The Revolution of Solar Mounting Brackets through Roll Forming Technology

In the quest for sustainable energy solutions, solar power has emerged as one of the most promising alternatives to fossil fuels. Integral to the effectiveness of solar energy systems are the mounting brackets that secure solar panels to buildings and other structures. This article discusses the evolution and benefits of solar mounting brackets produced through roll forming technology, highlighting their significance in the renewable energy landscape.

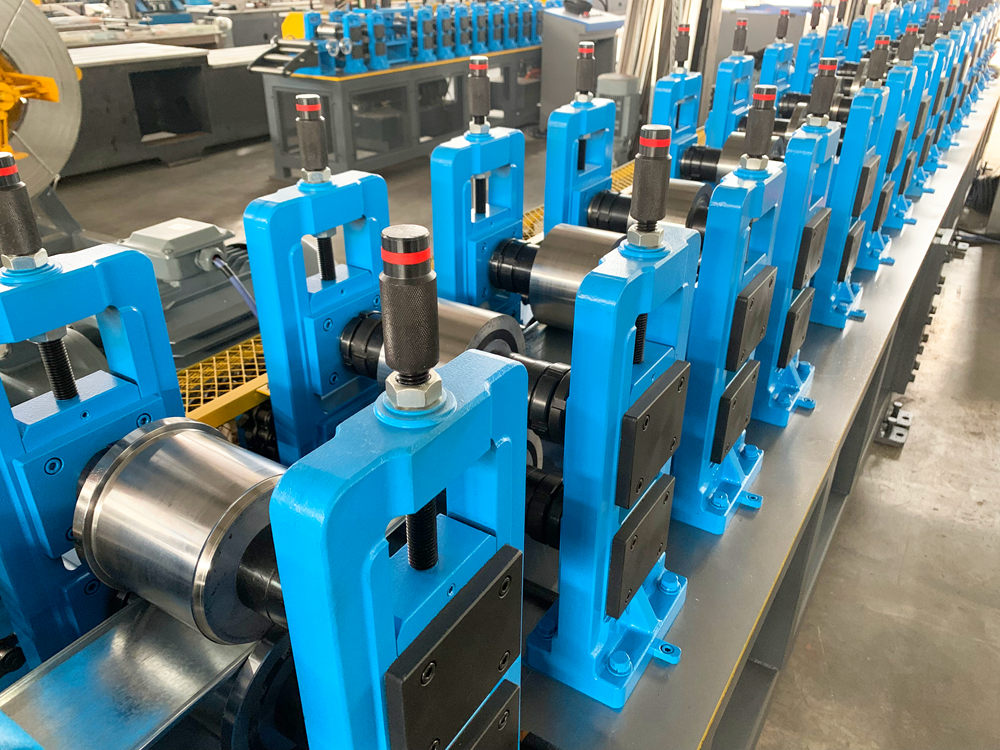

Understanding Roll Forming

Roll forming is a metal forming process that involves continuously feeding a strip of metal through a series of rollers. These rollers shape the metal into desired profiles without cutting or removing material. The technique offers significant advantages, including high production speed, minimal material waste, and the ability to create complex shapes that are consistent in quality.

In the context of solar mounting brackets, roll forming is particularly suited because these components require both strength and durability to withstand environmental stresses such as wind, snow, and temperature variations. The process enables manufacturers to produce brackets that are not only robust but also lightweight, which can lower transportation costs and ease installation.

Advantages of Roll Formed Solar Mounting Brackets

1. Cost Efficiency Roll forming is known for its efficiency in production. The ability to produce long sections of brackets in a single pass reduces manufacturing time and labor costs, which translates to savings for consumers. Additionally, the minimized waste produced during the roll forming process contributes to lower material costs.

2. Structural Integrity The continuous nature of roll forming produces a stronger product by maintaining the uniform grain structure of the metal. This quality is crucial for solar mounting brackets, which must endure various loads and forces. As a result, roll-formed brackets tend to have higher tensile strength and can support solar panels securely in diverse conditions.

3. Customization The flexibility of roll forming allows for customization of solar mounting brackets to meet specific project requirements. Manufacturers can adapt designs to accommodate different panel sizes, orientations, and mounting locations. This customization not only optimizes the efficiency of solar installations but also maximizes the energy output of solar panels.

4. Durability and Corrosion Resistance Solar mounting brackets are typically exposed to outdoor conditions, making durability an essential factor. Roll forming can be combined with other processes such as galvanization or powder coating to enhance the corrosion resistance and extend the lifespan of the brackets. This ensures that they maintain their structural integrity and appearance over time.

5. Sustainability As the world moves towards greener technologies, the use of roll forming for solar mounting brackets aligns with sustainability goals. The efficient manufacturing process, reduction in material waste, and the long service life of the products contribute to a lower carbon footprint over the lifespan of solar energy systems. Additionally, many of the materials used in roll forming are recyclable, further enhancing its eco-friendly qualities.

Conclusion

The integration of roll forming technology in the production of solar mounting brackets is a significant innovation that supports the growth of the solar energy sector. By providing cost-effective, durable, and customizable solutions, roll-formed brackets play a vital role in maximizing the efficiency and reliability of solar installations. As the demand for renewable energy sources continues to rise, the advancements in manufacturing processes like roll forming will undoubtedly propel the solar industry towards a more sustainable future. With this technology, we not only enhance the viability of solar power but also contribute to the broader goals of environmental conservation and energy innovation.