Understanding Furring Channel Roll Forming Machines

Furring channel roll forming machines play a critical role in the construction industry, particularly in the creation of lightweight steel framing systems. These machines are designed to produce furring channels, which are crucial for supporting wall panels, ceilings, and other structures in a variety of applications. In this article, we will explore the functionality, benefits, and applications of furring channel roll forming machines.

What is a Furring Channel?

A furring channel is a type of metal framing component, usually made from galvanized steel or other durable materials. It is primarily used to create a flat surface for attaching drywall, insulation panels, or other materials. Furring channels can also be employed in acoustic applications, as they help reduce sound transmission in multi-story buildings.

The Role of Roll Forming Machines

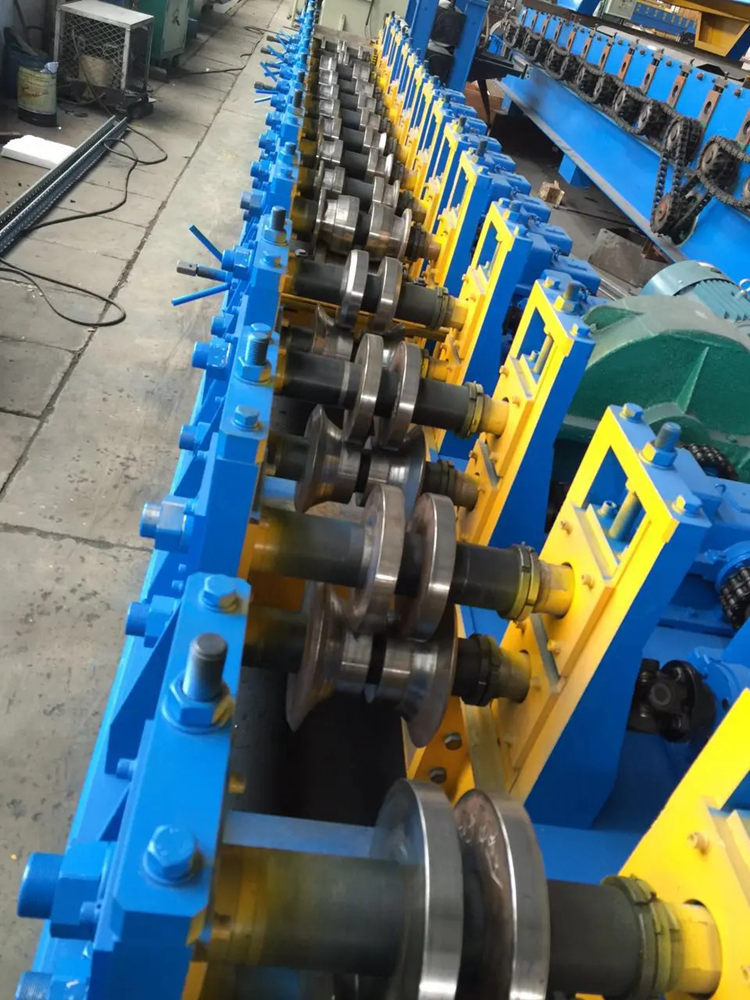

Roll forming is a continuous bending process in which a long strip of sheet metal is passed through consecutive pairs of rolls that progressively shape the material into a desired profile. Furring channel roll forming machines are specialized equipment that create furring channels by bending and shaping steel sheets into the required cross-sectional shape.

These machines generally consist of several key components, including a coil holder, an uncoiler, forming rollers, cutting mechanisms, and a control system. The process begins with feeding a coil of metal into the machine, which is then uncoiled and fed through a series of rollers. As the metal passes through each set of rollers, it is gradually shaped into the furring channel profile. Upon reaching the desired length, the machine cuts the length to ensure consistency in production.

Benefits of Using Furring Channel Roll Forming Machines

1. Efficiency Roll forming machines have the capability to produce large quantities of furring channels at a rapid pace. This efficiency is vital for meeting the demands of large construction projects, helping to keep timelines on track.

2. Consistency and Quality The automated nature of roll forming ensures that each furring channel produced is consistent in dimensions and quality. This uniformity minimizes waste and allows for precise installation.

3. Versatility Furring channel roll forming machines can be adjusted to create different profiles and sizes, making them suitable for a variety of applications. Manufacturers can customize the machinery to meet specific project requirements.

4. Cost-Effectiveness By increasing production efficiency and reducing material waste, these machines help to cut costs. Moreover, the durability of the final product reduces the need for frequent replacements or repairs.

Applications in Construction

Furring channels are widely used in both commercial and residential construction. They provide a framework for hanging drywall, supporting insulation, and creating ceilings. Additionally, their structural properties make them ideal for use in high-rise buildings, where space and weight considerations are critical.

In conclusion, furring channel roll forming machines are indispensable in modern construction practices. They provide efficient, high-quality solutions for creating the metal framing components essential to various building applications. As technology continues to evolve, these machines will only become more advanced, further enhancing their utility in the construction industry.