The Evolution of Elbow Forming Machine Manufacturers

Elbow forming machines play a critical role in the fabrication of piping systems across various industries, including oil and gas, construction, and manufacturing. As the demand for efficient and high-quality piping solutions continues to rise, the significance of elbow forming machine manufacturers cannot be overstated. These manufacturers not only contribute to the production of essential infrastructure but also bring innovation and efficiency to the fabrication process.

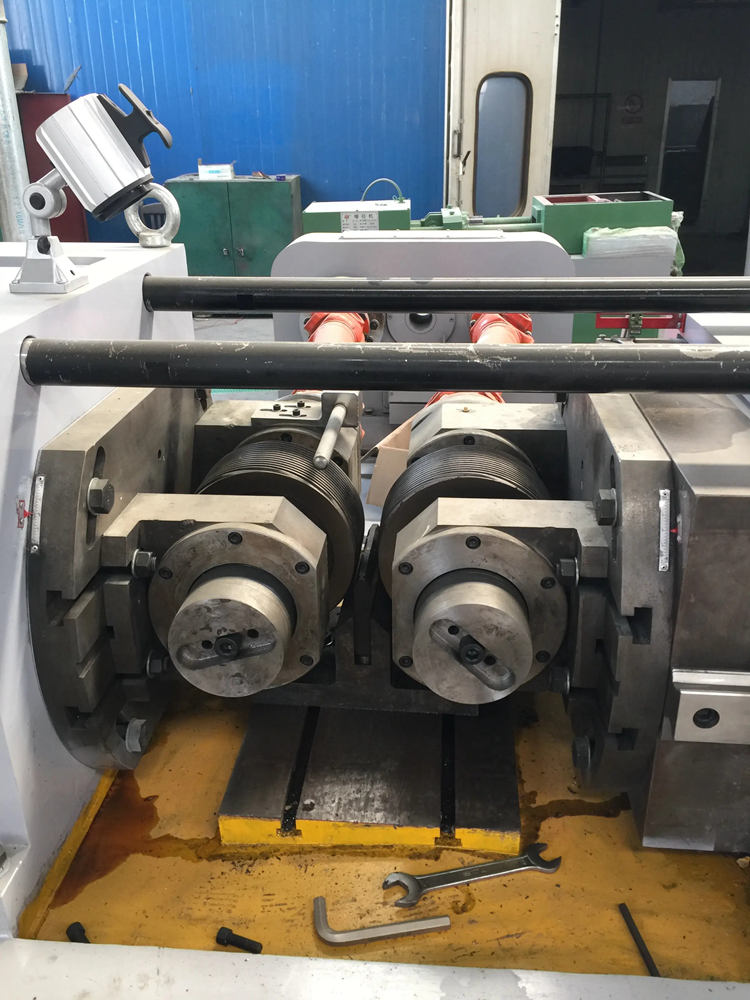

Understanding Elbow Forming Machines

Elbow forming machines are specialized equipment designed to create bends in pipes, which are essential for directing the flow of fluids. These machines can produce different types and sizes of elbows, catering to diverse industrial needs. The processes involved often include heating, bending, and sometimes even welding to ensure that the finished product meets stringent quality standards. Depending on the machine's capabilities, it can handle materials such as steel, stainless steel, and even certain alloys.

The Role of Manufacturers

Manufacturers of elbow forming machines are tasked with developing equipment that not only meets industry standards but also enhances efficiency and productivity. This includes the integration of advanced technologies such as Computer Numerical Control (CNC) systems, which enable precise control over the bending process. As technology evolves, manufacturers are continually finding ways to improve their machines' speed, accuracy, and versatility.

Trends in the Industry

One notable trend in the elbow forming machine manufacturing sector is the increasing focus on automation. As companies strive to streamline operations and reduce costs, automated systems are becoming more prevalent. Automation not only increases production speed but also minimizes human error, ultimately leading to higher quality products.

Moreover, sustainability is influencing the industry. Manufacturers are exploring eco-friendly materials and processes to align with global initiatives aimed at reducing environmental impact. This shift is beneficial for both manufacturers and customers, as it promotes responsible manufacturing while meeting growing consumer demand for sustainable products.

Leading Manufacturers

Among the prominent players in the elbow forming machine manufacturing industry, several stand out for their innovation and quality. Companies like Bending Technologies, Inc. and Baileigh Industrial have established reputations for producing reliable and efficient machinery. These manufacturers often offer a range of products that cater to different industry segments, from small workshops to large-scale industrial operations.

Additionally, many manufacturers are not limited to providing machinery. They often offer comprehensive support services, including training, maintenance, and spare parts supply. This holistic approach helps customers maximize the value of their investment in elbow forming machines.

Challenges Ahead

Despite the advancements, elbow forming machine manufacturers face several challenges. The increasing complexity of infrastructure projects requires more sophisticated equipment capable of handling various materials and designs. Additionally, supply chain disruptions and rising raw material costs can impact production timelines and pricing.

However, these challenges also present opportunities for manufacturers to innovate and adapt. Investing in research and development allows manufacturers to stay ahead of market demands and address the needs of their customers effectively.

Conclusion

In conclusion, elbow forming machine manufacturers are pivotal in advancing the manufacturing landscape. Their ability to innovate and adapt to changing market conditions is essential for meeting the growing demands of various industries. As we move forward, these manufacturers will continue to play a significant role in the development of high-quality piping solutions, ensuring that businesses can rely on efficient and sustainable products. With the right focus on technology and sustainability, the future of elbow forming machine manufacturing looks promising.