Understanding Downpipe Roll Forming Machines A Comprehensive Overview

In the world of metal fabrication, downpipe roll forming machines play a crucial role in producing efficient, high-quality components for various applications. These machines are designed to create downpipes, which are essential in controlling rainwater drainage from roofs, thus preventing water damage to buildings. This article will delve into the functionalities, benefits, and applications of downpipe roll forming machines, as well as the technology behind them.

What is a Downpipe Roll Forming Machine?

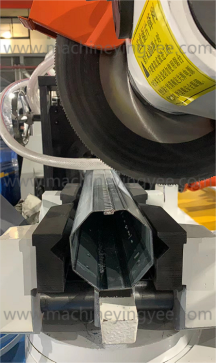

A downpipe roll forming machine is a specialized piece of equipment that shapes metal strips into downpipes through a continuous process. The roll forming method involves feeding a flat metal sheet into a series of rollers that progressively bend and shape the material into the desired profile. This process is highly efficient and can accommodate various materials, including aluminum, stainless steel, and galvanized steel.

The Process of Roll Forming

The roll forming process begins with the preparation of raw materials. Typically, these machines work with a coil of metal sheet, which is uncoiled and fed through the initial set of rollers. Each roller is strategically positioned to perform a specific bend or contour on the metal strip. As the material passes through multiple stations, it is continuously shaped until it reaches the final downpipe profile.

The precision of the rollers is paramount; they are designed based on the desired dimensions of the downpipe, ensuring uniformity and accuracy in each piece produced. Once the downpipe has been formed, it can be cut to the required lengths, completing the process.

Benefits of Using Downpipe Roll Forming Machines

1. Efficiency Roll forming is a continuous process, allowing for high volume production in relatively short time frames. This is particularly advantageous for manufacturers who need to meet large orders quickly.

2. Cost-Effectiveness The initial setup cost for a roll forming machine can be high. However, the efficiency and speed of production eventually lead to lower costs per unit, making it a cost-effective solution for large-scale operations.

3. Customization Downpipe roll forming machines can be tailored to produce a wide range of designs and sizes. Manufacturers can easily adjust the machinery to create custom profiles that meet specific customer requirements.

4. Waste Reduction The roll forming process generates minimal waste compared to other manufacturing methods. Metal strips are formed and cut with little leftover material, promoting a more sustainable operation.

5. Durability and Strength The continuous formation process increases the structural integrity of the downpipes produced. This ensures that the finished products are both lightweight and durable, capable of withstanding harsh weather conditions.

Applications of Downpipe Roll Forming Machines

Downpipe roll forming machines are widely used across various industries. The construction sector is the primary user, as downpipes are essential components in building drainage systems. They are also employed in the production of rainwater goods, such as gutters and downspouts.

In addition, these machines can be utilized in the manufacturing of other products, such as metal frames, channels, and specialized ducts, showcasing their versatility beyond just downpipe production.

Conclusion

In summary, downpipe roll forming machines are a vital tool in modern metal fabrication, providing efficiency, cost-effectiveness, and customization. Their role in producing high-quality downpipes ensures effective rainwater management, protecting buildings from potential water damage. As technology continues to evolve, we can expect these machines to incorporate advanced features, further enhancing their capabilities and applications. For manufacturers looking to improve their production processes, investing in a downpipe roll forming machine can be a significant step towards achieving operational excellence and meeting market demands.