Standing Seam Roof Machine A Key to Modern Roofing Solutions

In the world of construction and architecture, the choice of roofing materials and systems plays a significant role in the overall performance, aesthetics, and longevity of a building. Among various roofing options, standing seam roofs have gained immense popularity due to their durability, energy efficiency, and modern appearance. A crucial component in the installation of such roofs is the use of advanced standing seam roof machines, which streamline the manufacturing process, ensuring high-quality results.

What is a Standing Seam Roof?

Standing seam roofs consist of vertical panels that are joined together at raised seams. This design provides several advantages, including excellent waterproofing, ease of installation, and minimal maintenance. Furthermore, standing seam metal roofs are highly resistant to extreme weather conditions, making them ideal for various climates. The continuous nature of the seams also promotes a sleek, modern aesthetic that appeals to many architects and homeowners.

The Role of Standing Seam Roof Machines

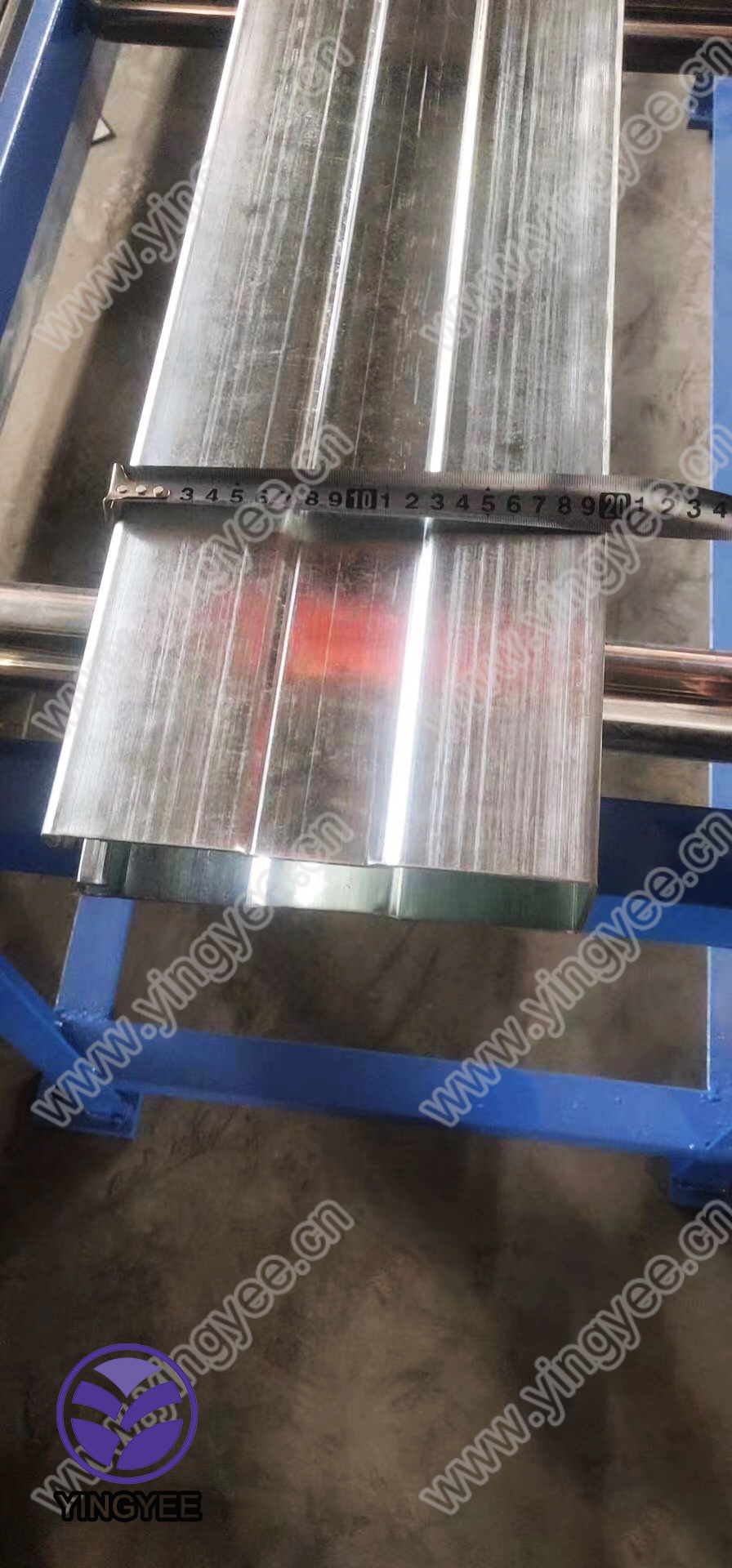

Standing seam roof machines are specialized equipment designed to create the metal panels used in roofing systems. These machines can produce panels of various widths and lengths, tailored to the specific requirements of a project. They operate through a combination of forming, cutting, and folding processes that transform flat metal sheets into functional roofing panels with raised seams.

One of the standout features of standing seam roof machines is their ability to produce panels on-site. This capability significantly reduces waste and ensures that the panels fit perfectly to the dimensions of the roof. Moreover, on-site production eliminates transportation issues and delays, enabling contractors to maintain project timelines efficiently.

Advancements in Technology

Technological advancements have revolutionized the production capabilities of standing seam roof machines. Modern machines are equipped with computer-controlled systems that enhance precision and reduce manual labor. These innovations allow for the automated adjustment of panel specifications, ensuring consistent quality across all units produced.

Additionally, many machines now offer the ability to integrate insulation and other materials directly into the panel during the manufacturing process. This integration not only improves the thermal performance of the roofing system but also contributes to energy efficiency, aligning with the growing demand for sustainable building practices.

Benefits of Using Standing Seam Roof Machines

The benefits of utilizing standing seam roof machines are manifold. Firstly, they significantly reduce the time required for production and installation, allowing contractors to take on more projects and meet tight deadlines. Secondly, the precision of the panels produced ensures a perfect fit, which is critical for the effectiveness of the roofing system and its longevity.

Furthermore, standing seam roofs created with these machines require less maintenance compared to traditional roofing systems. The high-quality materials used, combined with the precision manufacturing process, reduce the likelihood of leaks and other issues over time.

Conclusion

As the construction industry continues to evolve, standing seam roof machines stand out as a vital tool for modern roofing solutions. Their ability to produce high-quality, customized panels on-site contributes to greater efficiency, reduced waste, and improved overall performance of roofing systems. With a focus on sustainability and durability, standing seam roofs will likely remain a favored choice for architects and builders alike for years to come. Investing in standing seam roof technology not only enhances the quality of roofing installations but also supports the broader goals of environmental sustainability in the construction industry.