Fully Automatic Cable Tray Cold Roll Forming Revolutionizing the Cable Management Industry

In today's fast-paced industrial environment, efficient cable management is vital for ensuring safety, reliability, and scalability in electrical installations. One of the most innovative advancements in this field is the fully automatic cable tray cold roll forming system. This technology not only enhances production efficiency but also improves the overall quality of cable trays utilized in various applications, from commercial buildings to industrial plants.

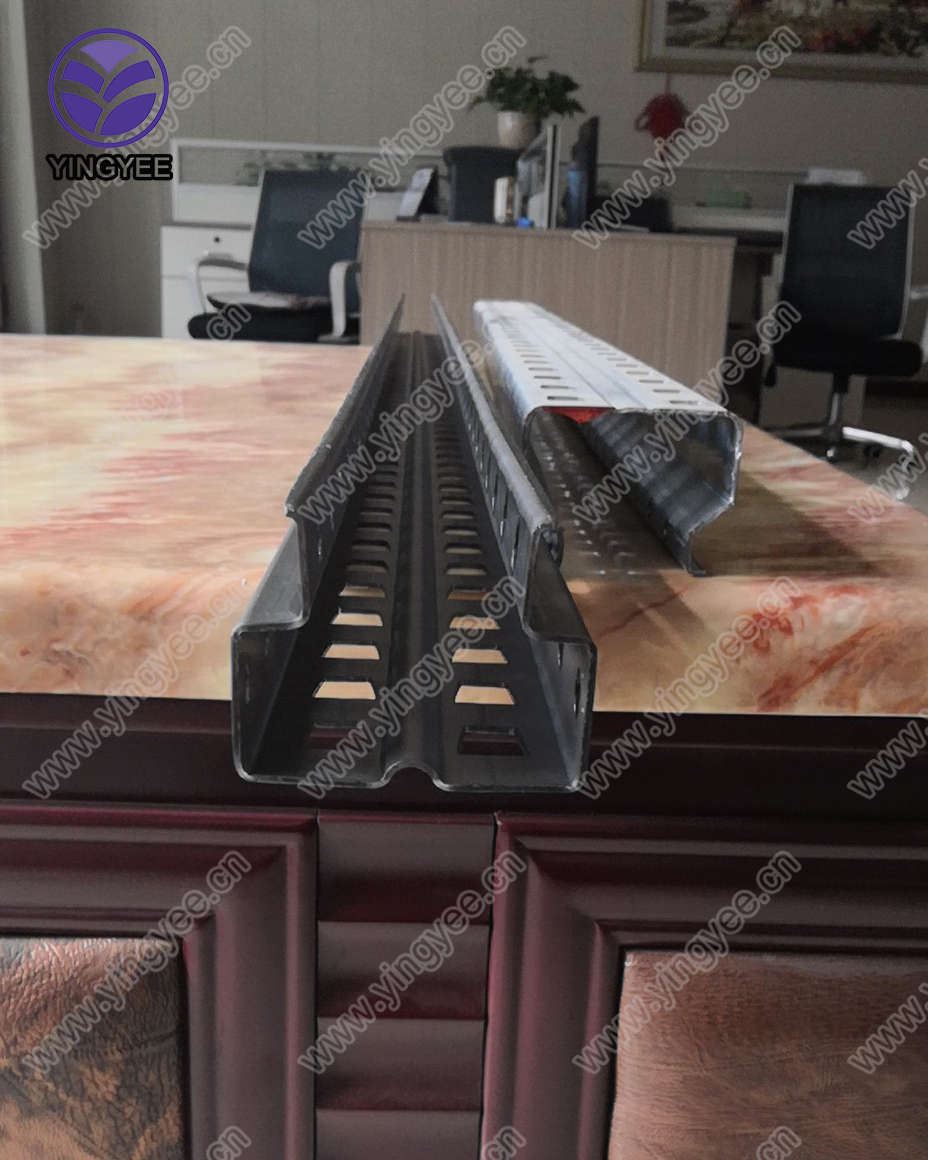

Cold roll forming is a manufacturing process that involves shaping metal sheets into desired profiles at room temperature, which helps preserve the material's integrity. When it comes to cable trays, this technique offers several advantages, including reduced material waste, enhanced strength, and a professional finish. The automatic nature of these systems further adds to their appeal, allowing for higher output and reduced labor costs.

A fully automatic cable tray cold roll forming machine can streamline the entire production process. It typically includes features such as automatic feeding, cutting, and bending stations, all integrated into a single unit. This means that once the parameters for the desired cable tray specifications are set, the machine can operate independently, producing consistent and accurate components at high speeds. This level of automation significantly reduces the likelihood of human error, ensuring that each cable tray meets stringent quality standards.

One of the key benefits of fully automatic systems is their flexibility. Manufacturers can easily adjust the machine settings to accommodate different designs, sizes, and specifications of cable trays without extensive downtime. This adaptability responds to the growing demand for customized solutions in cable management. Companies are increasingly seeking tailor-made cable trays that fit specific installation needs, and a fully automatic cold roll forming machine can pivot to meet these demands with ease.

Furthermore, using cold roll forming technology results in stronger cable trays compared to traditional manufacturing methods. The process enhances the mechanical properties of the material, resulting in products that can withstand greater loads and environmental stresses. This durability is crucial in settings where cable trays are subjected to heavy equipment or outdoor conditions, assuring customers that their investments are protected over time.

In addition to the operational benefits, fully automatic cable tray cold roll forming systems contribute to environmental sustainability. The precision of the cold roll forming process minimizes waste, as it produces components that require fewer additional processes like welding or machining. Many manufacturers are also adopting eco-friendly materials, further aligning with global sustainability goals.

The market demand for fully automatic cold roll forming solutions continues to grow. As industries become more aware of the importance of proper cable management, the need for efficient, reliable, and high-quality cable trays is on the rise. Innovative technology in manufacturing not only fulfills these needs but also enhances production processes, leading to increased competitiveness in the market.

In conclusion, the fully automatic cable tray cold roll forming system represents a significant leap in cable management technology. By delivering higher efficiency, customized solutions, material strength, and sustainability, this innovative approach is set to transform how industries manage their electrical installations. As demand continues to rise, manufacturers equipped with this advanced technology will undoubtedly lead the charge towards a more organized and safe electrical infrastructure.