Down Pipe Roll Forming Machine An Overview

The down pipe roll forming machine is an essential piece of equipment in the manufacturing industry, specifically designed for producing downpipes used in drainage systems. These machines are integral to the construction of residential and commercial buildings, ensuring that rainwater is efficiently channeled away from roofs to prevent water damage. In this article, we will delve into the workings, benefits, and importance of down pipe roll forming machines in modern construction.

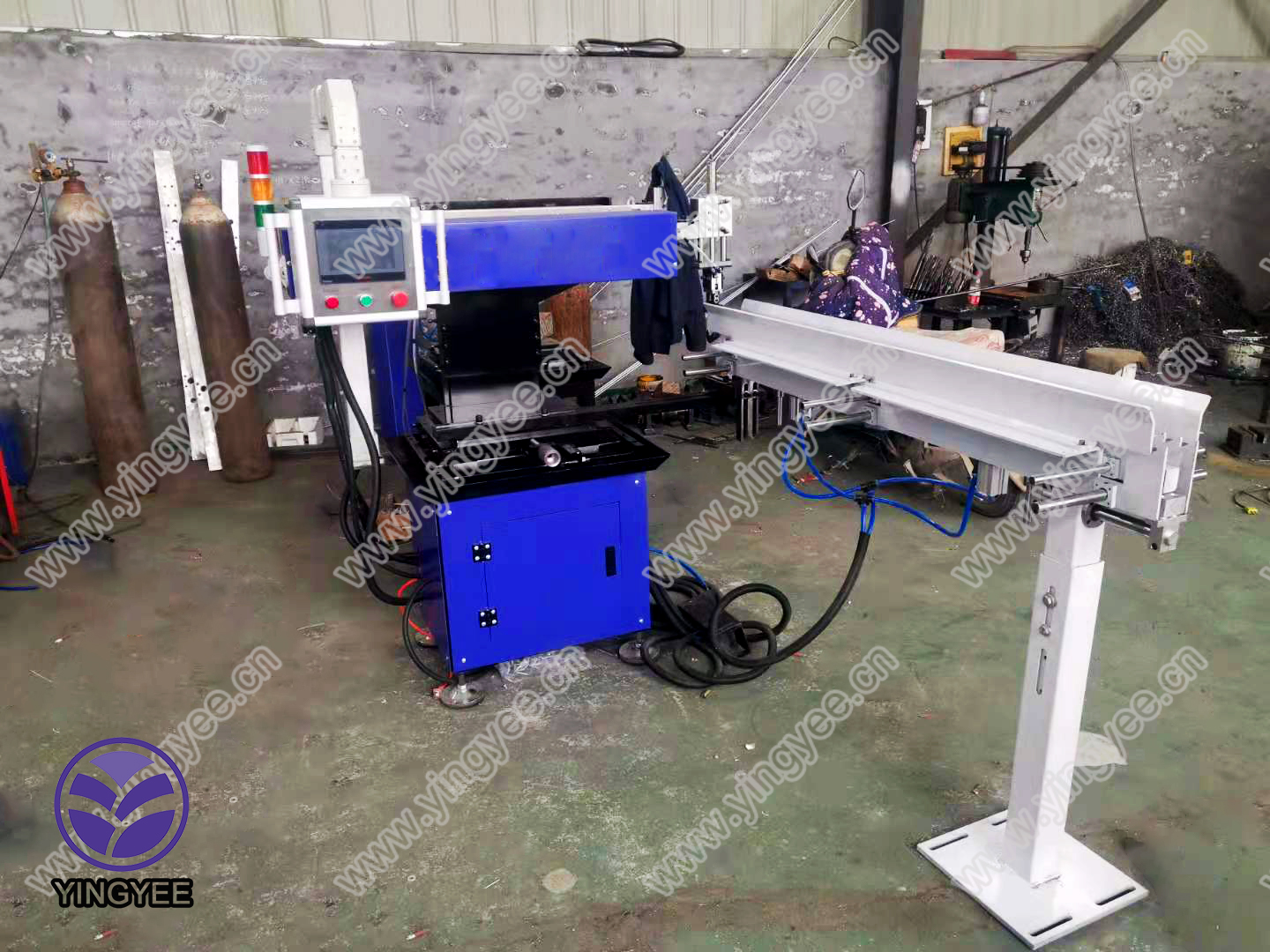

What is a Down Pipe Roll Forming Machine?

A down pipe roll forming machine is a specialized device that shapes metal sheets into downpipes through a series of continuous rolling processes. The machine typically utilizes steel or aluminum as raw materials, which are fed through a series of rollers that progressively shape the metal into the desired profile. The process involves various stages, including cutting, bending, and welding, to produce finished products ready for installation.

How Does It Work?

The operation of a down pipe roll forming machine begins with the feeding of metal strips into the machine. The metal passes through several sets of rollers, which are designed to form the material into the required section. Each set of rollers has a specific function, gradually transforming the flat metal into a tubular shape. Once the desired profile is achieved, the machine can cut the lengths of the pipes to meet specific requirements.

Some modern down pipe roll forming machines come equipped with automatic features, including programmable logic controllers (PLCs) that optimize production efficiency

. These machines can quickly switch between different downpipe sizes and shapes, thereby increasing their versatility and reducing downtime.Benefits of Down Pipe Roll Forming Machines

1. Efficiency These machines are capable of producing large volumes of downpipes in a relatively short amount of time, enhancing production efficiency and meeting high demand in construction projects.

2. Cost-effectiveness With the use of roll forming technology, manufacturers can produce downpipes with minimal waste. The process optimizes the use of raw materials, leading to lower production costs and increased profitability.

3. Quality Control Automated systems in modern roll forming machines help maintain consistent quality standards. The precision of the machinery ensures that the pipes produced meet the required specifications, reducing the chances of defects and returns.

4. Customizability Manufacturers can easily modify the machine settings to create customized downpipe designs. This flexibility allows for the production of downpipes in various shapes and sizes, adapting to the specific needs of each construction project.

5. Durability Roll-formed downpipes are known for their strength and durability. The process enhances the structural integrity of the pipes, making them more resistant to bending and deformation under pressure.

Importance in Construction

In the construction industry, efficient water management systems are critical. Downpipes play a vital role in directing rainwater away from building foundations, windows, and walls, thereby preventing potential damage and erosion. The use of down pipe roll forming machines ensures a steady supply of high-quality downpipes, which are essential for effective drainage solutions.

Furthermore, as environmental concerns continue to grow, the importance of sustainable building practices is increasingly emphasized. Efficient drainage systems contribute to sustainable construction by preventing water accumulation, which can lead to flooding or soil erosion. By ensuring that quality downpipes are readily available, roll forming machines support environmentally responsible building practices.

Conclusion

The down pipe roll forming machine is a crucial innovation in the manufacturing of construction materials. It not only enhances efficiency and reduces costs but also plays a significant role in promoting quality and sustainability in construction practices. As the demand for effective drainage solutions grows, the significance of down pipe roll forming machines in ensuring robust and reliable infrastructure cannot be overstated. With advancements in technology, these machines are poised to evolve further, continuing to meet the needs of the ever-changing construction landscape.