Understanding the Drywall Stud Machine A Key Tool in Construction

In the world of construction, efficiency and precision are paramount. Among the myriad of tools and machinery that facilitate the building process, the drywall stud machine stands out as an essential device. This innovative machine streamlines the process of framing and installing drywall, making it a favorite among contractors and builders alike.

The primary function of a drywall stud machine is to automate the process of creating metal or wooden studs, which are critical components in the construction of walls and ceilings. Traditionally, creating these studs involved manual measurements, cutting, and assembling, processes that could be time-consuming and prone to error. With the advent of drywall stud machines, this has changed dramatically. These machines can produce perfectly cut studs in a fraction of the time it would take to do so manually.

One of the key benefits of using a drywall stud machine is the consistency it offers

. When constructing walls, uniformity is essential to ensuring that the drywall fits properly and that the walls are structurally sound. The machine eliminates human error, guaranteeing that each stud is made to the exact specifications required. This precision not only enhances the quality of the work but also reduces waste, as fewer mistakes lead to less unusable material.

Moreover, drywall stud machines are designed for versatility. They can accommodate various types of materials, including lightweight steel and traditional wood, making them suitable for different building projects. This adaptability is particularly beneficial as building trends evolve, with more projects shifting towards sustainable and lightweight materials.

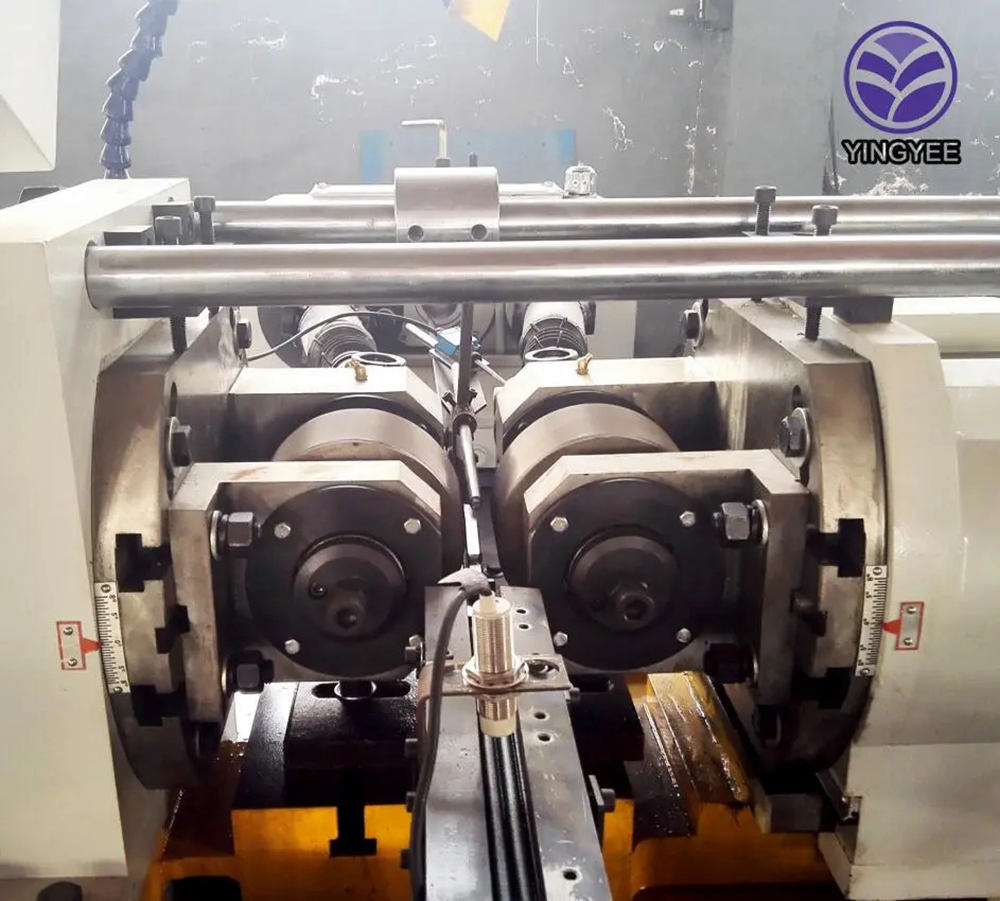

The operation of a drywall stud machine is relatively straightforward, often requiring just one or two operators. Most modern machines are equipped with advanced technology, including programmable settings that allow workers to adjust the size and shape of the studs according to the project's requirements. Some models even feature integrated cutting tools, which further streamline the process by allowing for precise cuts without the need for additional equipment.

Investing in a drywall stud machine not only enhances productivity but also improves the overall workflow on a construction site. By reducing the time and labor costs associated with manual stud production, contractors can allocate resources more efficiently and focus on other critical aspects of the project. This shift can lead to faster project completion, which is a significant advantage in the competitive construction industry.

In summary, the drywall stud machine is a transformative tool in the construction realm. It accelerates the stud production process, enhances accuracy, and supports a variety of building materials. As the construction industry continues to evolve, machines like these will undoubtedly play a crucial role in meeting the demands of modern construction projects. For builders looking to improve efficiency and output, incorporating a drywall stud machine into their arsenal is a strategic decision that pays off in both time and quality.