Understanding Drywall Roll Forming Machines

Drywall roll forming machines are essential equipment in the construction industry, particularly in the production of drywall and related materials. These machines are designed to create various metal profiles that are crucial for the assembly and support of drywall structures, which are widely used in commercial and residential buildings. This article aims to delve into the workings and benefits of drywall roll forming machines, highlighting their significance in modern construction.

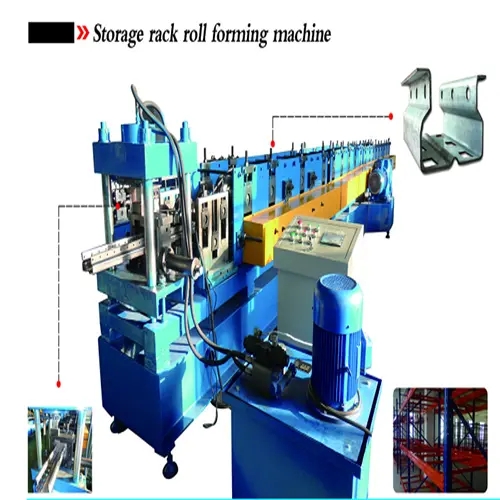

At its core, a drywall roll forming machine operates by taking raw coil materials, typically made from steel or aluminum, and processing them into specific shapes and thicknesses necessary for drywall applications. The process begins when the metal coils are fed into the machine. The machine then uncoils and flattens the material before guiding it through a series of rollers that progressively shape it into the desired profile. These profiles can include channels, studs, and tracks, which are pivotal in the installation of drywall panels.

One of the significant advantages of drywall roll forming machines is their efficiency. Traditional methods of creating metal parts often involve labor-intensive processes that can be time-consuming and costly. In contrast, roll forming offers a continuous production line that optimizes output and reduces waste by using materials more effectively. This high-speed manufacturing process ensures that bulk quantities of metal profiles can be produced quickly, meeting the high demands of the construction market.

Moreover, the precision of drywall roll forming machines is another considerable benefit. These machines use advanced technology, including computerized controls, to ensure that each profile produced meets strict industry standards. This level of accuracy is essential for ensuring that the drywall installation process is seamless and that structures remain stable and secure. Consistency in product dimensions also allows for ease of assembly, reducing the need for adjustments on-site.

Another key aspect of drywall roll forming machines is their versatility. Manufacturers can easily switch out different rollers and die setups to produce a variety of profiles. This adaptability allows companies to cater to specific project requirements and customer preferences without investing in multiple pieces of heavy machinery. With just one machine, businesses can produce an extensive range of products, from simple studs to more complex framing systems.

In addition to their efficiency and versatility, drywall roll forming machines are typically designed with durability in mind. Constructed from robust materials, these machines are built to withstand the wear and tear associated with continuous production. With proper maintenance, a roll forming machine can have a long operational lifespan, delivering substantial returns on investment for manufacturers.

As sustainability becomes increasingly important in construction, drywall roll forming machines also offer eco-friendly benefits. By utilizing materials efficiently and minimizing waste, they contribute to greener manufacturing practices. Additionally, manufacturers can recycle scrap metal generated during the forming process, further reducing the environmental impact.

In conclusion, drywall roll forming machines play a vital role in the modern construction sector. Their efficiency, precision, and versatility make them indispensable tools for producing high-quality metal profiles used in drywall applications. As the industry continues to evolve, these machines will undoubtedly remain at the forefront of drywall manufacturing, helping builders meet the ever-growing demands of sustainable and efficient construction.