In the world of modern construction, the need for durable and cost-effective roofing solutions is greater than ever. Whether you are looking for a roof panel roll forming machine for sale, a sheet profile rolling machine, or an iron roof sheet making machine, having the right equipment is essential to ensuring quality and efficiency. These machines are pivotal in manufacturing roof panels and sheets that provide strength and durability for buildings, warehouses, and other infrastructures. Additionally, understanding the steel sheet making machine and the steel roof sheet making machine price is important for businesses to make informed decisions when investing in production equipment. This advertorial will explore the key features and benefits of these machines and help guide your purchasing decision.

Discover the Best Roof Panel Roll Forming Machine for Sale

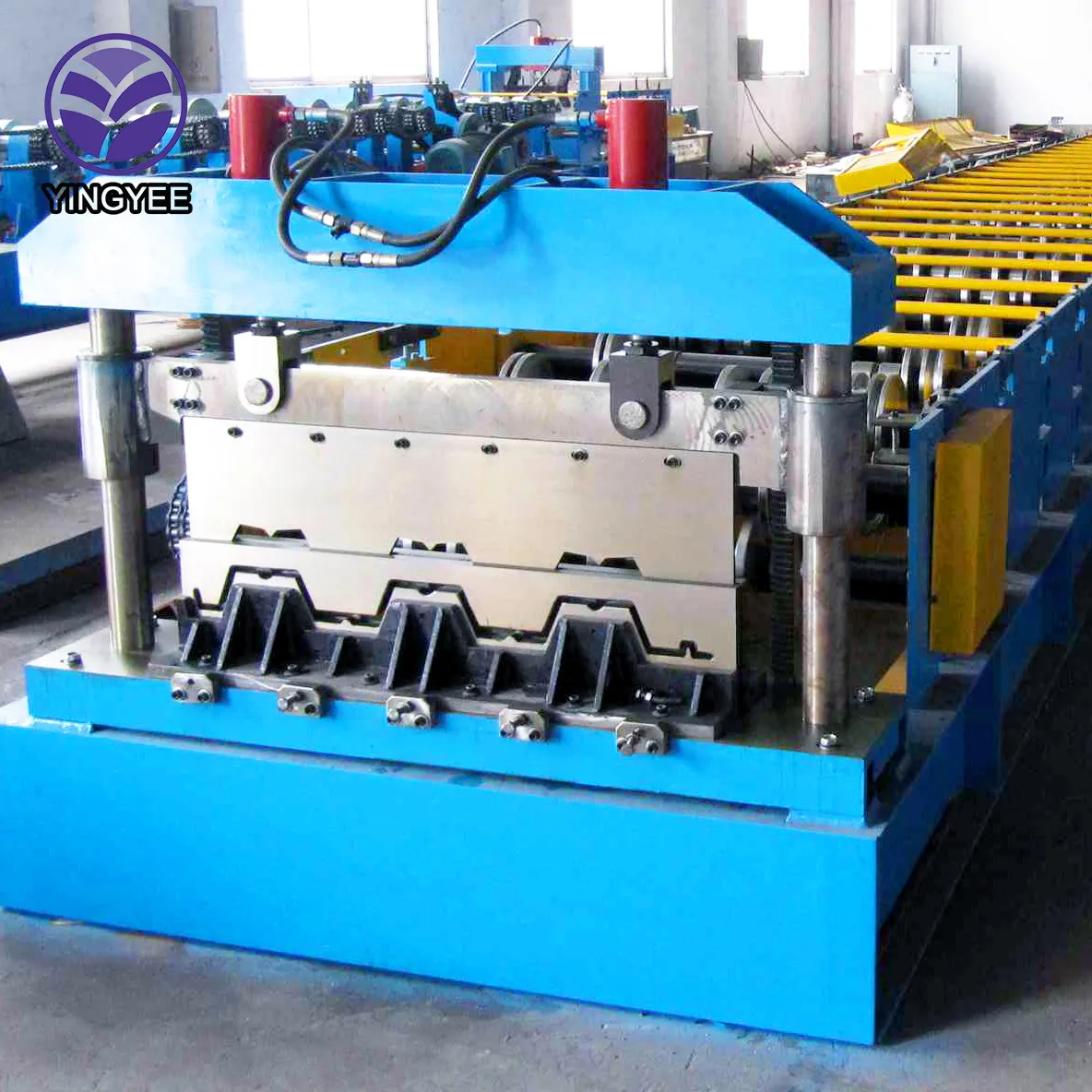

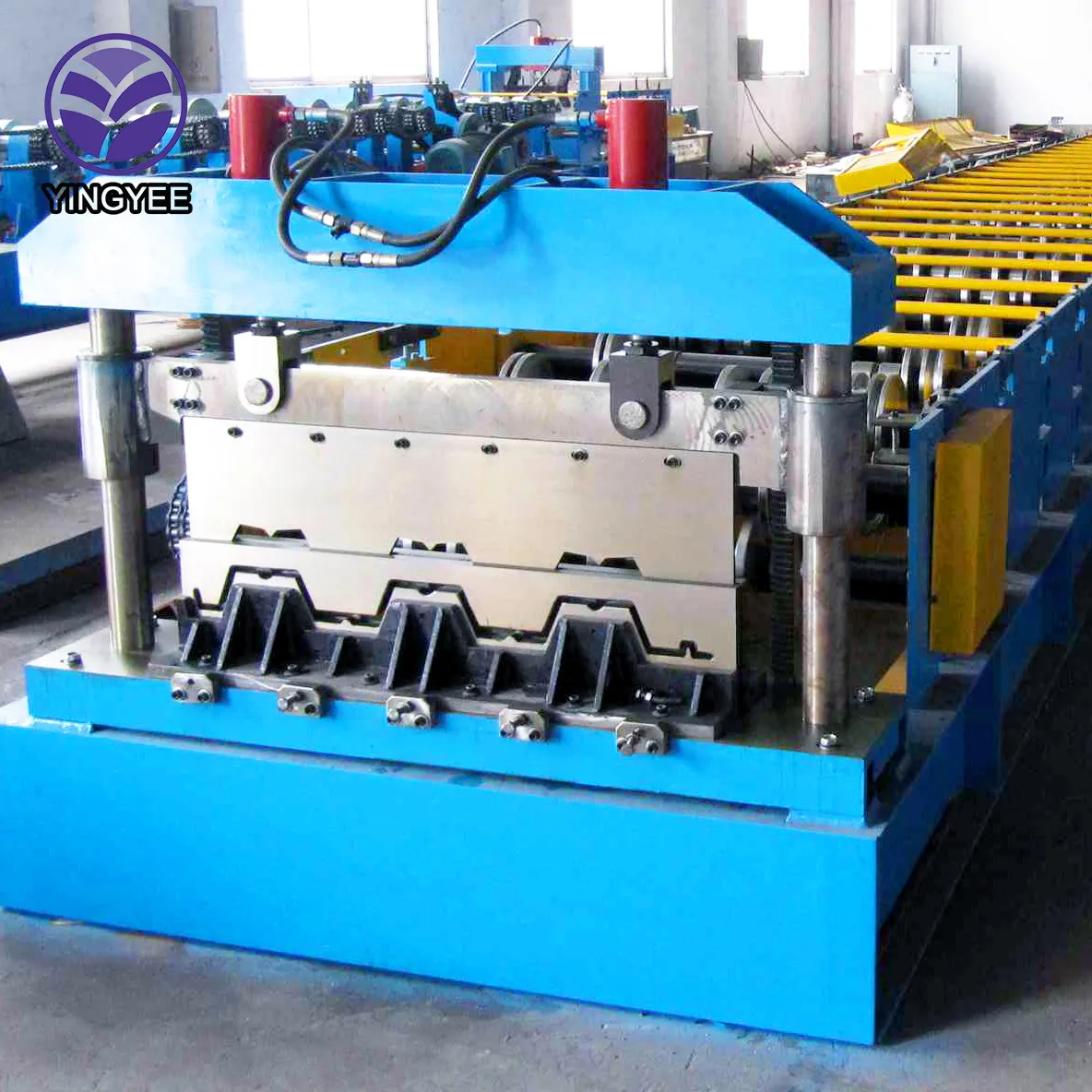

The roof panel roll forming machine for sale is one of the most sought-after machines in the roofing and construction industry. These machines are designed to manufacture high-quality roofing panels, which are used for both residential and commercial buildings. A roof panel roll forming machine for sale can produce various roofing profiles such as corrugated sheets, tile sheets, and trapezoidal sheets. The versatility and automation of these machines ensure fast production speeds and minimal waste, making them an essential investment for roofing manufacturers.

When purchasing a roof panel roll forming machine for sale, it’s important to consider factors such as production speed, material compatibility, and precision. Many roof panel roll forming machines for sale offer advanced features such as automatic length cutting, high-speed forming, and robust control systems, allowing manufacturers to produce high volumes of roof panels in less time and with greater consistency. This makes them an ideal choice for businesses looking to scale their production capacity while maintaining high standards of quality and reliability in their finished products.

Versatility of Sheet Profile Rolling Machines

A sheet profile rolling machine is a versatile piece of equipment that can be used to create a wide variety of sheet profiles for various applications, including roofing, cladding, and paneling. These machines are designed to take flat metal sheets and roll them into different shapes, such as corrugated sheets or trapezoidal profiles, depending on the needs of the project. With a sheet profile rolling machine, manufacturers can produce roofing sheets that are both strong and aesthetically appealing, which are crucial in both commercial and residential construction projects.

The sheet profile rolling machine is highly adaptable, allowing for the easy production of different sheet profiles without the need for complex adjustments or tooling changes. This makes it a valuable investment for companies that need to produce multiple sheet profiles quickly and efficiently. By using a sheet profile rolling machine, businesses can ensure that their production lines are capable of meeting the diverse needs of their customers, from lightweight roofing sheets to heavy-duty industrial panels.

Iron Roof Sheet Making Machines: High Durability and Efficiency

An iron roof sheet making machine is specifically designed to produce strong and durable roofing sheets made from iron. These machines are perfect for creating sheets used in both residential and industrial buildings, where long-lasting and weather-resistant roofs are a priority. The iron roof sheet making machine is built to handle the heavy-duty demands of roof sheet production, allowing manufacturers to create high-quality iron sheets that can withstand the elements for years.

The iron roof sheet making machine operates by feeding iron coils into the forming system, where they are shaped into the desired profile. This process ensures precision and uniformity, making it possible to produce large quantities of iron roofing sheets with minimal material waste. Furthermore, an iron roof sheet making machine can be equipped with additional features such as automatic cutting, punching, and bending, which increases the machine’s efficiency and versatility. With the ability to produce iron roof sheets at scale, this machine is a crucial investment for manufacturers looking to meet the growing demand for strong, reliable roofing solutions.

Understanding Steel Sheet Making Machines and Their Advantages

The steel sheet making machine is a highly effective tool for the production of steel sheets used in roofing, cladding, and other structural applications. These machines are designed to process coils of steel and convert them into sheets with precise thickness and shape. Steel sheet making machines offer various advantages, including the ability to create steel sheets in a range of profiles, high-speed production capabilities, and enhanced durability, making them ideal for large-scale manufacturing operations.

One of the key benefits of a steel sheet making machine is its ability to produce high-quality steel sheets that can be used for a variety of applications, from roofing panels to siding and insulation. Steel is known for its strength and longevity, making it a preferred material for construction projects. The steel sheet making machine enables manufacturers to produce sheets that meet the highest standards of quality and durability. Additionally, these machines are designed to be energy-efficient and require minimal maintenance, reducing operating costs and downtime for businesses in the long run.

Steel Roof Sheet Making Machine Price and Value

When considering purchasing a steel roof sheet making machine, understanding the steel roof sheet making machine price is essential for making an informed investment decision. Prices for these machines can vary based on factors such as machine capacity, automation features, and the specific profiles they can produce. Generally, the steel roof sheet making machine price will be influenced by the complexity of the machine and the materials it can handle.

However, it’s important to look beyond the initial steel roof sheet making machine price and consider the long-term value the machine can bring to your business. High-quality machines are designed to provide years of reliable service, produce high volumes of sheets, and require minimal maintenance, making them a worthwhile investment for businesses looking to scale their production. Additionally, when choosing a steel roof sheet making machine, it’s essential to factor in the potential savings in energy, labor, and material costs that can result from efficient, high-performance equipment. In many cases, investing in a more advanced machine may result in significant cost savings and higher profit margins in the long run.

In conclusion, whether you are searching for a roof panel roll forming machine for sale, a sheet profile rolling machine, or an iron roof sheet making machine, having the right equipment is crucial for meeting the needs of the modern construction industry. Understanding the capabilities and prices of these machines will help you make an informed decision, ensuring that your production processes are efficient, cost-effective, and high-quality. By investing in top-of-the-line steel sheet making machines, manufacturers can ensure that their roofing sheets meet the highest standards of durability and performance, while also improving production efficiency and reducing operational costs.