Understanding Furring Channel Roll Forming Machines

Furring channel roll forming machines are essential tools in the construction industry, playing a crucial role in the production of furring channels used for various applications, including drywall installation and roofing systems. Furring channels are thin strips of metal or other materials used to create a level surface for attaching drywall, insulation, or other construction materials, ensuring durability and stability in building structures. This article explores the function, features, benefits, and operational principles of furring channel roll forming machines.

What is a Furring Channel Roll Forming Machine?

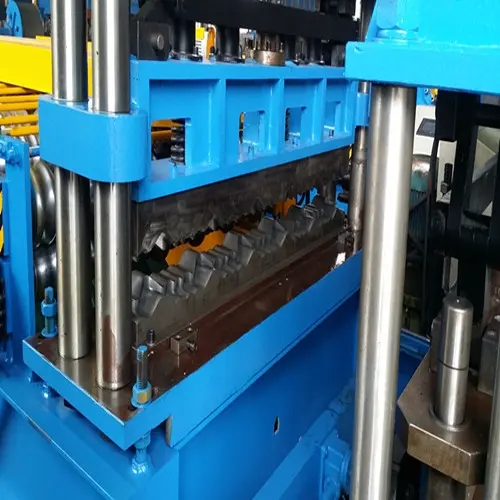

A furring channel roll forming machine is specialized equipment designed to produce furring channels from flat metal sheets. These machines employ a series of rollers that shape the metal into the desired channel profile through a continuous process. The flexibility of the machines allows for the production of various channel sizes and shapes, catering to different construction requirements.

Key Features of Furring Channel Roll Forming Machines

1. High Precision These machines guarantee high precision in the dimensions of the produced channels, ensuring that they fit perfectly during installation. The precision engineering involved minimizes waste and maximizes efficiency.

2. Automatic Control Modern furring channel roll forming machines are equipped with advanced automation systems. Computer numerical control (CNC) technology allows for easy adjustments and programming for different profiles, reducing operator error and improving efficiency.

3. Durable Construction Built from high-quality materials, these machines are designed for longevity. The robust components withstand the stresses of continuous operation, making them suitable for high-volume production environments.

4. Versatility Furring channel roll forming machines can produce various profiles and sizes, making them versatile tools for manufacturing and construction. This adaptability means manufacturers can respond quickly to changing demands in the market.

5. Easy Maintenance With user-friendly designs, maintenance and servicing of these machines are straightforward. Regular maintenance ensures optimal performance and longevity of the equipment.

Advantages of Using Furring Channel Roll Forming Machines

1. Cost-Effectiveness By producing furring channels in-house, companies can significantly reduce costs associated with purchasing pre-manufactured materials. This also allows for better control over material quality.

2. Increased Production Efficiency The automated nature of roll forming machines allows for high-speed production, meeting large-scale demands without compromising quality. This efficiency is particularly beneficial in fast-paced construction environments.

3. Customization Manufacturers can customize furring channels to meet specific requirements for different projects, enhancing customer satisfaction. This customization ability is invaluable in competitive markets where tailored solutions are often necessary.

4. Reduced Waste The precision of the roll forming process minimizes scrap during production, making it an environmentally friendly option. Efficient use of raw materials translates into lower production costs and sustainability benefits.

5. Enhanced Structural Integrity Furring channels produced through roll forming are known for their strength and durability. Consistency in production means that builders can trust the quality of the materials they are using, contributing to the overall safety and integrity of the structures.

How Furring Channel Roll Forming Machines Operate

The operation of a furring channel roll forming machine involves several steps. Initially, flat metal sheets are fed into the machine, where they pass through a series of rollers. Each roller gradually shapes the material until it reaches the final channel profile. After forming, the channels may be cut to specific lengths and prepared for shipping or installation.

In conclusion, furring channel roll forming machines are integral to modern construction processes, offering precision, efficiency, and customization in the production of essential building components. As the construction industry continues to evolve, these machines will play an increasingly vital role in shaping high-quality, reliable structures, making them a worthwhile investment for manufacturers and builders alike. With their ability to streamline production while ensuring high standards, furring channel roll forming machines are indeed pivotal to achieving success in the construction sector.