Expressway Guard Rail Roll Forming Machine Ensuring Safety on Roads

As urbanization and global travel continue to rise, maintaining road safety has become a paramount concern for governments and infrastructure developers worldwide. One vital component of road safety is the guard rail, which acts as a barrier to prevent vehicles from veering off the road and provides protection for both drivers and pedestrians. The production of sturdy and reliable guard rails requires advanced technology, and this is where the expressway guard rail roll forming machine comes into play.

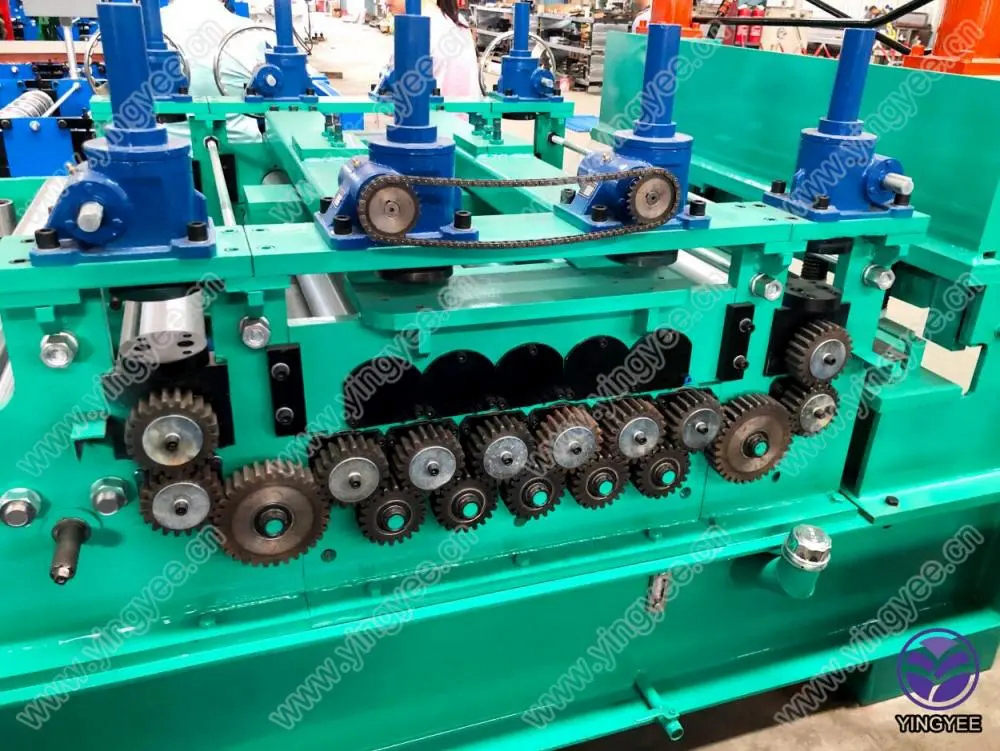

The expressway guard rail roll forming machine is a state-of-the-art piece of equipment designed to manufacture guard rails with precision and efficiency. Utilizing a continuous forming process, the machine transforms flat steel sheets into strong and durable guard rails that can withstand the impact of vehicles. The process begins with the loading of raw steel coils onto the machine, where they undergo a series of forming operations. As the steel passes through various rollers, it is shaped into the desired profile, ensuring consistency and quality throughout the production run.

One of the significant advantages of using a roll forming machine for guard rail production is its efficiency. Traditional methods of manufacturing guard rails often involve a lot of manual labor and lead to inconsistencies in product quality. However, the roll forming process significantly reduces labor costs and production time, allowing manufacturers to meet high demand while maintaining excellent quality standards. This efficiency becomes especially crucial when dealing with large-scale projects such as highways and expressways, where a continuous supply of guard rails is needed.

In addition to efficiency, the expressway guard rail roll forming machine is designed with durability and flexibility in mind. Depending on the requirements of a specific project, manufacturers can adjust the machine to produce various guard rail profiles and sizes. This adaptability allows for customization to meet region-specific safety standards and designs, ensuring that the guard rails not only function effectively but also blend seamlessly into the surrounding environment.

Moreover, environmental considerations are increasingly important in today's production processes. Many advanced roll forming machines are designed to minimize waste and improve energy efficiency, aligning with global efforts to promote sustainable manufacturing practices.

In conclusion, the expressway guard rail roll forming machine plays a crucial role in enhancing road safety by producing high-quality guard rails with efficiency and precision. As the demand for safer roads continues to rise, investing in modern roll forming technology is not just a business decision but a commitment to protecting lives. With continuous advancements in manufacturing technologies, the future of guard rail production looks promising, paving the way for safer travel on expressways and highways worldwide.