Understanding Drawer Slide Making Machinery

In the manufacturing sector, efficiency and precision are paramount. As furniture design evolves, the demand for high-quality drawer slides has surged. Drawer slide making machinery plays a crucial role in meeting this demand, offering solutions that enhance production speed and product quality. In this article, we will explore the importance of drawer slide making machinery, its components, and the impact it has on the furniture industry.

The Importance of Drawer Slides

Drawer slides are essential components in furniture design, providing smooth motion and reliable functionality. They enable drawers to open and close seamlessly, enhancing usability and user experience. With diverse designs available, including soft-close and full-extension slides, the manufacturing process of these components must be both efficient and adaptable to various specifications. This is where drawer slide making machinery comes into play.

Components of Drawer Slide Making Machinery

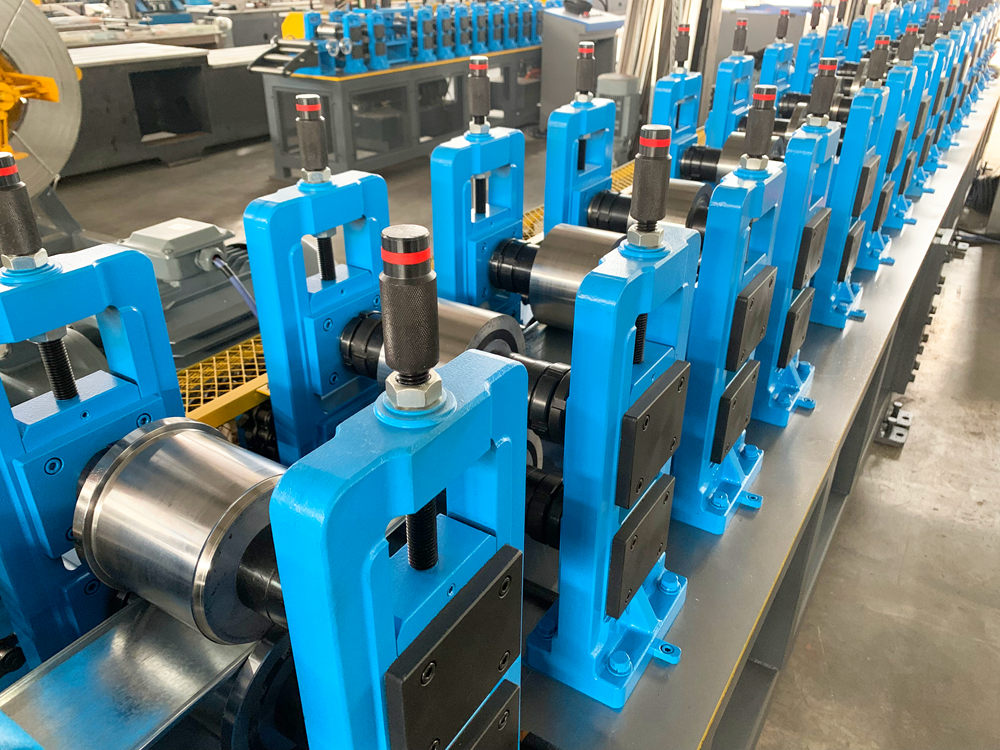

Drawer slide making machinery consists of several key components that work in unison to produce high-quality slides. Here are the primary components

1. Cutting Machines These machines are responsible for precisely cutting raw materials, such as metal or high-density polymers, into the required dimensions for the drawer slides. Accurate cuts minimize waste and ensure consistency in production.

2. Forming Machines Once the raw materials are cut, they undergo shaping through forming machines. This process includes bending, rolling, or stamping to create the specific profiles needed for the slides. Advanced forming technologies ensure the correct shape while maintaining material integrity.

3. Welding and Joining Machines For metal drawer slides, welding or joining processes are essential to assemble different parts seamlessly. These machines use techniques like spot welding or laser welding to ensure strong bonds without compromising quality.

4. Finishing Machines After assembly, drawer slides often require a finishing touch. This can include surface treatments like powder coating or anodizing to enhance durability and aesthetics. Finishing machines contribute significantly to the overall quality of the final product.

5. Quality Control Systems Ensuring that each drawer slide meets industry standards is vital. Quality control systems integrated into the machinery help monitor and inspect each product, detecting any defects to maintain high standards.

Benefits of Advanced Machinery

Modern drawer slide making machinery is designed to improve efficiency and production scalability. These advanced machines offer several benefits

- Increased Production Speed With automation and faster processing capabilities, manufacturers can produce more slides in a shorter amount of time, meeting the growing market demand.

- Enhanced Precision High-precision machinery minimizes errors in production, resulting in uniform and consistent quality in the end product. This is crucial for consumer satisfaction and brand reputation.

- Flexibility and Customization Advanced machinery can be easily adjusted to produce various types of drawer slides, allowing manufacturers to adapt quickly to changing consumer preferences and market trends.

- Cost Efficiency Automating processes reduces labor costs and waste, leading to more cost-effective production methods. This efficiency translates to competitive pricing for consumers.

Conclusion

Drawer slide making machinery is an essential component of the furniture manufacturing industry, responding to the increasing demand for high-quality and reliable products. By integrating advanced technologies in cutting, forming, welding, and finishing, manufacturers can produce drawer slides that enhance the functionality of furniture. As the industry continues to evolve, so too will the machinery that supports it, ultimately leading to innovations that benefit both producers and consumers alike. Embracing these advancements, manufacturers can ensure they remain at the forefront of quality and efficiency in an ever-competitive marketplace.