Exploring the Drywall Stud Machine Revolutionizing Construction Efficiency

In the world of construction, efficiency and precision are paramount. As building projects become increasingly complex, the tools and machines we use must adapt to meet rising demands. One such innovative tool is the drywall stud machine, a vital component in modern construction.

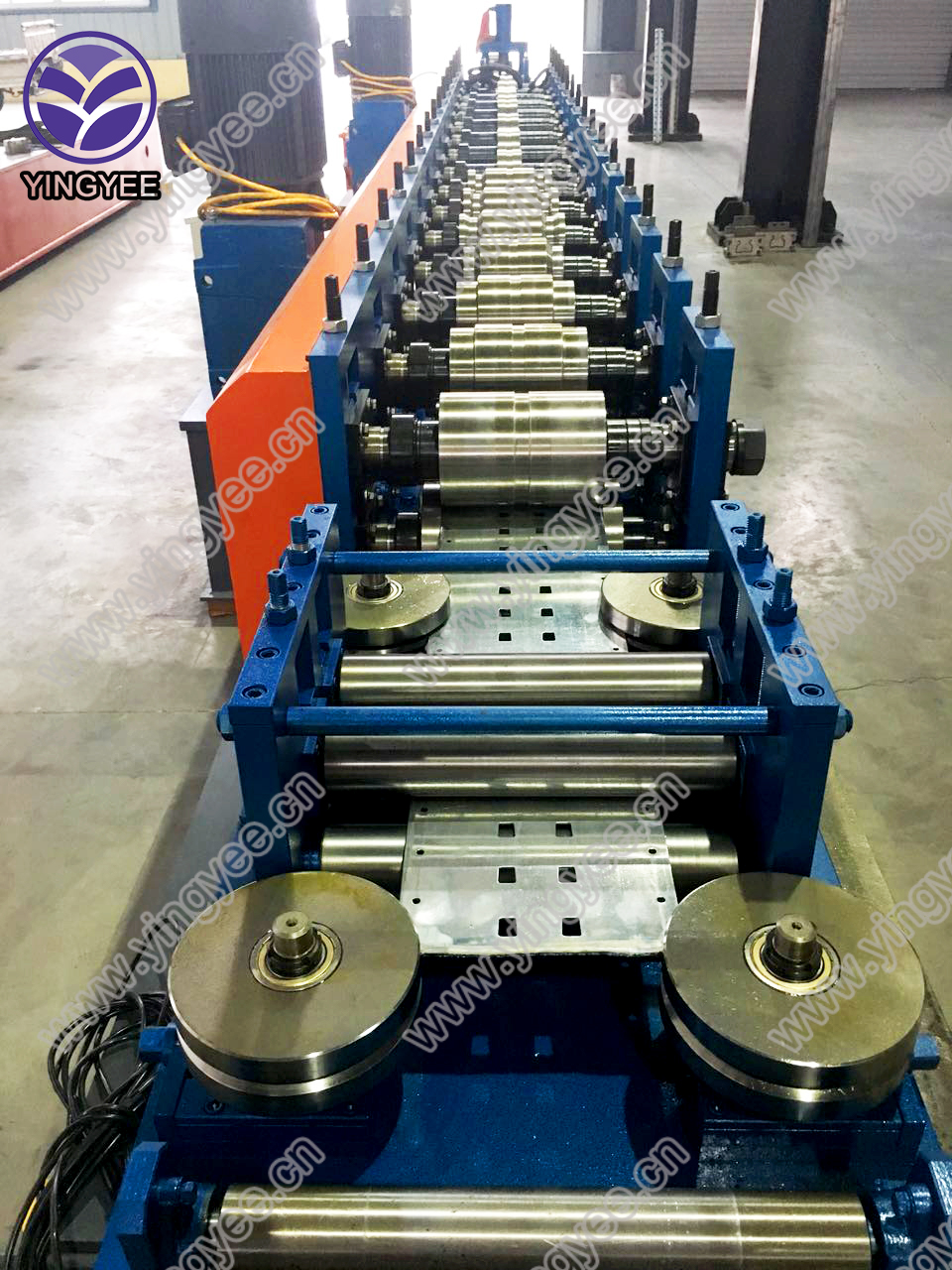

A drywall stud machine is designed to streamline the process of framing walls and ceilings with drywall. Traditionally, the manual method of installing studs—essential vertical or horizontal supports—can be labor-intensive and time-consuming. The introduction of this machine automates the cutting, sizing, and fastening processes, allowing contractors to significantly reduce both labor costs and installation time.

At the heart of the drywall stud machine is its ability to accurately cut metal or wooden studs to the desired length. The precision of automated cutting minimizes waste, ensuring that materials are used efficiently. This capability is particularly valuable given the rising costs of building materials in recent years. By optimizing resource use, contractors not only save money but also contribute to a more sustainable construction process.

Moreover, the drywall stud machine often features advanced technology such as programmable logic controllers (PLCs) and user-friendly interfaces. These allow users to input specifications easily, adjusting dimensions to meet the unique requirements of each project. Such flexibility is crucial in an industry where no two jobs are exactly the same.

Another significant advantage of the drywall stud machine is its ability to enhance safety on construction sites. Manual labor often exposes workers to risks associated with repetitive movements and heavy lifting. By automating these tasks, the machine reduces the physical strain on workers, helping to decrease injury rates and enhance overall workplace safety.

In addition to safety, the consistency provided by the drywall stud machine leads to higher quality construction. The machine ensures uniformity in stud dimensions, which is essential for the subsequent installation of drywall. Uneven studs can lead to problems such as cracks, gaps, and increased energy costs due to airflow between the wall and the drywall. With a drywall stud machine, builders can achieve a tighter fit, ultimately resulting in a more polished finish.

Furthermore, the implementation of a drywall stud machine aligns with the trend towards digital integration in the construction industry, known as Construction 4.0. As this movement gains momentum, tools and machinery that utilize smart technology become increasingly important. The ability to connect machines to digital platforms enhances project management, tracking, and collaboration, setting the stage for a future where construction is not just faster but also smarter.

In conclusion, the drywall stud machine is more than just a labor-saving device; it is a technological marvel that encapsulates the evolution of the construction industry. By promoting efficiency, safety, and sustainability, this machine embodies the principles that will drive the industry forward. As we look to the future, it is clear that embracing such innovations will be key to meeting the growing challenges of construction in a rapidly changing world. The drywall stud machine is indeed a cornerstone of modern building practices, proving that technology and craftsmanship can coexist harmoniously.