Understanding Drywall Roll Forming Machines A Comprehensive Overview

In the construction and building materials industry, efficiency and precision are paramount. One of the innovations that have significantly improved production capabilities is the drywall roll forming machine. This advanced equipment is essential for efficiently manufacturing drywall components, which are critical for modern construction, especially in residential and commercial buildings.

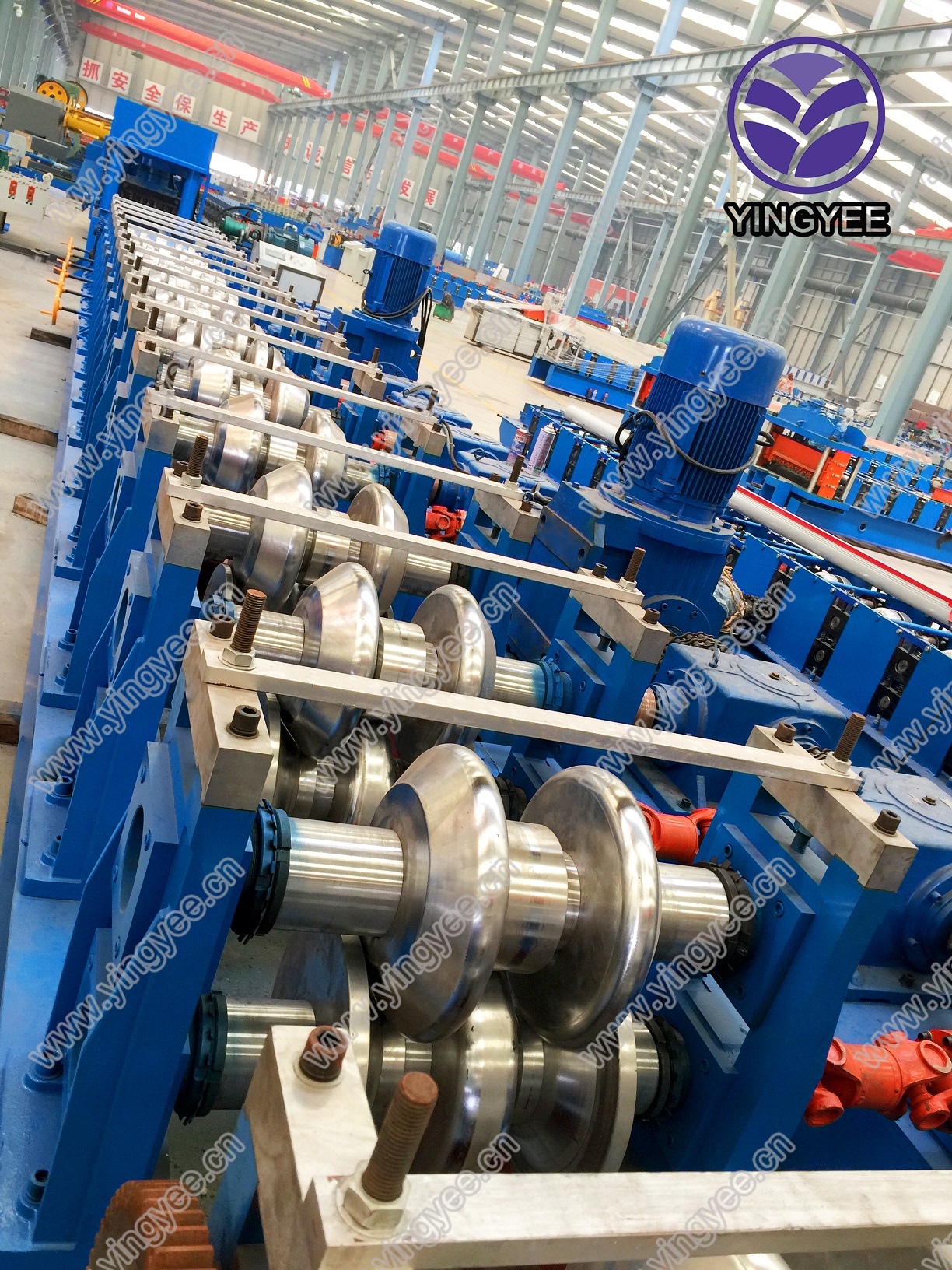

A drywall roll forming machine works by continuously feeding raw materials, typically metal coils, through a series of rollers that shape the material into the desired profile

. These machines can create different types of drywall products including metal studs, tracks, and corner beads. The use of these machines not only streamlines the manufacturing process but also ensures uniformity and high-quality output.Key Features and Advantages

The primary advantage of using a drywall roll forming machine lies in its automation capabilities. This technology allows for mass production with minimal manual intervention, reducing labor costs and production time. Advanced models are equipped with CNC (Computer Numerical Control) technology, enabling precise adjustments to the forming process for various specifications. This flexibility allows manufacturers to quickly adapt to changing market demands or custom orders without the need for extensive reconfiguration.

Another critical benefit is the material efficiency provided by roll forming machines. Traditional methods often result in significant waste, while roll forming processes minimize scrap material, leading to a more sustainable production model. Moreover, the durability of the products manufactured with these machines is often superior, making them a preferred choice in construction where longevity and strength are required.

Applications in the Construction Industry

Drywall roll forming machines are pivotal in producing components used in interior wall systems. Metal studs created from these machines are a preferred alternative to wood studs due to their resistance to warping, pests, and fire. They are also crucial in creating ceilings, partitions, and various architectural designs, contributing to the growing trend of metal framing in modern architecture.

Besides structural applications, the machines also produce components for aesthetic embellishments such as decorative moldings and trims. This versatility has positioned drywall roll forming machines as an essential tool for contractors and builders looking to enhance both the functionality and appearance of their projects.

Conclusion

The drywall roll forming machine represents a significant technological advancement in the construction industry. By marrying speed, precision, and material efficiency, these machines enable manufacturers to produce high-quality drywall components that meet the demands of today’s construction projects. As the industry continues to evolve, the role of drywall roll forming machines will likely expand, paving the way for innovative building solutions that prioritize sustainability and efficiency. Investing in such technology not only enhances production capabilities but also positions businesses at the forefront of an increasingly competitive market.