Understanding the intricacies of a drywall stud machine is crucial for professionals in the construction and manufacturing industries. When investing in such a machine, it's imperative to not only recognize its technical specifications but also understand the experience and expertise it brings to the workflow.

Drywall stud machines are essential for creating metal studs that are used in framing drywall partitions in commercial and residential buildings. The efficiency of these machines directly impacts project timelines and overall construction efficiency, thus choosing the right machine is a critical decision for any construction project manager or factory owner.

A reliable drywall stud machine must exhibit remarkable precision and durability. These machines usually leverage advanced technology to provide precise cuts and bends, which are vital for ensuring that the studs meet the exact specifications required by project blueprints. The precision provided by these machines helps in reducing material wastage, which not only works towards sustainability but also significantly cuts costs over time.

In terms of expertise, the operation of a drywall stud machine requires skilled personnel who understand its functionalities and maintenance needs. Operators should be adequately trained in managing the machine’s sophisticated features, including its digital interface, adjustment settings, and safety protocols. Regular training ensures that operators can maximize machine performance while adhering to industry safety standards.

When considering the authoritativeness of a drywall stud machine brand, it is essential to look into its market reputation, history of innovation, and user reviews. Leading brands often provide extensive warranties, after-sales support, and detailed user manuals that reflect their confidence in their products. These elements are not just value-added services but are also indicators of the manufacturer’s commitment to quality and customer satisfaction.

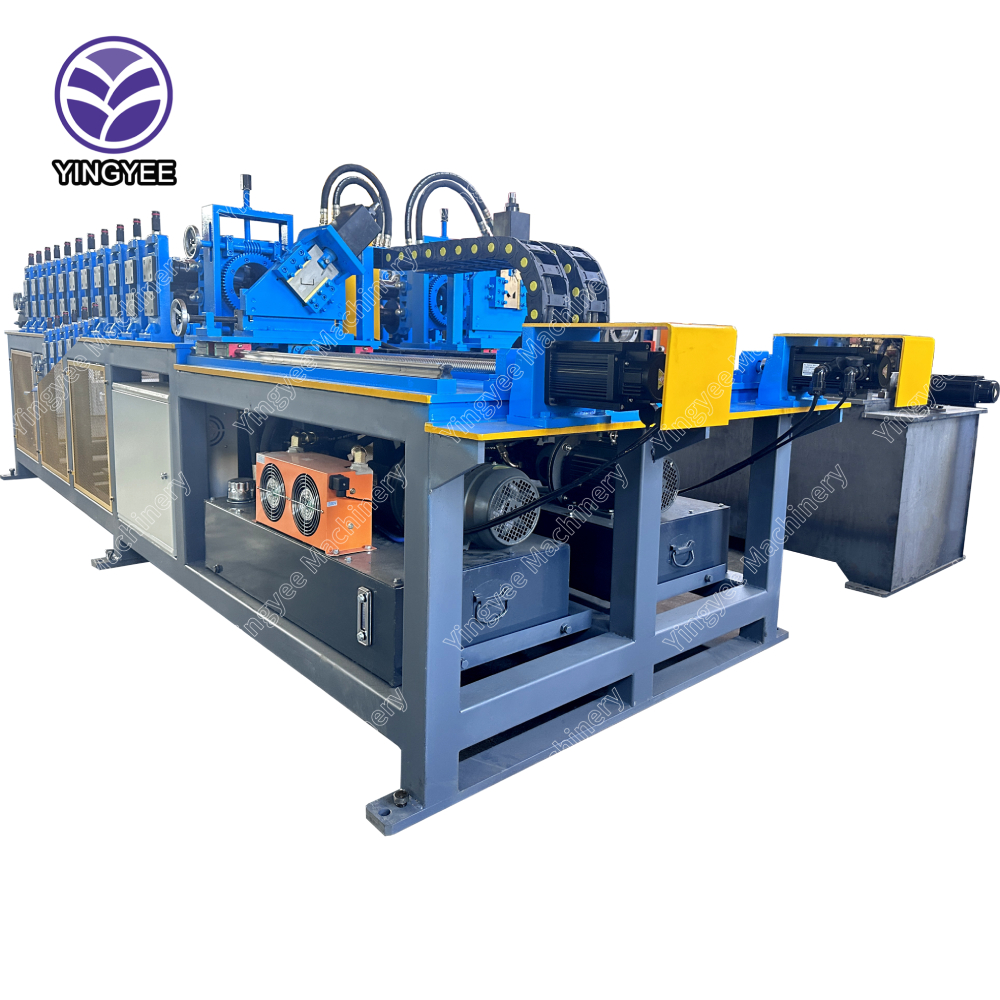

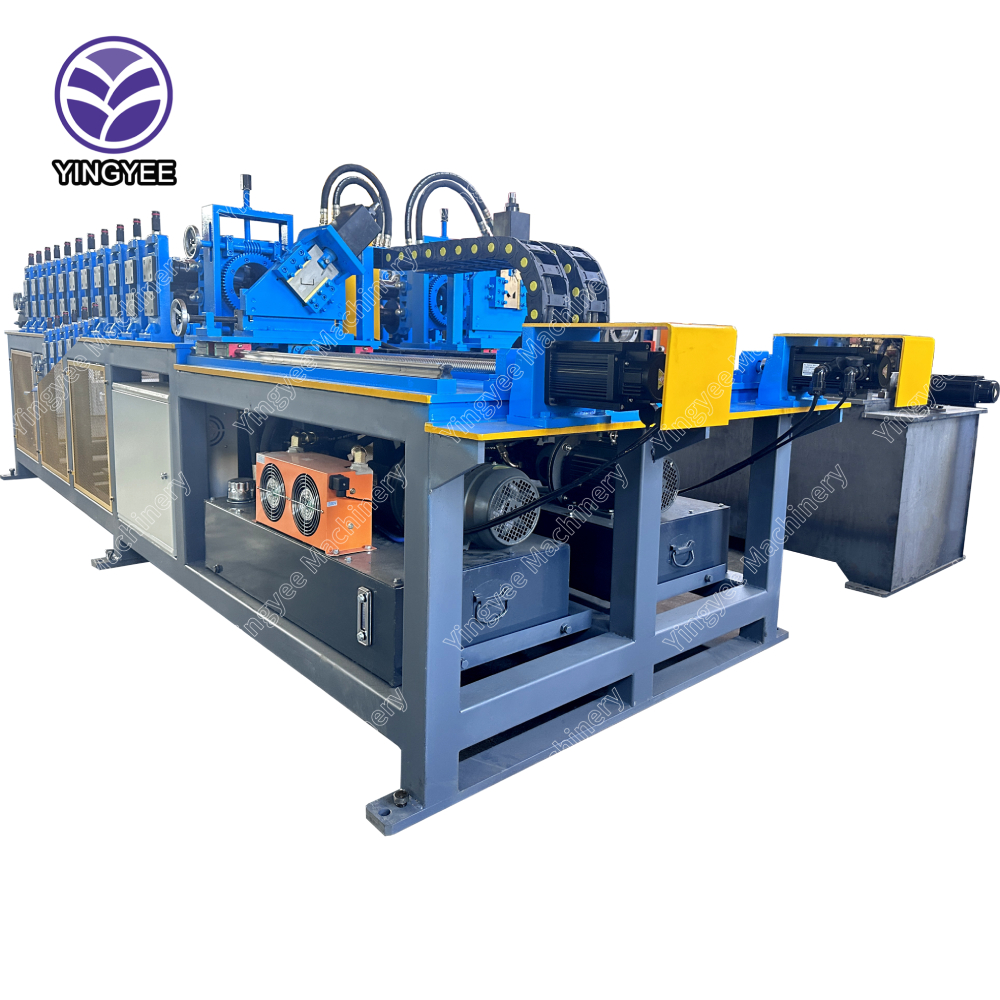

drywall stud machine

Trustworthiness in the context of drywall stud machines extends beyond brand reputation. It involves assured consistency in machine performance over extended periods. Companies manufacturing these machines often provide testing certifications that corroborate their reliability under various operational conditions. Furthermore, verified customer testimonials and case studies can be indispensable in ascertaining which brands or models consistently deliver on their promises.

Adaptability is another crucial factor to consider. A high-quality drywall stud machine should be capable of adapting to different designs and specifications, accommodating changes in project requirements without compromising on quality. Machines that offer programmable settings and customizable options are valuable assets, allowing businesses to scale up production efficiently while maintaining flexibility.

It's also prudent to take into account the technological advancements embedded within these machines. Integration with IoT devices, automation features, and real-time data analytics are no longer mere enhancements but necessities for modern construction demands. These technological features not only enhance productivity but also offer insights into optimizing operational efficiency.

Finally, the economic aspect cannot be overlooked. While the initial investment in a drywall stud machine might be significant, the return on investment is realized through reduced labor costs, minimized material wastage, and enhanced output quality. Construction firms should evaluate machine performance data, such as throughput rates and downtime statistics, to ensure they are getting the maximum value for their investment.

In conclusion, selecting a drywall stud machine is a decision that intertwines experience, expertise, authoritativeness, and trustworthiness. It is a decision that speaks to the heart of a construction project’s success, influencing everything from timeline adherence to cost efficiency. By focusing on these critical factors, industry professionals can ensure that they choose not just a machine but a robust partner in their construction endeavors.