Understanding the Floor Deck Tile Roll Forming Machine

In the realm of modern construction, efficiency and precision in material production are paramount. One essential tool that has gained prominence is the floor deck tile roll forming machine. This sophisticated piece of equipment is designed to produce high-quality floor deck tiles through a continuous process of roll forming, ultimately contributing to more efficient construction practices and enhanced structural integrity.

What is a Floor Deck Tile Roll Forming Machine?

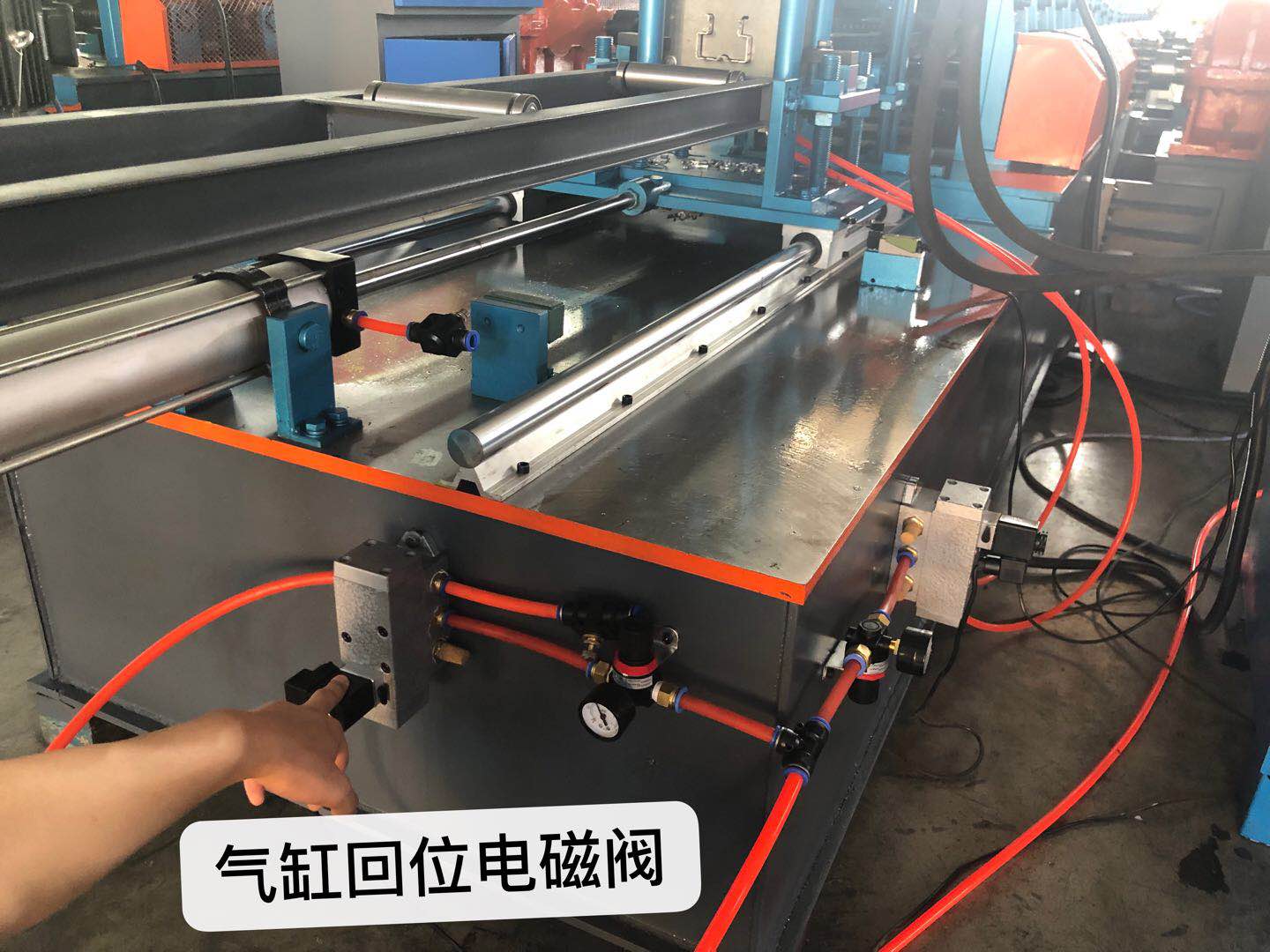

A floor deck tile roll forming machine is a specialized industrial machine used to create floor deck tiles from various materials, most commonly steel. The process begins with flat metal sheets, which are fed into the machine. As these sheets pass through a series of rollers, they are gradually shaped into the desired profile of floor tiles. The machine's technology allows for precise dimensions, ensuring that each tile fits seamlessly into construction assemblies.

The typical roll forming process involves several stages, starting from initial feeding and edging to the actual forming and cutting of tiles. The machine’s setup allows for customization of the tile profile according to project specifications, making it versatile for various applications in commercial and residential buildings.

Advantages of Using Floor Deck Tile Roll Forming Machines

1. Speed and Efficiency One of the most significant advantages of using a roll forming machine is the speed at which tiles can be produced. With continuous operation, large quantities of tiles can be manufactured in a fraction of the time it would take using traditional methods. This efficiency helps in meeting tight construction deadlines without compromising on quality.

2. Consistent Quality The automated nature of roll forming machines ensures a high level of consistency in the production process. Each tile produced has the same dimensions and specifications, which is crucial for structural integrity and aesthetic appeal in construction projects.

3. Cost-Effectiveness Although the initial investment in a roll forming machine can be substantial, the long-term savings are significant. The reduction in labor costs, decreased waste, and the ability to produce tiles on-demand contribute to lower overall production costs.

4. Material Versatility Floor deck tile roll forming machines can process various materials, including different grades of steel and aluminum. This adaptability allows manufacturers to cater to a wide range of client needs, from lightweight materials for residential applications to heavy-duty solutions for industrial projects.

5. Eco-Friendly Production With a growing emphasis on sustainability, using a roll forming machine can be an environmentally friendly choice. The precise cutting and forming processes minimize waste, and the ability to produce tiles from recyclable materials reduces the overall carbon footprint.

Applications in Construction

Floor deck tiles produced by roll forming machines are used widely in construction. They serve as structural flooring solutions, particularly in high-rise buildings, warehouses, and commercial properties. Their ability to support heavy loads while providing a lightweight option makes them ideal for various applications.

In addition to structural uses, floor deck tiles can also be aesthetically pleasing, with numerous finishes and coatings available. This means that they not only serve a structural purpose but also enhance the overall design of a building.

Conclusion

In conclusion, the floor deck tile roll forming machine represents a significant advancement in construction technology. By combining speed, efficiency, and versatility, it meets the demands of modern construction practices while providing high-quality products. As the construction industry continues to evolve, investing in this technology will help manufacturers stay competitive, meet client demands, and contribute to sustainable building practices. Understanding the capabilities and benefits of these machines can thus inform better decision-making for businesses in the construction sector.