Z-Shape Purlin Roll Forming Machinery A Comprehensive Overview

In the modern construction industry, efficiency, durability, and cost-effectiveness are paramount. One innovative solution that has gained traction is Z-shape purlin roll forming machinery. This technology not only improves structural integrity but also streamlines manufacturing processes, making it a popular choice among construction professionals and manufacturers alike.

What are Z-Shape Purlins?

Z-shape purlins are structural components predominantly used in the construction of buildings. Characterized by their 'Z' profile, these purlins serve as horizontal supports for roofs or walls in both residential and commercial structures. Their design allows for effective load distribution and minimizes deflection, making them an ideal choice for a range of applications, from agricultural buildings to large-scale industrial complexes.

The Role of Roll Forming Machinery

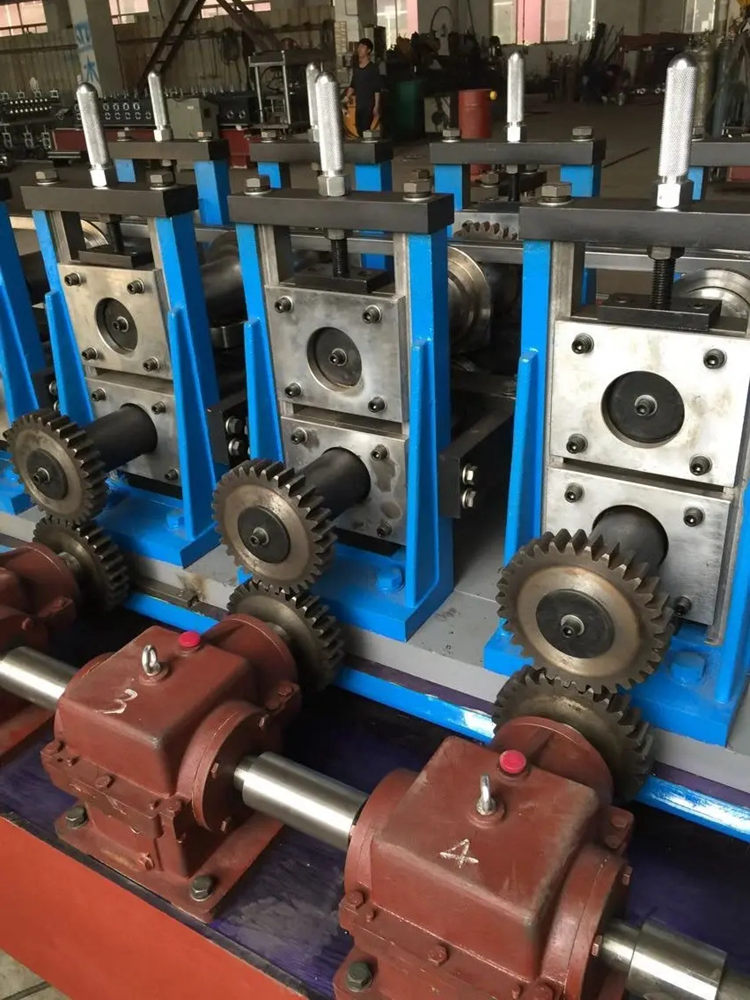

Roll forming machinery plays a critical role in the production of Z-shape purlins. This process involves feeding a metal strip into a series of rollers that gradually shape the strip into the desired Z-profile. The roll forming process is advantageous due to its high efficiency, producing long lengths of purlins without the need for extensive machining. Additionally, the precision of the machinery ensures consistent quality and accuracy, reducing waste and enhancing overall productivity.

Features of Z-Shape Purlin Roll Forming Machinery

Modern Z-shape purlin roll forming machines come equipped with various advanced features aimed at optimizing performance. Key characteristics include

1. Automated Control Systems Many machines use computerized controls to manage the forming process. This automation allows for precise adjustments in real-time, ensuring quality output and reducing the potential for human error.

3. High Production Speed The efficiency of roll forming allows for rapid production rates. Depending on the specific system, manufacturers can produce significant lengths of purlins in a matter of minutes.

4. Material Compatibility These machines can work with a variety of materials, including galvanized steel, aluminum, and even stainless steel, which broadens their application across different construction projects.

5. Easy Maintenance The design of contemporary roll forming machinery emphasizes ease of maintenance and operation. This minimizes production interruptions and maximizes uptime.

Advantages of Using Z-Shape Purlin Roll Forming Machinery

1. Cost Efficiency By automating the manufacturing process, companies can significantly reduce labor costs and minimize material waste, ultimately leading to lower production costs.

2. Enhanced Strength and Durability The continuous length of purlins produced through roll forming enhances their structural integrity, offering better load-bearing capabilities compared to traditional cut-and-weld methods.

3. Customization Options Z-shape purlins can be tailored to specific project requirements, including custom sizes and thicknesses, making them versatile for a wide range of applications.

4. Quick Turnaround The rapid production capabilities of roll forming machinery lead to shorter lead times, allowing businesses to meet tight project deadlines effectively.

Conclusion

Z-shape purlin roll forming machinery represents a significant advancement in the production of vital structural components in construction. By combining speed, efficiency, and versatility, this technology contributes to the development of resilient and cost-effective building solutions. As the construction industry continues to evolve, adopting such innovative manufacturing methods is essential for companies seeking to remain competitive and meet the growing demands for high-quality structures.