The Edge Channel Roll Forming Machine Achieving Superior Forming Effects

Roll forming is a highly efficient manufacturing process widely used in the production of various metal components. Among the different technologies within the roll forming sector, the edge channel roll forming machine stands out due to its ability to produce high-quality profiles with excellent precision and forming effects. This article explores the features, benefits, and applications of edge channel roll forming machines and how they contribute to improved manufacturing efficiency.

Understanding Roll Forming

Before delving into the specifics of the edge channel roll forming machine, it is essential to grasp the roll forming process itself. Roll forming involves feeding a continuous strip of metal through a series of rolls, which gradually shape the metal into the desired profile. The process is known for its ability to create consistent and complex shapes with high accuracy, making it a popular choice for manufacturers across various industries.

What is an Edge Channel Roll Forming Machine?

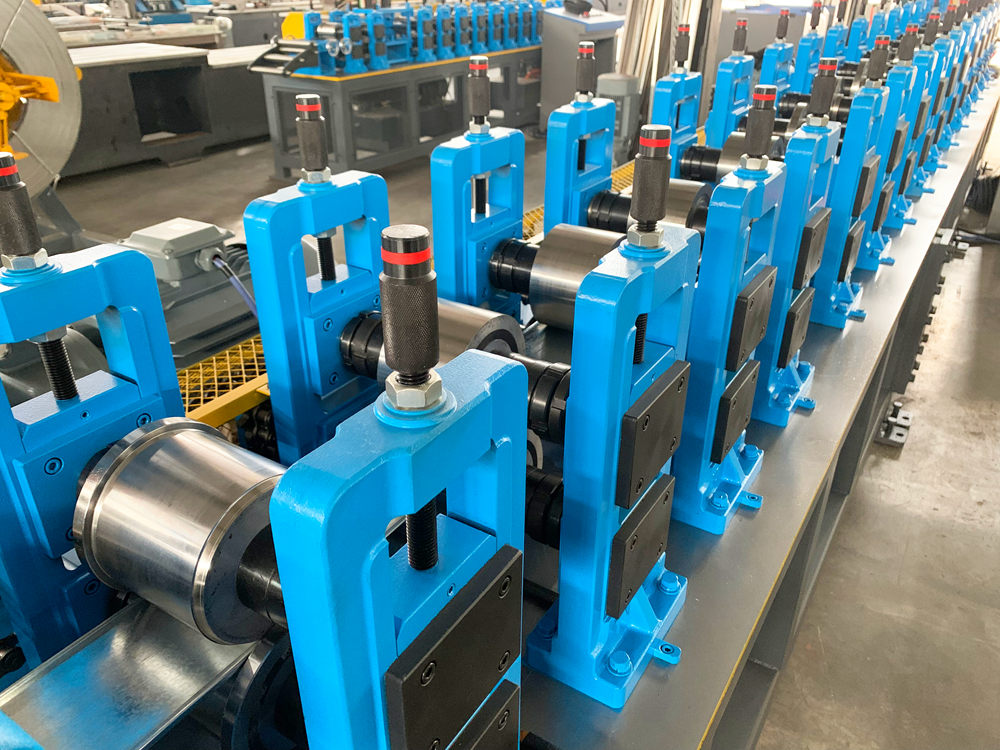

An edge channel roll forming machine is specifically designed to produce edge channels—long, thin strips of metal that feature a channel or groove along their length. These channels are crucial in numerous applications, such as in structural components, framing systems, automotive manufacturing, and even in the production of electronic enclosures.

The design of the edge channel roll forming machine includes multiple sets of rollers that progressively shape the metal strip. Each set of rollers is meticulously engineered to achieve the desired dimensions and forming effects while minimizing defects and ensuring uniformity in the final product.

Key Features and Benefits

1. High Precision One of the defining features of edge channel roll forming machines is their ability to achieve high levels of precision. The rollers are designed with meticulous attention to detail, allowing manufacturers to produce components that meet stringent tolerances. This precision is particularly important in applications where components must fit together seamlessly.

2. Efficiency The roll forming process is inherently efficient. Edge channel roll forming machines can operate at high speeds, often producing long lengths of channel in a relatively short amount of time. This capability leads to increased productivity and reduced lead times for manufacturers, allowing them to meet demand without compromising quality.

3. Versatility Edge channel roll forming machines can accommodate a variety of materials, including different types of steel, aluminum, and other metals. Additionally, the machines can be configured to produce different channel sizes and shapes, enabling manufacturers to diversify their product offerings without investing in multiple machines.

4. Reduced Waste The roll forming process generates minimal waste, as the metal strip is continuously formed without significant cutting or scrap. This not only lowers material costs but also aligns with sustainability initiatives in manufacturing.

5. Improved Forming Effects The design and operation of edge channel roll forming machines ensure that the formed channels have strong structural integrity and aesthetic appeal. The ability to achieve smooth edges and precise angles contributes to the overall quality of the final product, which is critical in industries such as construction and automotive.

Applications of Edge Channel Roll Forming Machines

The applications of edge channel roll forming machines are vast and varied. In the construction industry, edge channels are used in framing systems, creating sturdy support structures for buildings. In automotive manufacturing, these channels are integrated into vehicle frames, ensuring durability and safety. Additionally, edge channels find their way into the production of industrial equipment, HVAC systems, and electronic enclosures.

Conclusion

In conclusion, the edge channel roll forming machine represents a significant advancement in metal forming technology. With its ability to produce high-precision, high-quality components efficiently, it plays a crucial role in modern manufacturing. As industries continue to evolve and demand for innovative products increases, the edge channel roll forming machine will undoubtedly remain an indispensable tool for manufacturers seeking to enhance their production capabilities and maintain competitive advantage. Investing in such machinery not only improves manufacturing efficiency but also elevates the overall quality of produced components, reinforcing the importance of advanced technology in today's industrial landscape.