Understanding ERW Carbon Steel Tube Mills A Comprehensive Overview

Electrowelded (ERW) carbon steel tube mills have revolutionized the way steel tubes and pipes are produced. These mills utilize advanced technology to create high-quality steel tubes that are essential for various applications across multiple industries, including construction, automotive, manufacturing, and energy. This article delves into the operational principles, advantages, and applications of ERW carbon steel tube mills.

What is ERW Steel?

ERW stands for Electric Resistance Welding, which is a process used to produce longitudinally welded tubes and pipes. The process involves the following key steps the roll forming of steel strips to the desired shape, the application of electrical current, and the joining of the edges through resistance welding. Once the strip is shaped into a tube, high-frequency electrical currents are passed through its edges, generating heat. The molten edges are then fused together under pressure, resulting in a strong, continuous weld.

The Operation of ERW Carbon Steel Tube Mills

ERW tube mills are typically designed with multiple sections, each serving a specific function in the production process. The primary components of an ERW tube mill include

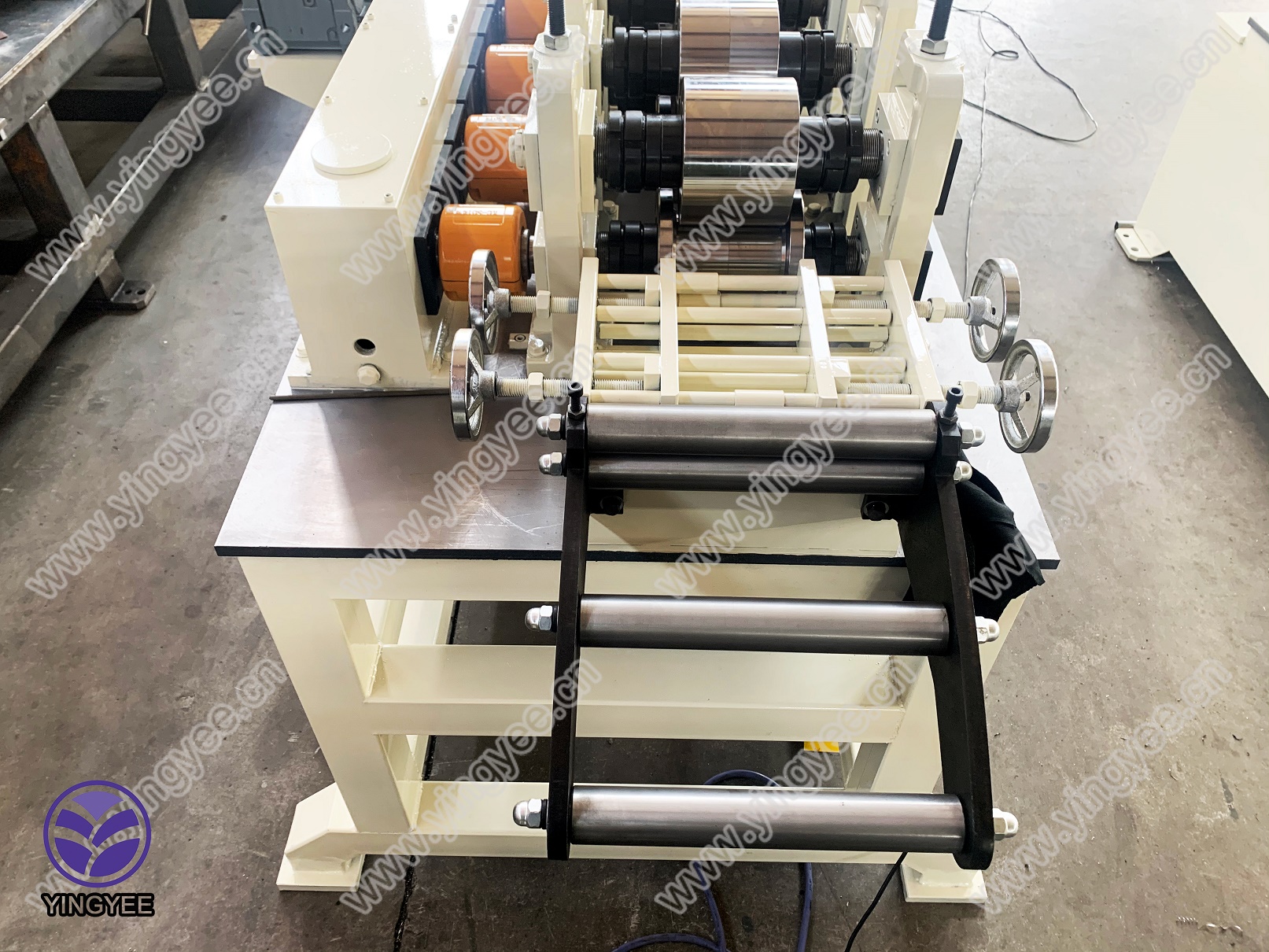

1. Strip Preparation This section involves the uncoiling and leveling of steel strips to ensure a smooth and uniform surface for welding.

2. Forming Station The steel strips are then shaped into a tubular form using a series of forming rolls. This step is crucial as it defines the final dimensions and shape of the pipe.

3. Welding Station Once the strip is formed into a tube, the edges are aligned and passed through the welding station, where electric resistance welding takes place. The heat generated at the edges facilitates a strong weld without the need for additional filler materials.

4. Sizing and Straightening After welding, the tube may undergo sizing and straightening processes to ensure it meets the required specifications for diameter and roundness.

5. Cutting and Finishing Finally, the welded tubes are cut to the desired lengths and may undergo additional treatments such as galvanization or coating, depending on their intended use.

Advantages of ERW Carbon Steel Tube Mills

The ERW process offers several distinct advantages over traditional pipe manufacturing methods

- Cost-Effectiveness ERW tube mills are more economical due to lower production costs and reduced waste material. The process allows for the use of thinner steel strips without compromising strength.

- High Speed and Efficiency ERW mills are designed for high-speed production, enabling manufacturers to produce large volumes of tubes in shorter time frames.

- Quality Control The welded seam in ERW pipes is often more consistent and uniform compared to other welding methods. This results in better quality control and inspection techniques.

- Versatility ERW carbon steel tubes can be manufactured in a variety of sizes and thicknesses, making them suitable for diverse applications ranging from structural use in buildings to energy transport in pipelines.

Applications of ERW Carbon Steel Tubes

ERW carbon steel tubes are incredibly versatile and are used across numerous industries. Common applications include

- Construction These tubes are extensively used in structural applications, providing support and framework for buildings and other infrastructure projects.

- Pipeline Infrastructure ERW tubes serve as crucial components in the transportation of oil, gas, and other liquids, offering a reliable solution for pipeline systems.

- Automotive Industry In the automotive sector, ERW tubes are used for manufacturing frame components, roll cages, and other structural elements that require high strength and durability.

- Furniture Manufacturing ERW tubes are also utilized in the production of metal furniture items, thanks to their aesthetic appeal and structural integrity.

Conclusion

ERW carbon steel tube mills represent a significant advancement in the manufacturing of steel tubes and pipes. Their efficiency, cost-effectiveness, and versatility make them a preferred choice for many industries. As technology continues to evolve, it is anticipated that ERW tube mills will further improve in performance and quality, continuing to support infrastructure and industrial growth worldwide. The future of steel tube production is bright, and ERW technology will play a crucial role in meeting the demands of various applications.