The Metal Strut Channel Roll Forming Machine Revolutionizing Construction and Manufacturing

In the dynamic world of construction and manufacturing, efficiency and precision are paramount. The metal strut channel roll forming machine stands out as a vital piece of machinery that significantly enhances the production of strut channels, widely used in various structural applications. This article explores the functions, benefits, and applications of these innovative machines, highlighting their impact on the industry.

Understanding Metal Strut Channels

Metal strut channels are U-shaped profiles made from steel or other metals, designed to provide support and framing in construction projects. They play a crucial role in creating infrastructures such as shelving, electrical support systems, and HVAC installations. The demand for these strut channels continues to rise as industries look for versatile, strong, and lightweight options to support their structures.

The Role of Roll Forming Technology

Roll forming is a sophisticated manufacturing process where strips of metal are fed through a series of rollers to achieve the desired profile. The metal strut channel roll forming machine automates this process, making it quicker and more cost-effective. By utilizing continuous sheet metal, roll forming minimizes waste and allows for the production of long lengths of struts that can be cut to specified dimensions.

Key Components of a Roll Forming Machine

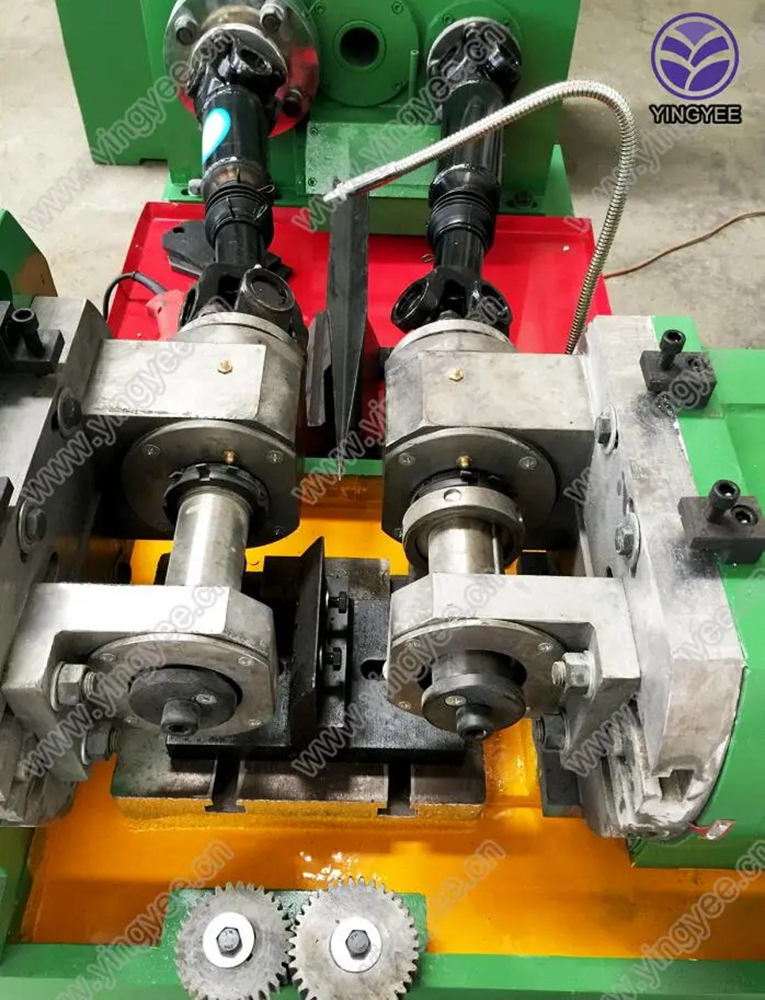

A typical metal strut channel roll forming machine consists of several key components

1. Uncoiler This unit holds the steel coil and unwinds it for processing. 2. Roll forming stations These are a series of configurable rollers that shape the metal into the desired profile sequentially. 3. Cut-off system This element ensures that the metal channels are cut to precise lengths after the roll forming process. 4. Control system Modern machines feature advanced software that allows operators to program specifications and monitor production in real-time.

Benefits of Metal Strut Channel Roll Forming Machines

1. Efficiency These machines operate continuously, producing large quantities of strut channels in a short time. This efficiency can significantly reduce labor costs and lead times in construction projects.

2. Precision Roll forming produces highly accurate profiles with tight tolerances, ensuring that each strut channel meets industry standards.

3. Flexibility Many modern machines can be easily adjusted for various channel sizes and shapes, allowing manufacturers to cater to diverse customer needs without extensive downtime.

4. Material Savings The roll forming process results in minimal waste, making it an environmentally friendly manufacturing option.

5. Durability The strut channels produced are robust and long-lasting, essential for supporting heavy loads and ensuring safety in construction applications.

Applications Across Industries

The versatility of metal strut channels makes them applicable in numerous sectors. In the construction industry, they are used for framing, support systems, and securing plumbing and electrical components. In manufacturing, strut channels can serve as racking systems, conveyor supports, and machinery frameworks. Their widespread use underscores the importance of efficient production methods, such as those enabled by roll forming technology.

Conclusion

The metal strut channel roll forming machine represents a significant advancement in manufacturing technology, offering benefits that enhance production efficiency, precision, and material utilization. As industries continue to evolve and demand high-quality components, the role of these machines will only grow, contributing to the construction and manufacturing sectors' future. Embracing such innovative solutions is vital for companies looking to thrive in an increasingly competitive landscape.