The Importance of Furring Channel Roll Forming Machines in Modern Construction

In the ever-evolving landscape of modern construction, efficiency and precision are paramount. Among the various innovations revolutionizing the industry, furring channel roll forming machines stand out as an essential tool for builders and contractors. These machines streamline the production of furring channels, which are critical components in the framing of walls, ceilings, and roofs, allowing for improved insulation, soundproofing, and overall structural integrity.

Understanding Furring Channels

Furring channels, typically made of galvanized steel, are lightweight metal strips used to create an airspace between the walls or ceilings and the surface materials such as drywall. This airspace is crucial for accommodating insulation and preventing moisture buildup, which can lead to mold and decay. Additionally, the use of furring channels helps to level uneven surfaces and can facilitate the installation of electrical wiring and plumbing, making them indispensable in both residential and commercial construction projects.

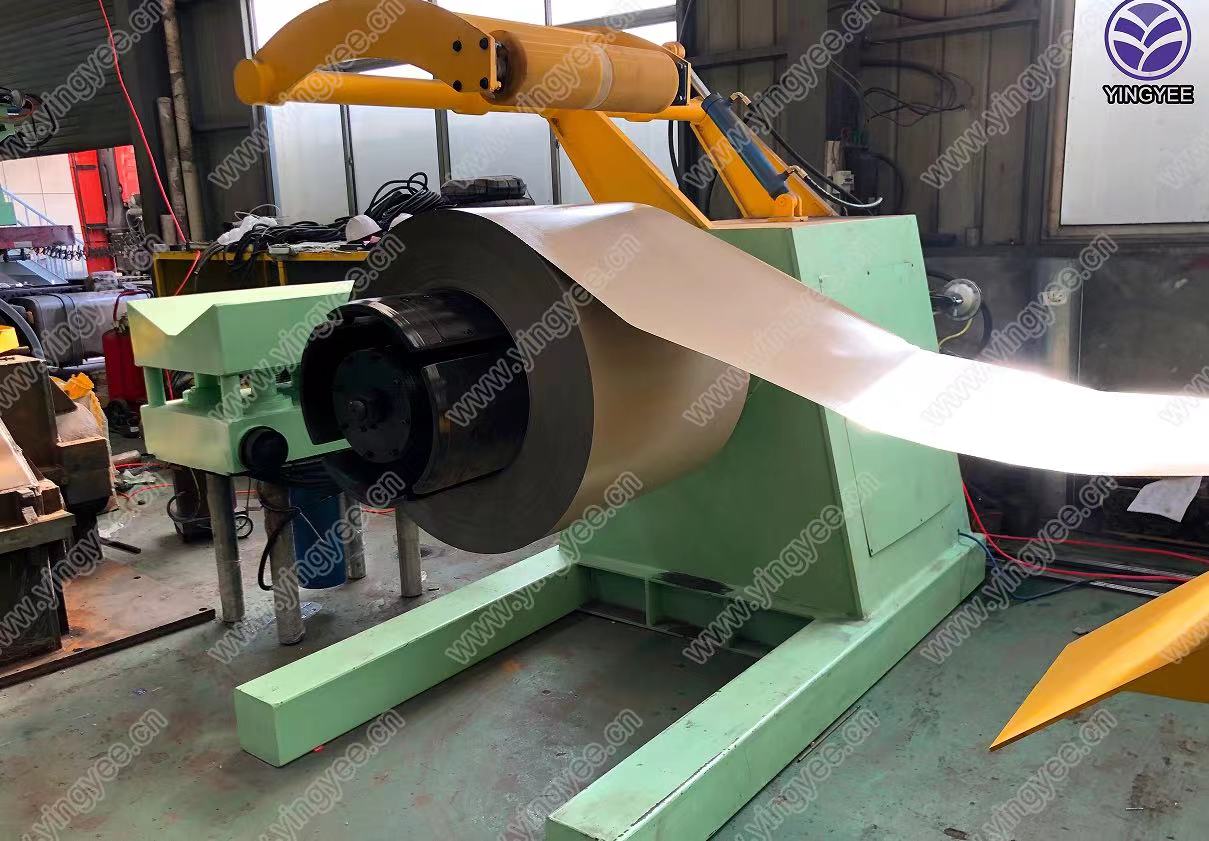

The Role of Roll Forming Machines

Roll forming machines are specialized equipment designed to transform flat metal sheets into specific profiles through a continuous bending process. Furring channel roll forming machines, in particular, are tailored to produce furring channels with high precision and efficiency. The process involves feeding a coil of steel into the machine, which then passes through a series of rollers that gradually shape the metal into the desired channel profile.

One of the key advantages of using a furring channel roll forming machine is the ability to produce channels with consistent dimensions and tolerance levels. This uniformity is crucial for maintaining construction standards and ensuring that all components fit together seamlessly during installation. Moreover, the speed of the roll forming process allows manufacturers to keep up with the increasing demand for furring channels in the construction industry.

Benefits of Automatic Systems

Modern furring channel roll forming machines often incorporate advanced technology, including computer numerical control (CNC) systems, which enhance their capabilities. These machines can be programmed to produce channels of varying lengths and specifications with minimal manual intervention. This automation not only increases production efficiency but also reduces the likelihood of human error, further ensuring the quality and reliability of the final product.

Additionally, automated systems often have features such as quick-change setups and integrated cutting mechanisms, allowing manufacturers to switch between different profiles without significant downtime. This versatility is particularly beneficial for businesses that need to cater to diverse project requirements and customize solutions for specific applications.

Application in Construction

The versatility and efficiency of furring channel roll forming machines have made them integral to various construction applications. In commercial buildings, these channels are routinely used in drywall installations, suspended ceilings, and interior partitions. Their lightweight nature and structural reliability make them ideal for creating spaces that require both aesthetic appeal and functional performance.

Moreover, with an increasing focus on sustainable building practices, the use of materials such as galvanized steel in furring channels aligns with eco-friendly construction standards. These machines not only contribute to the efficient production of materials but also support the global shift towards sustainability by enabling the reuse and recycling of metal.

Conclusion

The furring channel roll forming machine is more than just a piece of equipment; it is a crucial element in modern construction, enhancing productivity while ensuring high-quality standards. As construction projects become more complex and demanding, the reliance on advanced roll forming technology will continue to grow. Ultimately, these machines play a vital role in shaping the future of construction, allowing builders to meet the challenges of today and tomorrow with confidence.