In the ever-evolving realm of manufacturing, the significance of efficiency and precision cannot be underestimated. Among the myriad of machinery that facilitates optimal production processes, the downpipe roll forming machine stands out. This machine is an essential component in manufacturing, particularly in the construction and infrastructure sectors, where effective water drainage systems are indispensable. But what exactly makes the downpipe roll forming machine not only a necessity but also a smart investment for businesses aiming for scalability and precision?

The downpipe roll forming machine is designed for creating precise and uniform downpipes, which are integral to directing rainwater from roofs to drainage systems, thus preventing water damage. When speaking of experience, those who have integrated these machines into their manufacturing processes report substantial gains in both productivity and product quality. Unlike traditional methods that might require more time and result in variable product quality, a roll forming machine ensures consistency and reduces waste, ultimately leading to cost savings in raw materials and time.

From an expertise standpoint, the engineering behind downpipe roll forming machines demonstrates a depth of innovation that aligns with the needs of contemporary manufacturing environments. Leveraging advanced technology, these machines can automatically adjust to different profiles and sizes, offering flexibility without compromising on speed. Professionals in the industry appreciate the intuitive design, which allows for easy adjustments and minimal downtime. This adaptability caters to a wide range of production requirements from small-scale projects to extensive commercial constructions, making it a versatile asset.

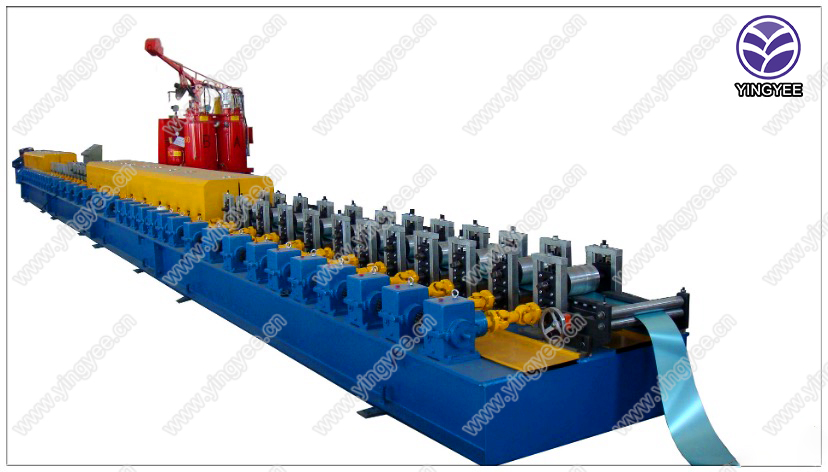

downpipe roll forming machine

When it comes to authoritativeness, manufacturers of downpipe roll forming machines are often leaders in the field, developing and refining these machines through decades of research and practice. They tend to operate within stringent standards, ensuring each machine not only meets but exceeds quality expectations. This commitment to excellence is reflected in the technical support and training offered to users.

Such comprehensive support networks enable operators to harness the full potential of the equipment and stay ahead of the curve with emerging manufacturing trends.

Trustworthiness is a benchmark that the downpipe roll forming machine satisfies through its reliability and long service life. Testimonials from users frequently highlight the minimal maintenance requirements and robust construction that withstands rigorous daily use. These machines are built with high-grade materials resistant to wear and tear, which fosters a strong sense of security in operational stability. Additionally, established manufacturers often provide warranties and guarantees, reassuring clients of the product’s durability and performance, which further cements trust in the investment.

In conclusion, integrating a downpipe roll forming machine into your production line is not merely a decision to upgrade equipment, but a strategic move to enhance operational efficiency and ensure quality output. With a proven track record of reliability and flexibility, these machines are indispensable for businesses looking to heighten their manufacturing prowess. The experience of increased productivity, backed by expert engineering, authoritative industry standing, and trustworthy operation, underscores why investing in such technology is forward-thinking and conducive to sustainable growth.