The Rise of Downspout Machine Manufacturers Innovative Solutions for Rainwater Management

In recent years, the need for effective rainwater management systems has become increasingly vital in urban planning and construction. With the growing concerns around climate change and the resulting erratic weather patterns, the demand for reliable drainage solutions has surged. This trend has paved the way for the emergence of downspout machine manufacturers, who are now playing a critical role in ensuring the efficient management of rainwater. This article explores the significance of downspout machines, the manufacturing process, and the impact of their innovation on the industry.

Understanding Downspout Machines

Downspout machines are specialized equipment used to produce downspouts—vertical pipes that channel rainwater from rooftops to the ground or drainage systems. The efficiency of these machines directly influences the quality and performance of the downspouts, which are essential components in preventing water damage to buildings, reducing erosion, and promoting effective stormwater management.

The primary function of downspouts is to direct rainwater collected from gutters away from the foundation of a building. Without properly functioning downspouts, excess water can accumulate, leading to serious issues such as flooding, mold growth, and structural damage. Therefore, the role of downspout machine manufacturers is not only focused on production but also on creating solutions that contribute to sustainable construction practices.

The Manufacturing Process

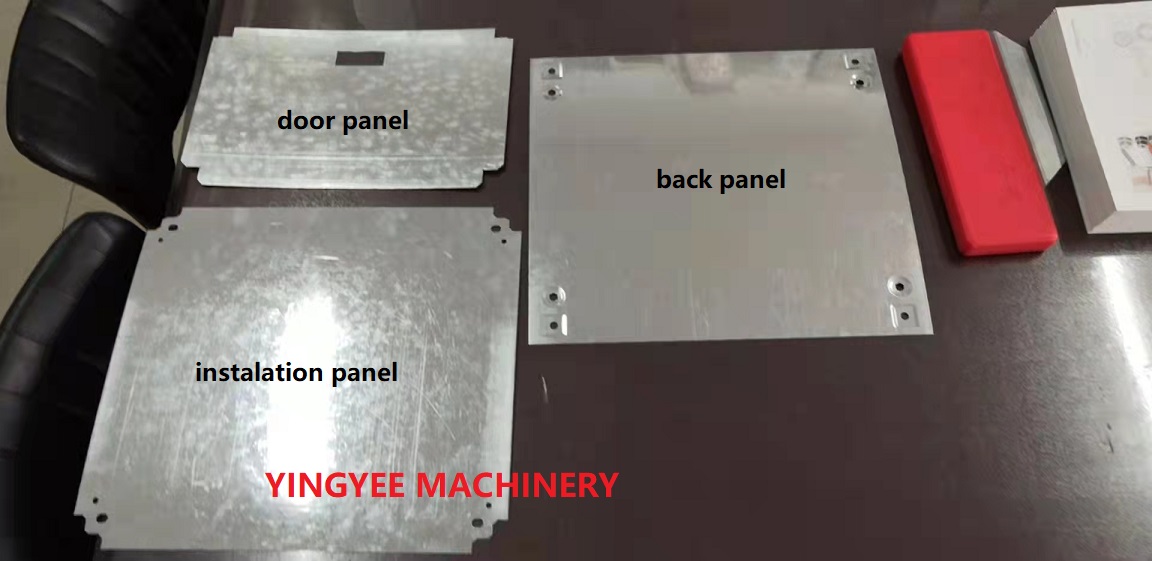

The manufacturing process of downspout machines typically involves several steps, ensuring precision and durability. First, high-quality raw materials such as galvanized steel, aluminum, or PVC are selected based on the specific requirements of the end product. These materials are then fed into the machine, which shapes them into the desired form through a series of bending and cutting operations.

Automation has revolutionized the manufacturing process, allowing for greater efficiency and consistency. Many downspout machine manufacturers incorporate computerized numerical control (CNC) systems, which enable precise measurements and reduce human error. This technological advancement not only enhances production capacity but also allows for customization—meeting the unique needs and specifications of various clients.

Moreover, sustainable practices have become a priority for many manufacturers. This includes using eco-friendly materials and processes that minimize waste and reduce the carbon footprint of production. As the construction industry increasingly adopts green building standards, downspout machines must evolve to align with these environmental considerations.

Innovations in Downspout Technology

Innovation is at the forefront of downspout machine manufacturing. As manufacturers strive to improve the efficiency and effectiveness of their products, several advancements have emerged. For instance, newer downspout designs feature integrated systems for water collection and redistribution, enhancing the overall efficacy of rainwater management.

Additionally, advancements in materials science have led to the development of stronger, lighter, and more corrosion-resistant materials. This not only extends the lifespan of downspouts but also reduces maintenance requirements—providing long-term cost savings for building owners.

Smart technologies are also making their way into downspout systems. Manufacturers are now exploring the integration of smart sensors that monitor water flow and detect blockages, alerting property owners to potential issues before they escalate.

The Future of Downspout Machine Manufacturers

The future of downspout machine manufacturers looks promising as the focus on sustainable construction and efficient water management continues to grow. As cities seek to implement effective stormwater management strategies, the demand for high-quality downspout machines will likely increase.

Furthermore, collaboration between manufacturers, architects, and civil engineers will be crucial in designing systems that integrate seamlessly into modern building practices. By working together, these stakeholders can develop innovative solutions that address current challenges while anticipating future needs.

In conclusion, downspout machine manufacturers are at the heart of a critical industry that addresses essential aspects of urban planning and sustainability. Through innovative practices, advanced technologies, and a commitment to quality, these manufacturers are not just producing downspouts; they are contributing to a more resilient and sustainable future for our communities. As the importance of effective rainwater management continues to rise, so too will the significance of these manufacturers in shaping the built environment.