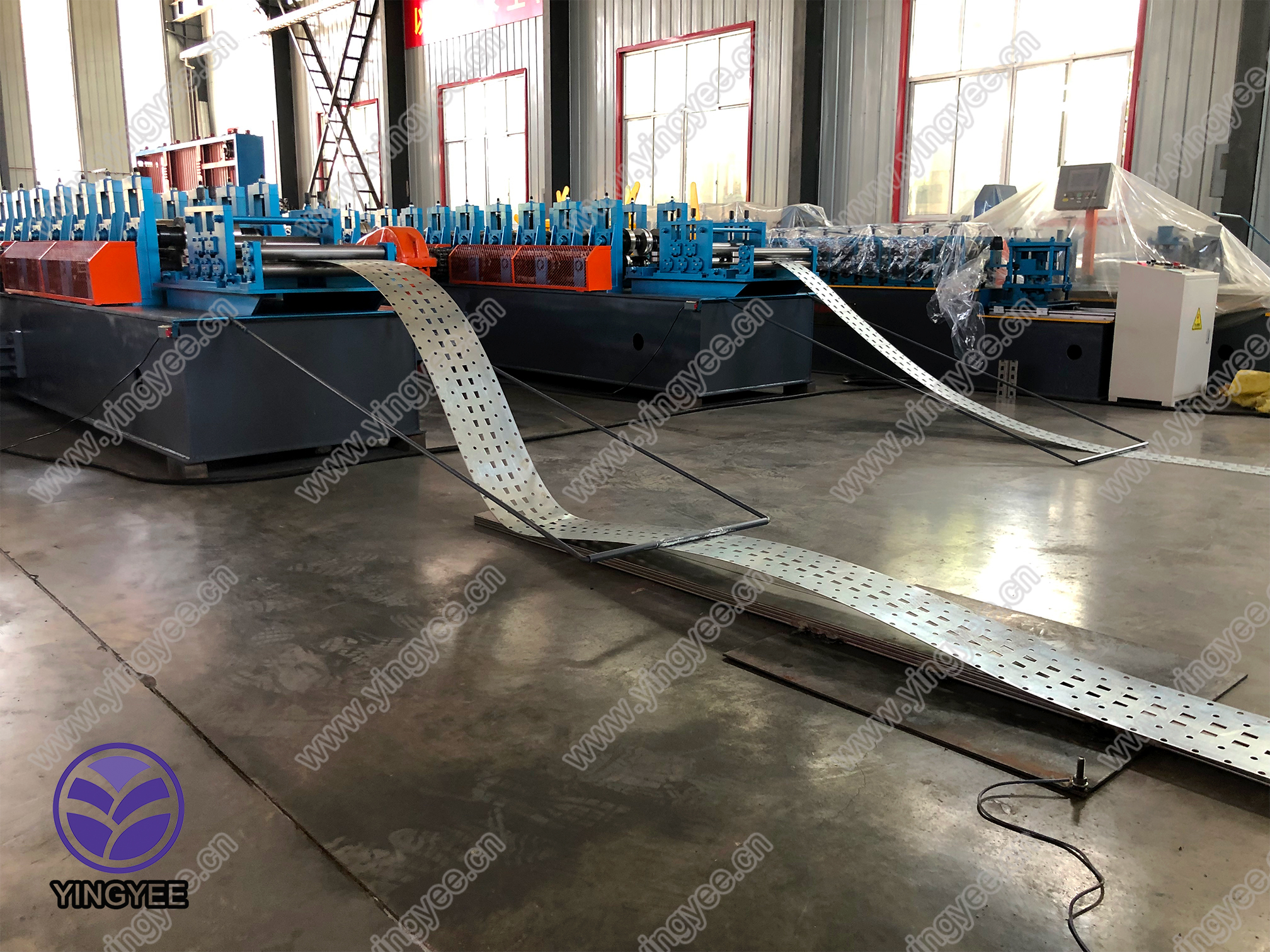

In the scope of expertise, the machine combines multiple processes—uncoiling, flattening, punching, cutting, and roll forming—into a single streamlined operation. This integration not only enhances productivity but also reduces the operational costs significantly by minimizing manual interventions. The technology behind these machines incorporates advanced PLC controls, allowing for customizable operation sequences suited to various project requirements. This level of control ensures that production deadlines are met without compromising on quality, making it an invaluable asset in high-volume manufacturing environments.

The authority of the furring channel roll forming machine in the construction sector stems from its ability to produce profiles with consistent dimensional accuracy. This precision is crucial, particularly in large construction projects where even the smallest deviation can lead to costly rework. By maintaining tight tolerances, these machines uphold structural integrity and ensure safe installations. Moreover, their adaptability to different materials and configurations without sacrificing performance speaks volumes of their robustness and versatility.

furring channel roll forming machine

Trustworthiness is another cornerstone of these machines’ appeal. The machines are built using durable components and cutting-edge technology, ensuring longevity and reliability. Our company, for instance, has successfully deployed these machines across multiple projects with zero downtime over extended periods, attesting to their dependability. Manufacturers offer extensive training and technical support, fostering a relationship of trust with clients who can rely on the machines to deliver results time after time.

In the realm of product development and innovation, the furring channel roll forming machine stands as a paragon of technological advancement. It empowers manufacturers with the capability to swiftly adapt to changing market demands, producing customized channel profiles that serve various architectural designs and load requirements. The machine supports sustainable construction practices by maximizing material usage efficiency and reducing waste, aligning with modern ecological mandates and potentially enhancing a company’s green credentials.

Owning a furring channel roll forming machine represents a strategic investment in quality manufacturing and operational efficiency. Businesses that leverage this equipment gain a significant competitive edge, reducing lead times and increasing output while maintaining the highest quality standards. Furthermore, the economic benefits extend beyond manufacturing, impacting supply chain efficiencies and project turnaround times, ultimately improving customer satisfaction and boosting profitability.

In summary, the furring channel roll forming machine is more than just a piece of equipment; it's a cornerstone of modern construction manufacturing that provides unmatched precision, reliability, and adaptability. Its ability to integrate seamlessly into various manufacturing environments while supporting sustainable practices makes it a crucial investment for any operation aiming to lead in today’s competitive market landscape. Aided by expert support and cutting-edge technology, this machine not only meets the needs of today but is prepared to meet the demands of tomorrow's construction challenges.