Double Layer Roof Forming Machine An Overview

In the modern construction industry, the demand for innovative and efficient building materials is ever-increasing. Among the emerging technologies, the double layer roof forming machine has gained significant attention for its ability to streamline the production of roofing sheets. This advanced machinery offers a unique solution for creating durable and aesthetically pleasing roofs, making it a popular choice among manufacturers and builders alike.

What is a Double Layer Roof Forming Machine?

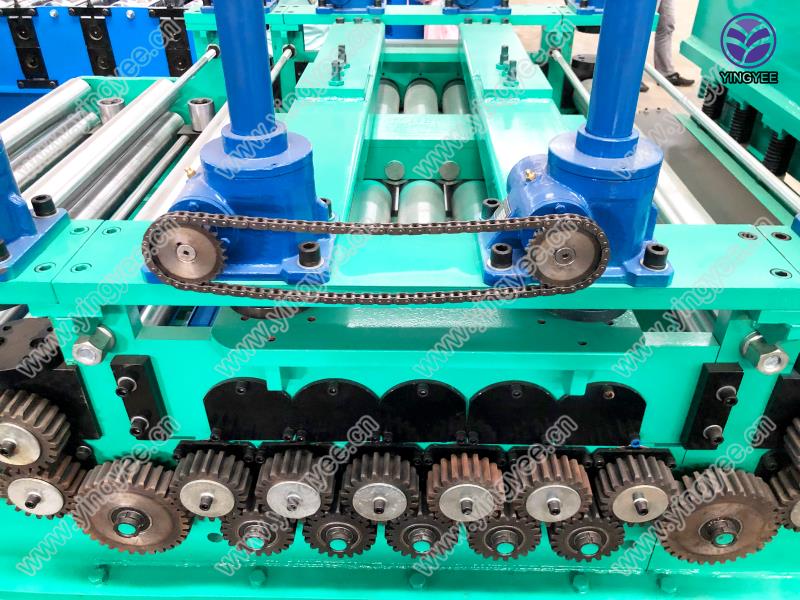

A double layer roof forming machine is a specialized piece of equipment designed to produce two different profiles of roof panels from a single line. This innovation not only saves time and space but also ensures that manufacturers can cater to diverse client needs without the necessity of multiple machines. Typically, these machines work by feeding metal coils into the forming station, where they undergo a series of processes, including forming, cutting, and shaping, to produce the desired roofing sheets.

Key Features and Benefits

1. Versatility One of the most significant advantages of the double layer roof forming machine is its versatility. It can create a variety of panel profiles, accommodating different architectural styles and preferences. This flexibility allows manufacturers to expand their product offerings without investing in additional equipment.

2. Efficiency The dual functionality of these machines significantly enhances production efficiency. By eliminating the need for separate machines, manufacturers can streamline their operations, reducing production times and labor costs. This efficiency translates to lower prices for consumers and increased profitability for businesses.

3. Quality Control Modern double layer roof forming machines are equipped with advanced technology and features that ensure high precision and consistency in the production process. Automated controls, sensors, and feedback systems help maintain quality standards, resulting in durable and reliable roofing materials.

4. Space-Saving Design In today’s fast-paced industrial environment, space is often at a premium. The double layer roof forming machine optimizes production space by combining two forming lines into one, making it an ideal solution for manufacturers with limited floor space.

5. Reduced Waste The efficiency of these machines also extends to material usage. By maximizing output and minimizing errors, manufacturers can reduce waste during production. This not only benefits the environment but also lowers material costs.

Applications

The double layer roof forming machine is widely used in various applications. It is particularly popular in the construction of warehouses, factories, commercial buildings, and residential homes. The roofing sheets produced by these machines are not only functional but also add to the overall aesthetic appeal of the structures. Additionally, the machine can adapt to different materials, including galvanized steel and aluminum, further broadening its use in different construction contexts.

Conclusion

As the construction industry continues to evolve, the double layer roof forming machine stands out as a vital technological advancement. Its unique combination of versatility, efficiency, and quality control makes it an essential tool for manufacturers looking to meet the growing demand for diverse roofing solutions. By investing in this innovative machinery, companies can enhance their production capabilities, satisfy client needs, and ultimately contribute to the evolution of modern architectural design. In a world where time and resources are increasingly constrained, the double layer roof forming machine represents a significant leap forward, providing a sustainable and efficient approach to roofing production.