The Advancements and Benefits of Drywall Stud Machines

In the ever-evolving field of construction and interior design, efficiency, precision, and innovation are paramount. One of the significant advancements that have made a difference in drywall installation is the introduction of drywall stud machines. These machines have revolutionized the way drywall is handled, enabling faster, more accurate installations while reducing labor costs.

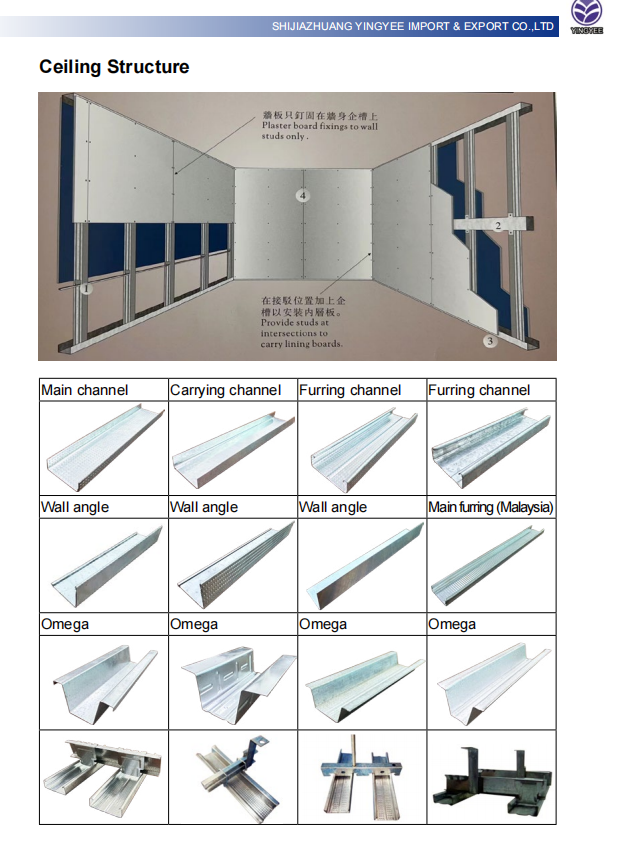

Understanding Drywall Stud Machines

Drywall stud machines, often referred to as framing machines, are specialized equipment designed to automate the process of creating metal or wooden frames for drywall installation. These machines can cut, drill, and assemble studs tailored to specific project requirements. Equipped with advanced technology, they enhance productivity by significantly reducing manual labor and the potential for human error.

Increased Efficiency

One of the primary benefits of drywall stud machines is their ability to streamline the framing process. Traditional methods require significant manpower, involve intricate measurements, and are susceptible to errors. Drywall stud machines perform these tasks with remarkable speed and precision. On average, a skilled team may take hours to frame a room manually, while a stud machine can complete the same job in a fraction of the time. This increase in efficiency translates to fewer labor hours, allowing construction companies to allocate resources to other essential areas of the project.

Precision and Consistency

Another advantage of using drywall stud machines is the precision they provide

. These machines are designed to cut studs to exact specifications, ensuring that each piece fits perfectly into the intended space. This precision minimizes the risk of gaps or misalignments that can occur with manual installation. Moreover, the consistency achieved across multiple installations is particularly beneficial for large-scale projects, where uniformity is crucial for aesthetics and structural integrity. A well-framed wall not only looks better but also performs better, as it can support the drywall more effectively.

Versatility in Design

Drywall stud machines are versatile and adaptable, capable of handling various materials such as steel and wood. This versatility allows builders and contractors to choose the best materials for their specific designs and budgets. Additionally, these machines can accommodate different wall thicknesses and styles, making them suitable for a wide range of projects, from residential homes to commercial buildings.

Reducing Labor Costs

Labor costs constitute a significant portion of construction expenses. By utilizing drywall stud machines, companies can not only reduce the number of workers needed for framing but can also decrease the associated training time for new employees. Automated machines often require only one or two operators, leading to significant savings in labor costs over time. This reduction in workforce also minimizes the risk of workplace injuries associated with manual framing processes.

Environmental Impact

The use of drywall stud machines can also contribute to more sustainable building practices. With their precision cutting and assembly capabilities, these machines generate less waste compared to traditional manual methods. Reducing material waste not only helps in minimizing environmental impact but also contributes to cost savings for builders. Furthermore, as sustainability becomes more critical in the construction industry, using efficient technology aligns with eco-friendly practices.

Conclusion

Drywall stud machines represent a remarkable advancement in construction technology, offering benefits that include increased efficiency, precision, versatility, and reduced labor costs. As the industry continues to embrace automation and innovative solutions, drywall stud machines are set to play a vital role in transforming how drywall is installed. For contractors and builders looking to improve their processes and deliver high-quality results, investing in a drywall stud machine could prove to be a game-changer, paving the way for a more efficient and sustainable future in construction.