The Round Pipe Roll Forming Machine A Comprehensive Overview

In the manufacturing industry, efficiency and precision are paramount. One of the machines that significantly contributes to this is the round pipe roll forming machine. This advanced technology plays a pivotal role in the production of round pipes, which are widely used in various applications, including construction, automotive, and infrastructure. In this article, we will explore the functionality, benefits, and applications of round pipe roll forming machines.

Understanding Round Pipe Roll Forming Machines

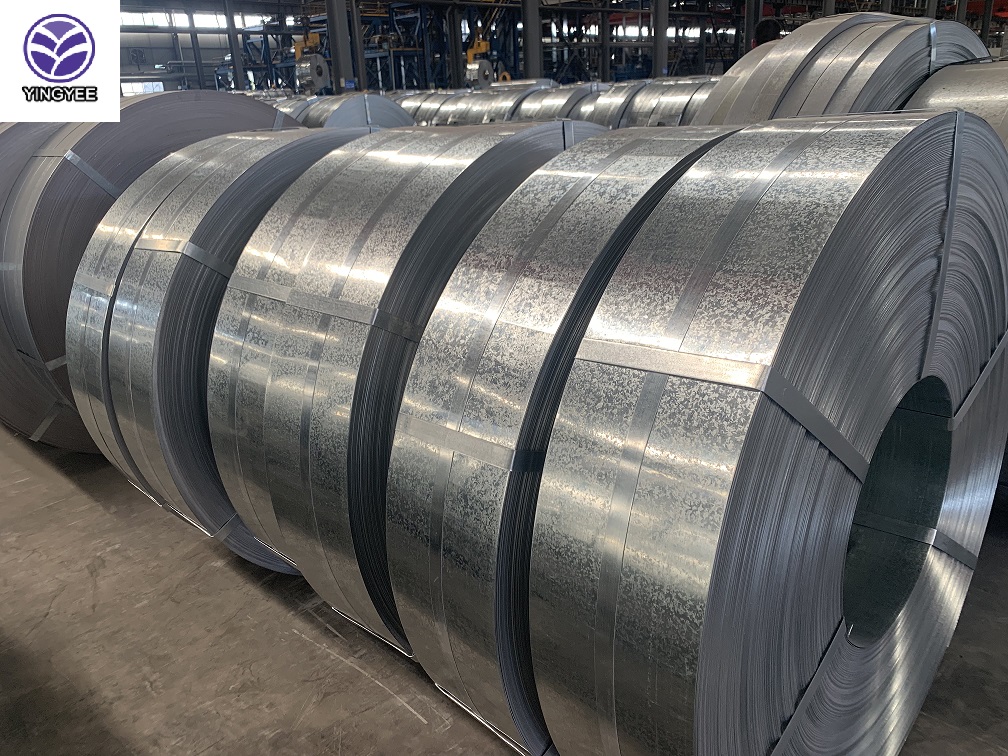

A round pipe roll forming machine is designed to create round pipes from metal sheets or coils. The process involves feeding a flat sheet of metal through a series of rollers that shape the material into a round profile. Each roller gradually bends and forms the strip, eventually shaping it into the final round pipe dimension. The machines are equipped with multiple stations that perform different rolling tasks, ensuring uniformity and precision throughout the process.

Key Features and Functionality

1. Adjustable Rollers One of the standout features of round pipe roll forming machines is the ability to adjust the rollers to produce different diameters and wall thicknesses. This versatility allows manufacturers to cater to various requirements in a single production run.

2. High Efficiency These machines operate at high speeds, significantly increasing production rates. The efficient design and automation reduce downtime, allowing for continuous operation and maximized output.

3. Precision Engineering Modern round pipe roll forming machines are equipped with advanced technology such as CNC (Computer Numerical Control) systems, which ensure precise control over the shaping process. This results in less material waste and higher quality products.

4. Durable Construction Built with robust materials, these machines are designed for longevity and can withstand the rigors of industrial environments. This durability translates to a lower total cost of ownership for manufacturers.

Benefits of Using Round Pipe Roll Forming Machines

- Cost-Effectiveness Investing in a roll forming machine can lead to significant cost savings over time

. The automation and reduced labor requirements lower operational costs, while the efficient use of materials minimizes waste.- Customization Capabilities With the ability to adjust settings and specifications, manufacturers can easily produce customized round pipes to meet specific project requirements. This adaptability is vital in industries where specifications frequently change.

- Quality Assurance The consistency of the product quality is enhanced through the automated processes of roll forming. This is particularly important in sectors such as automotive and construction, where material integrity is non-negotiable.

Applications of Round Pipes

Round pipes are essential in several industries

- Construction Used for structural applications, such as columns and beams, round pipes provide strength and stability.

- Automotive Employed in the manufacturing of exhaust systems, roll cages, and chassis, round pipes are integral to vehicle safety and performance.

- Furniture Round pipes are often used in furniture design, offering aesthetic appeal and robust support for tables, chairs, and other fixtures.

Conclusion

In conclusion, the round pipe roll forming machine plays a critical role in modern manufacturing. Its ability to produce high-quality, customized round pipes efficiently makes it an invaluable asset across various industries. As technology continues to advance, these machines are likely to become even more sophisticated, offering manufacturers enhanced capabilities that meet the demands of an increasingly dynamic marketplace. Investing in a round pipe roll forming machine can set the foundation for innovation and growth, highlighting the machine's importance in the future of manufacturing.