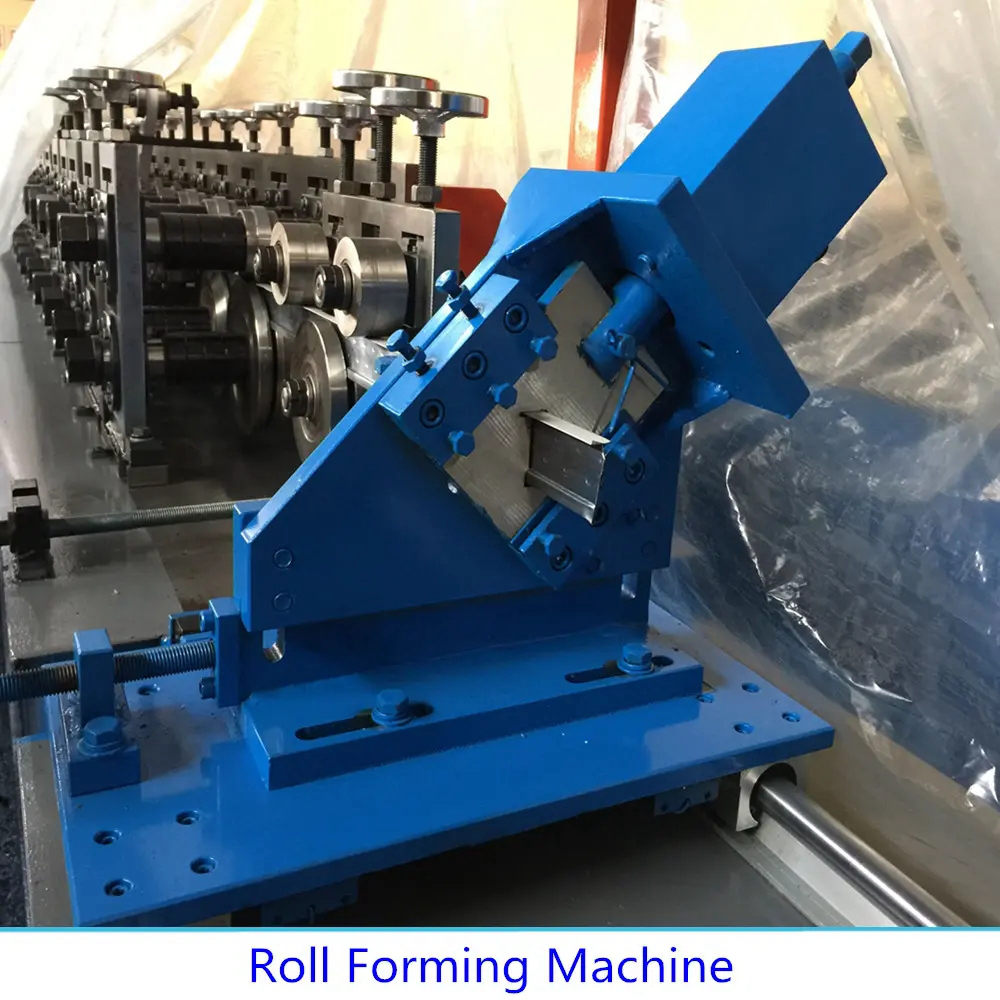

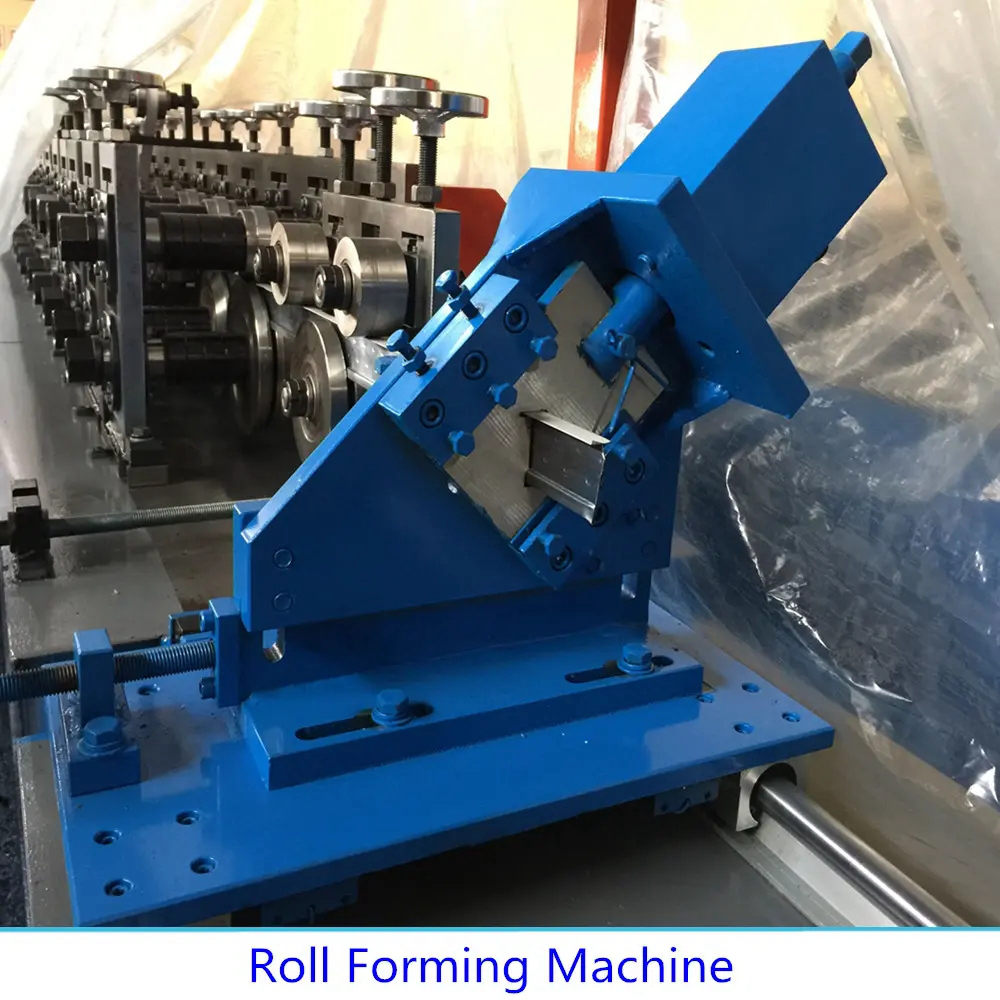

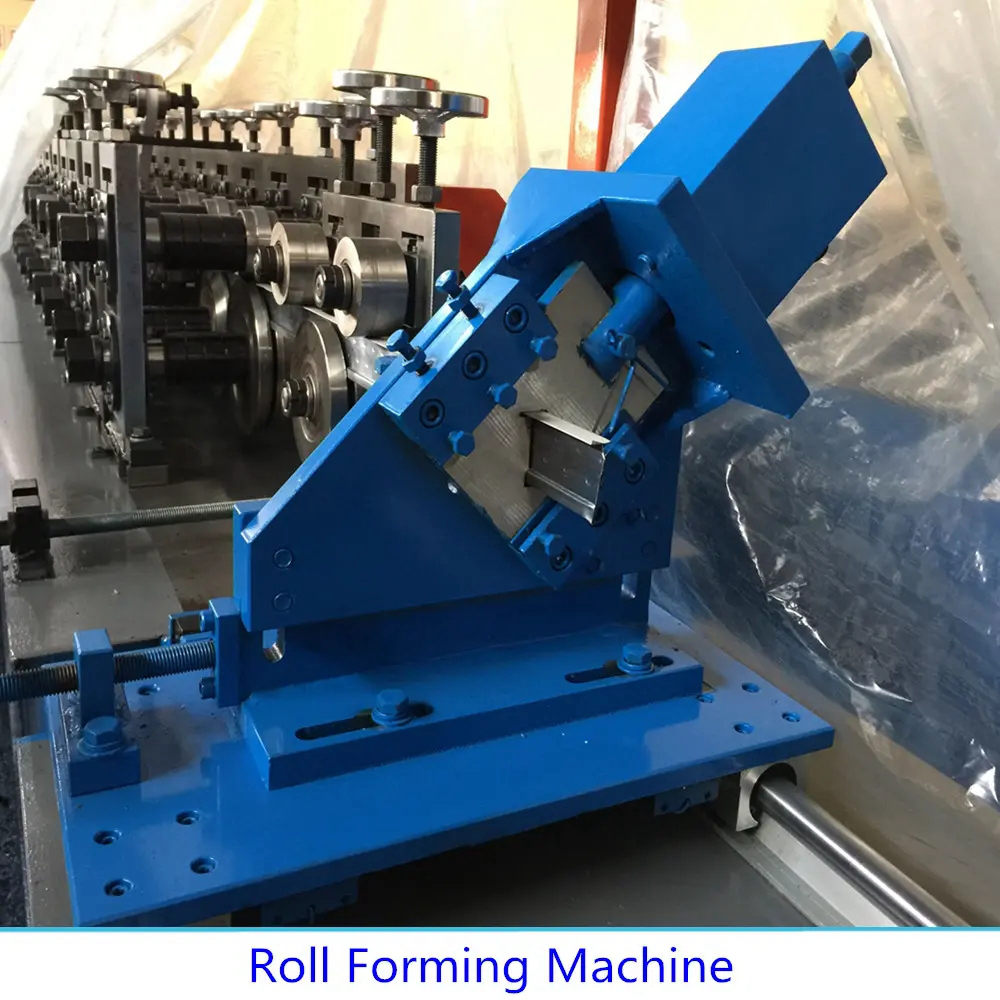

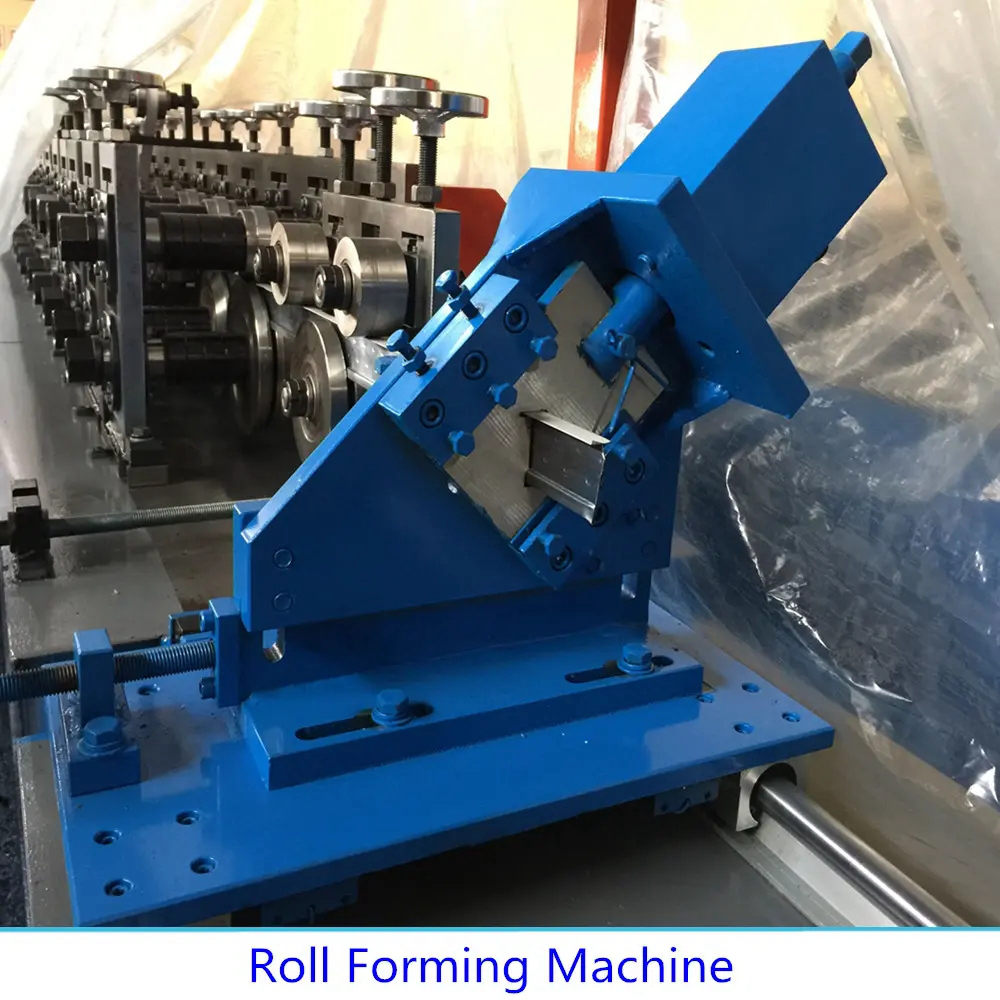

The u channel furring forming machine is an essential piece of equipment in the construction industry. This machine is used to create U-shaped channels, which are important components in framing systems for ceilings and walls. By using a u channel furring forming machine, construction companies are able to produce these channels quickly and efficiently, helping to speed up the building process.

The u channel furring forming machine works by taking a coil of metal and feeding it through a series of rollers and dies. These rollers and dies bend and shape the metal into the desired U-shaped channel, which can then be cut to the appropriate length. This machine can produce channels of various sizes and shapes, depending on the specific requirements of the construction project.

One of the main advantages of using a u channel furring forming machine is the speed at which channels can be produced. Traditional methods of forming these channels by hand can be time-consuming and labor-intensive. By using a machine to do the work, construction companies are able to increase their productivity and complete projects more quickly.

In addition to speed, u channel furring forming machines also offer precision and consistency in the production process

In addition to speed, u channel furring forming machines also offer precision and consistency in the production process

In addition to speed, u channel furring forming machines also offer precision and consistency in the production process

In addition to speed, u channel furring forming machines also offer precision and consistency in the production process

u channel furring forming machine

u channel furring forming machine. The rollers and dies of the machine are carefully calibrated to ensure that each channel is formed to the exact specifications required. This helps to minimize errors and waste, resulting in higher-quality channels for use in construction.

Furthermore, using a u channel furring forming machine can help to reduce costs for construction companies. By producing channels in-house, companies can save on the expense of purchasing pre-formed channels from suppliers. Additionally, the efficiency of the machine means that fewer labor hours are required to produce the channels, leading to further cost savings.

Overall, the u channel furring forming machine is a valuable tool for construction companies looking to streamline their processes and increase productivity. By investing in this machine, companies can save time, reduce costs, and improve the quality of the channels used in their projects.

In addition to speed, u channel furring forming machines also offer precision and consistency in the production process

In addition to speed, u channel furring forming machines also offer precision and consistency in the production process

In addition to speed, u channel furring forming machines also offer precision and consistency in the production process

In addition to speed, u channel furring forming machines also offer precision and consistency in the production process u channel furring forming machine. The rollers and dies of the machine are carefully calibrated to ensure that each channel is formed to the exact specifications required. This helps to minimize errors and waste, resulting in higher-quality channels for use in construction.

Furthermore, using a u channel furring forming machine can help to reduce costs for construction companies. By producing channels in-house, companies can save on the expense of purchasing pre-formed channels from suppliers. Additionally, the efficiency of the machine means that fewer labor hours are required to produce the channels, leading to further cost savings.

Overall, the u channel furring forming machine is a valuable tool for construction companies looking to streamline their processes and increase productivity. By investing in this machine, companies can save time, reduce costs, and improve the quality of the channels used in their projects.

u channel furring forming machine. The rollers and dies of the machine are carefully calibrated to ensure that each channel is formed to the exact specifications required. This helps to minimize errors and waste, resulting in higher-quality channels for use in construction.

Furthermore, using a u channel furring forming machine can help to reduce costs for construction companies. By producing channels in-house, companies can save on the expense of purchasing pre-formed channels from suppliers. Additionally, the efficiency of the machine means that fewer labor hours are required to produce the channels, leading to further cost savings.

Overall, the u channel furring forming machine is a valuable tool for construction companies looking to streamline their processes and increase productivity. By investing in this machine, companies can save time, reduce costs, and improve the quality of the channels used in their projects.