Knudson Rollforming Revolutionizing Metal Fabrication

The manufacturing landscape has evolved significantly over the years, with advancements in technology playing a crucial role in shaping industries. One notable innovation in the field of metal fabrication is rollforming, a technique that has garnered attention for its efficiency and precision. Among the leaders in this domain, Knudson Rollforming stands out as a pioneer, consistently delivering high-quality solutions for various applications.

Understanding Rollforming

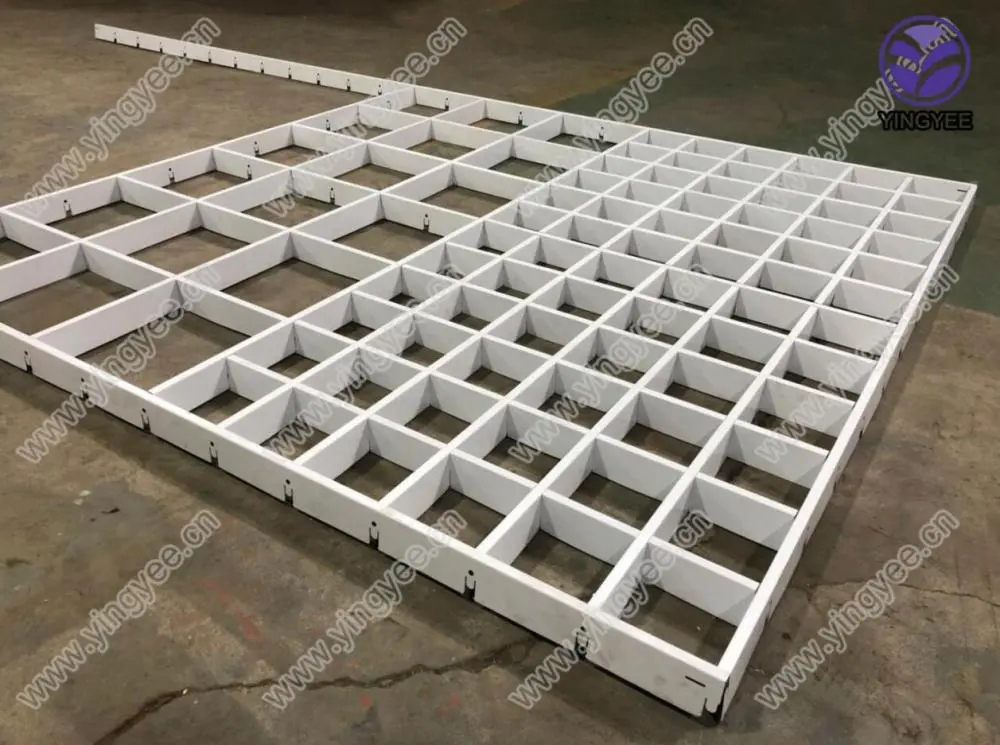

Rollforming is a continuous bending process that involves feeding flat metal sheets through a series of mechanical rollers to create a specific cross-sectional shape. This process is particularly favored for producing long lengths of parts in a cost-effective and efficient manner. The method is characterized by its ability to maintain tight tolerances, uniformity, and high production rates.

Knudson Rollforming A Brief Overview

Founded with a vision to innovate metalworking, Knudson Rollforming has established itself as a key player in the rollforming sector. With years of experience and a commitment to quality, the company has excelled in providing tailored rollform solutions that meet the unique needs of various industries, including construction, automotive, and aerospace.

Unmatched Precision and Quality

One of the standout features of Knudson Rollforming is its unwavering dedication to precision. Utilizing state-of-the-art engineering and design software, the company ensures that each rollformed product adheres to strict specifications. This level of precision is crucial, especially in industries where even minute deviations can lead to significant issues downstream.

Knudson employs advanced quality control measures at every stage of the production process. From raw material selection to post-production inspection, every component undergoes rigorous testing to ensure it meets industry standards and customer expectations. This commitment to quality has earned Knudson a reputation for reliability and excellence, making it a preferred supplier for many high-profile clients.

Versatility Across Industries

One of the key advantages of rollforming is its versatility, and Knudson Rollforming capitalizes on this strength. The company offers a diverse range of products, including structural shapes, custom profiles, and specialized components that are adaptable to various applications. Whether it’s metal roofing systems, wall panels, or automotive parts, Knudson’s expertise enables them to provide solutions that enhance durability and performance.

In addition to standard products, Knudson is known for its ability to create custom rollforming solutions. This capability allows them to collaborate closely with clients, offering prototypes and tailored designs that meet specific project requirements. The team at Knudson works diligently to ensure seamless integration of their products into the client’s applications, further cementing their position as an industry leader.

Sustainability and Future Prospects

As the world becomes increasingly aware of environmental issues, sustainability in manufacturing is more important than ever. Knudson Rollforming is committed to reducing waste and improving energy efficiency in its operations. By optimizing the rollforming process and utilizing sustainable materials, the company aims to minimize its environmental footprint while delivering high-quality products.

Looking ahead, Knudson Rollforming continues to explore new technologies and methodologies to enhance its offerings. The integration of automation and advanced manufacturing techniques is on the horizon, promising to further improve efficiency and reduce lead times for customers.

Conclusion

Knudson Rollforming represents a fusion of tradition and innovation in the metal fabrication industry. With a relentless focus on quality, precision, and customer satisfaction, the company is poised to lead the way in rollforming technology. As industries evolve and demand for advanced materials and solutions increases, Knudson Rollforming stands ready to meet the challenges of the future, reinforcing its legacy as a trusted partner in metal fabrication.