Hydraulic Guillotine Shearing Machine A Cutting-Edge Tool for Precision Metal Shearing

In the world of metal fabrication, precision and efficiency are paramount. Among the plethora of machinery designed to meet these demands, the hydraulic guillotine shearing machine stands out as a key player in the industry. This advanced machine offers unparalleled cutting capabilities, making it an essential asset for both small workshops and large manufacturing facilities.

What is a Hydraulic Guillotine Shearing Machine?

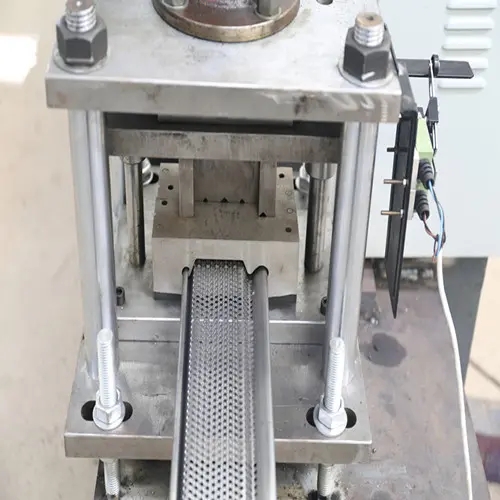

A hydraulic guillotine shearing machine is a specialized tool used to cut sheet metal into various sizes and shapes. Utilizing hydraulic mechanisms, this machine applies immense force to shear through the metal, producing clean and precise cuts. The design of the guillotine shearing machine features a fixed blade and a moving blade that operates like a guillotine, hence the name. The hydraulic system enables smooth operation, reducing the physical strain on operators and increasing the effectiveness of the cut.

The Mechanism Behind the Machine

The core advantage of a hydraulic guillotine shearing machine lies in its hydraulic system. This system consists of a pump that generates hydraulic fluid pressure, directing it to the shearing blades. When activated, the hydraulic pressure pushes the moving blade downward with remarkable force, allowing it to slice through the material effortlessly. The machine can handle a diverse range of metals, including mild steel, stainless steel, aluminum, and copper, with thicknesses that can vary from a few millimeters to several centimeters.

The accuracy of the machine is complemented by adjustable backgauge mechanisms that help in setting the desired length of the cut piece. Operators can easily program these settings, ensuring repeatability and minimizing material waste. Many modern guillotine shearing machines also integrate digital displays and controls for enhanced precision.

Advantages of Hydraulic Guillotine Shearing Machines

1. Precision Cutting One of the most significant benefits of hydraulic guillotine shearing machines is their ability to make precise cuts. The hydraulic mechanism allows for consistent pressure throughout the cutting process, which translates into clean edges and minimal deformation of the material.

2. Versatile Applications These machines are not limited to fabricating specific types of metal. Their versatility allows them to cut various materials and thicknesses, making them indispensable in industries such as automotive, aerospace, and construction.

3. Increased Efficiency Hydraulic guillotine shearing machines operate faster than their mechanical counterparts, significantly increasing production rates. As a result, businesses can meet high demand without compromising quality.

4. Operator Safety The design of hydraulic machines tends to incorporate safety features that protect operators from accidents. The enclosed structure and advanced control systems limit the risk of mishaps during operation.

5. Reduced Wear and Tear The hydraulic mechanism reduces repetitive stress on mechanical parts, leading to lower maintenance requirements and extended machine life.

Conclusion

The hydraulic guillotine shearing machine is an essential tool in modern metal fabrication. Its ability to deliver precision, efficiency, and safety makes it a favorite among manufacturers. As technology continues to advance, we can expect even more innovations in hydraulic shearing machines, providing enhanced features that will further improve productivity and operational capabilities. Investing in a hydraulic guillotine shearing machine is not just about acquiring a piece of equipment; it is about equipping oneself for a future where precision and efficiency in metal fabrication are critical to success.