The drywall roll forming machine stands as a pivotal innovation in modern construction, offering precision and efficiency that transforms the fabrication process of drywall metal profiles. This advanced machinery is engineered to mold flat sheet metal into consistent and accurate shapes, which are fundamentally crucial for constructing drywall frameworks. Understanding the operation, benefits, and technological advancements of this machine can offer invaluable insights for industry professionals and businesses looking to optimize their construction processes.

Distinctly designed to cater to the growing demands of the construction industry, the drywall roll forming machine embodies the essence of expertise and craftsmanship. This sophisticated equipment leverages a series of sequential processes that mold metal sheets through a combination of pressure and bending. The result is a meticulously crafted profile that maintains its structural integrity and dimensional accuracy. By adopting this machine, manufacturers are empowered to produce metal studs and tracks that align with industry standards, thereby significantly enhancing construction reliability.

What sets the drywall roll forming machine apart is its operational efficiency and versatility. Its ability to process various metals—ranging from galvanized steel to stainless steel—enables manufacturers to meet specific project requirements without compromising on quality. Moreover, tunable settings allow for customization, catering to diverse profiles and dimensions needed in drywall installation. The ease of configuration and response to dynamic production requirements render this machine a tangible asset to any production line.

In terms of experience, many manufacturers have witnessed firsthand the substantial improvements in production timelines and quality control when integrating this machine into their workflow. Detailed case studies indicate a marked decrease in material wastage, owing to the precision with which profiles are formed, minimizing the need for subsequent adjustments or corrections. Coupled with lower operational costs due to minimal manual intervention, the machine facilitates a strategic advantage, enhancing competitive standing in the market.

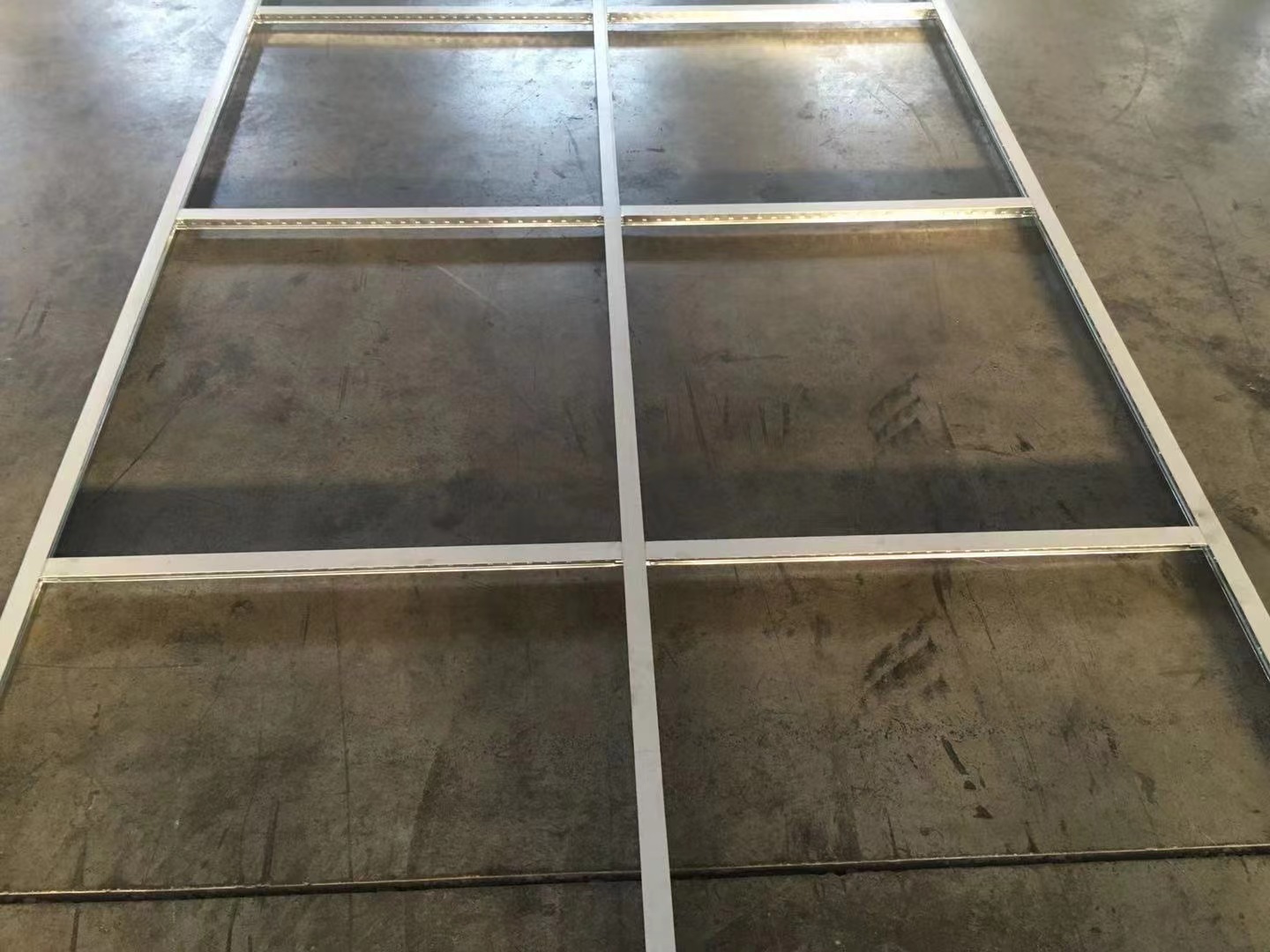

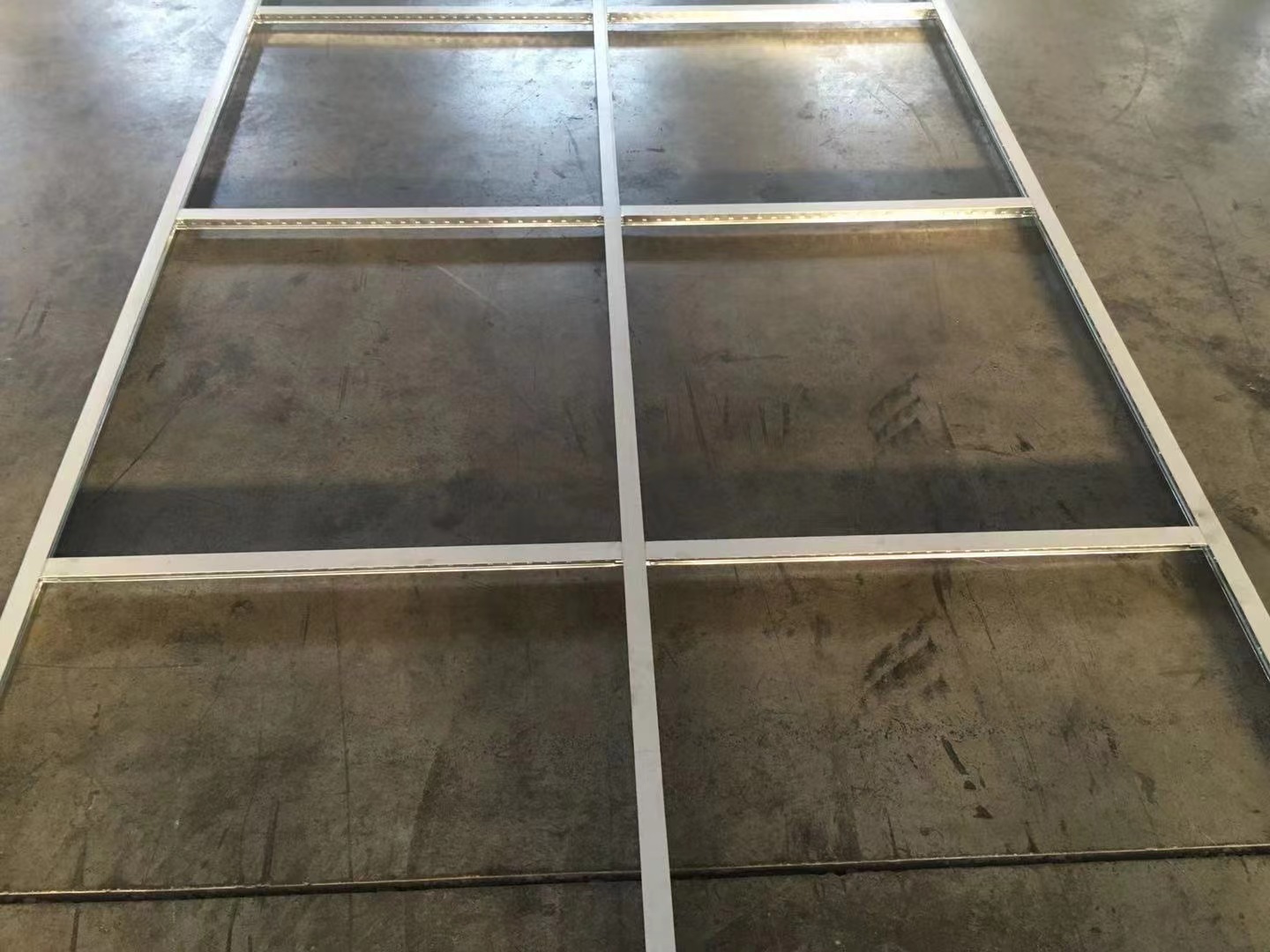

drywall roll forming machine

The credibility of the drywall roll forming machine is reinforced by the extensive research and development invested by leading manufacturers. These companies prioritize innovation and reliability, ensuring that their equipment not only conforms to stringent safety regulations but also surpasses the quality benchmarks set by traditional fabrication methods. This commitment to excellence is further exemplified by rigorous testing procedures and the use of advanced technology, such as computer numerical control (CNC), which guarantees precision and consistency across large-scale productions.

Trust forms the cornerstone of adopting new industrial technology, and the drywall roll forming machine has garnered significant trust through proven performance and dependability.

Manufacturers provide comprehensive training and support, ensuring seamless integration with existing systems. Additionally, the machine's robust construction and low-maintenance design mitigate downtime, allowing for uninterrupted production cycles.

In conclusion, the drywall roll forming machine embodies a blend of expert engineering, authoritative technological advancement, and proven dependability, driving forward the capabilities of modern construction. For those in the industry seeking to enhance their operational efficiency and product quality, investing in such machinery is not merely a choice but a strategic imperative that holds the promise of elevating production standards and fostering sustained business growth.