Furring Channel Roll Forming Machine Enhancing Construction Efficiency

In the realm of modern construction, the use of metal framing systems has become increasingly popular due to their durability, cost-effectiveness, and lightweight properties. One key component of these systems is the furring channel, which serves as a critical support structure for various applications, including walls, ceilings, and shelving. To streamline the production of furring channels, the furring channel roll forming machine has emerged as an essential tool, revolutionizing the way builders and manufacturers approach metal framing.

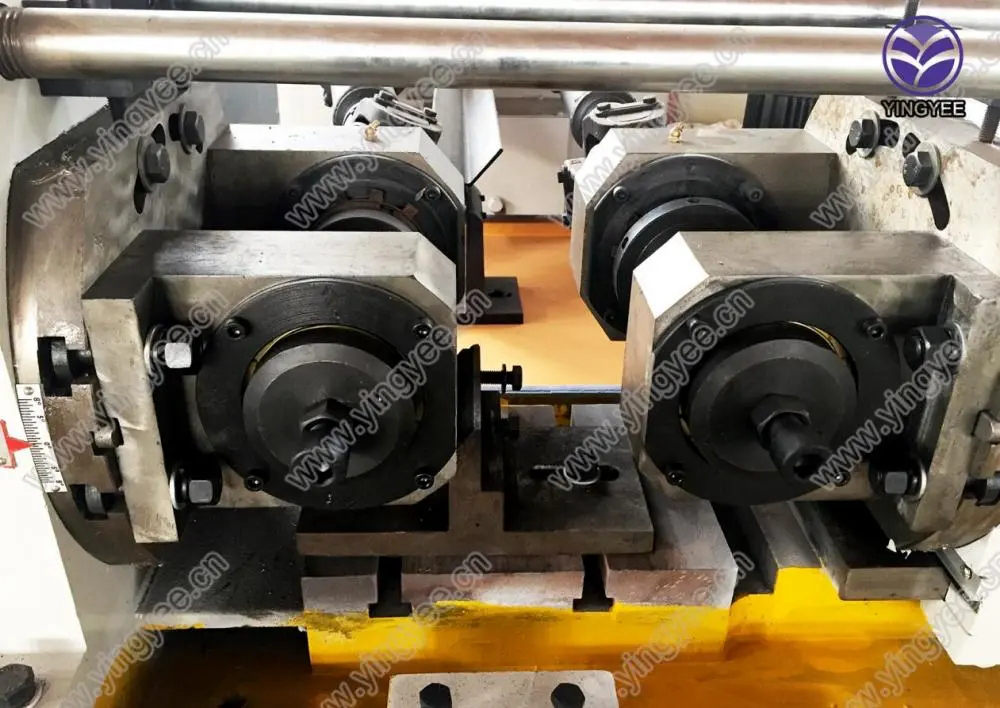

A furring channel roll forming machine is designed to convert flat metal sheets into specifically shaped furring channels through a series of precise mechanical processes. These machines utilize advanced technology to ensure high levels of accuracy and consistency in the final product. The process begins with feeding a coil of metal into the machine, where it is then roll-formed into the desired profile. This method not only speeds up production but also reduces material wastage, making it an environmentally friendly choice.

One of the standout features of a furring channel roll forming machine is its versatility. Manufacturers can adjust the machine to produce various sizes and profiles of furring channels based on the specific requirements of a project. Moreover, the machine can accommodate different materials, such as galvanized steel or aluminum, to meet varying structural needs. This flexibility allows contractors to efficiently manage inventory and customize framing solutions for different construction projects.

Furthermore, the efficiency of the furring channel roll forming machine can significantly reduce labor costs. Traditional methods of fabricating furring channels often require manual labor and time-consuming processes. By automating this production step, companies can not only save on labor but also allocate resources to other areas of construction, increasing overall productivity. This enhancement in efficiency is particularly crucial in large-scale projects where time is of the essence.

In addition to efficiency and cost savings, using a roll forming machine for furring channels ensures high-quality products. The continuous nature of the roll forming process minimizes imperfections that can occur with alternative fabrication methods. As a result, contractors receive uniform furring channels that adhere to industry standards and provide reliable support for various applications.

Moreover, the integration of technological advancements such as computer numerical control (CNC) systems has further improved the capabilities of furring channel roll forming machines. These systems allow for real-time monitoring and adjustments during the production process, ensuring that any deviations from specifications are promptly addressed. This level of precision not only enhances the quality of the furring channels but also contributes to the overall safety and integrity of the construction projects.

In conclusion, the furring channel roll forming machine plays a pivotal role in modern construction by enhancing efficiency, reducing costs, and ensuring high-quality manufacturing of furring channels. As the construction industry continues to evolve, the adoption of advanced machinery like this will be crucial in meeting the growing demand for reliable and efficient building solutions. The benefits of utilizing a furring channel roll forming machine extend beyond just improved productivity; they signify a shift towards smarter, more sustainable construction practices that can shape the future of the industry.