The Importance of Aluminum Roofing Sheet Making Machines

Aluminum roofing sheets have become increasingly popular in recent years due to their durability, lightweight properties, and aesthetic appeal. These sheets are widely used in various construction projects, from residential houses to commercial buildings. The process of manufacturing aluminum roofing sheets requires specialized machinery known as aluminum roofing sheet making machines. This article explores the significance of these machines, their working mechanisms, and their impact on the construction industry.

Understanding Aluminum Roofing Sheets

Aluminum roofing sheets are made from aluminum alloy, which makes them resistant to the elements, such as rain, snow, and corrosion. Unlike traditional roofing materials like asphalt or wood, aluminum sheets do not warp, crack, or rot, making them an ideal choice for long-term investments. Furthermore, they are lightweight, making them easier and more economical to transport and install. Their reflective properties help in energy conservation, as they can keep buildings cooler in hot climates.

The Role of Roofing Sheet Making Machines

The production of aluminum roofing sheets involves various stages, including cutting, forming, and finishing. Aluminum roofing sheet making machines are designed to automate and streamline these processes. These machines include features such as

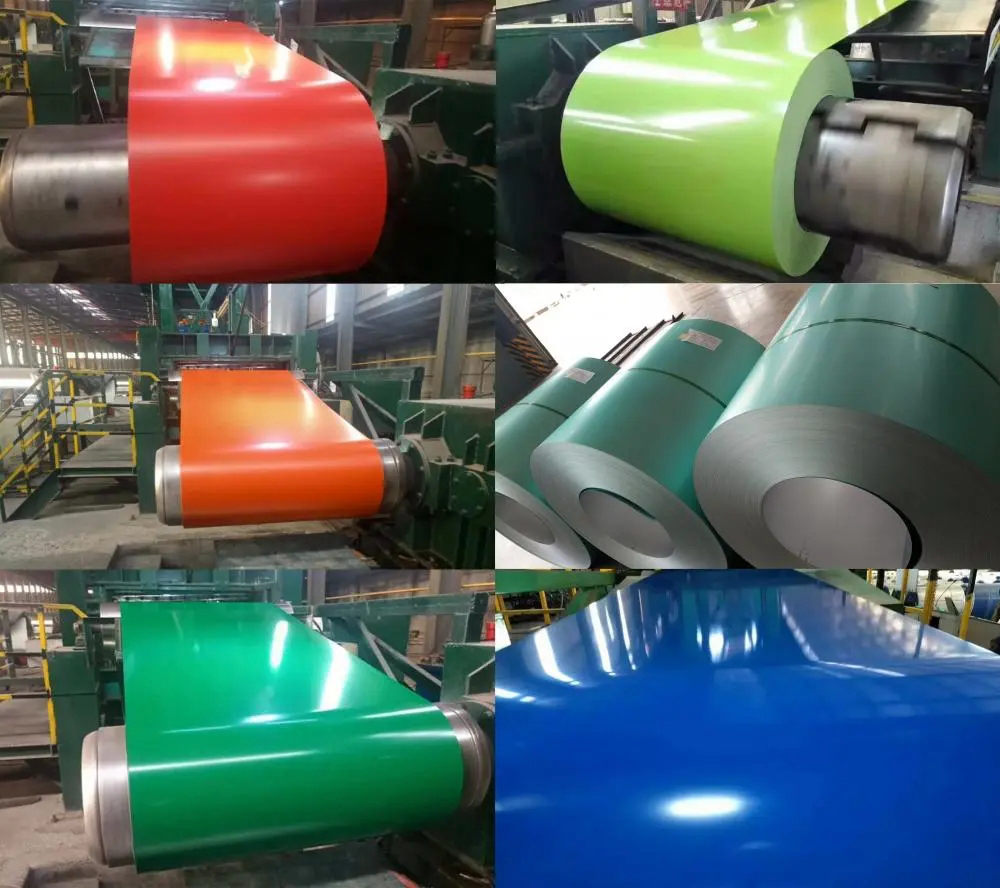

1. Coil Feeding The manufacturing process begins with an aluminum coil, which the machine feeds into the production line. This coil is unwound and guided through several rollers.

2. Roll Forming The heart of an aluminum roofing sheet making machine is its roll forming section. This section consists of several rollers that shape the flat aluminum sheets into the desired profile, such as ribbed or corrugated designs. Roll forming ensures a uniform thickness and shape, enhancing the aesthetic and functional qualities of the roofing sheets.

3. Cutting Mechanism Once the sheets are formed, they need to be cut to the required lengths. Most modern machines come equipped with automated cutting systems that provide precision and efficiency, reducing waste and ensuring high-quality output.

4. Finishing Touches After cutting, the sheets may go through additional processes such as surface treatment, painting, or coating. These finishing touches improve the appearance and increase the longevity of the roofing sheets.

Benefits of Using Aluminum Roofing Sheet Making Machines

Investing in aluminum roofing sheet making machines provides numerous benefits for manufacturers in the construction industry. Firstly, these machines significantly increase production efficiency, allowing companies to meet high demand while maintaining consistent quality. Additionally, automation minimizes labor costs, reducing the overhead expenses associated with manual production processes.

Secondly, the use of advanced machinery enhances the precision of manufacturing. High-quality roofing sheets not only fulfill aesthetic preferences but also meet industry standards for durability and safety. By ensuring accuracy in dimensions and properties, these machines help manufacturers build a solid reputation in the market.

Lastly, environmentally conscious practices are becoming increasingly important in the construction industry. Aluminum is a recyclable material, and using roofing sheet making machines promotes efficient use of resources. Manufacturers can recycle aluminum waste generated during production, contributing to sustainability efforts.

Conclusion

In summary, aluminum roofing sheet making machines play a vital role in the manufacturing sector of the construction industry. They enhance efficiency, reduce costs, and ensure the production of high-quality aluminum roofing sheets. As the demand for durable and environmentally friendly building materials continues to rise, investing in advanced machinery becomes essential for manufacturers looking to thrive in a competitive market. The evolution of these machines marks a significant step toward better construction practices, paving the way for a sustainable and innovative future in roofing solutions.