The downpipe machine industry has witnessed a significant transformation with the infusion of technology and innovation, leading to more efficient and durable solutions for water drainage systems. These machines, essential in manufacturing downpipes used in buildings for directing rainwater from roofs to drains, now incorporate advanced features that cater to modern construction needs. This article explores the key aspects of downpipe machines that enhance user experience, demonstrate technical expertise, establish authority in the field, and build trust among consumers and professionals alike.

One of the primary innovations in downpipe machines is the integration of automated systems. Automation not only increases productivity but also ensures precision in cutting and shaping downpipes, resulting in fewer errors and wastage. This refinement is crucial for large-scale operations where time and accuracy are of the essence. Users can expect machines equipped with intelligent controls that allow for seamless operation, even by workers with minimal technical training. These machines are programmed to adjust to various pipe dimensions and materials, making them versatile in different construction environments.

The expertise behind the modern downpipe machine is driven by a deep understanding of material science and engineering. Manufacturers now use high-grade steel and aluminum, known for their strength and corrosion resistance, ensuring the downpipes' longevity and reliability. Furthermore, the machines are designed to handle a variety of materials without compromising on performance, providing users with the flexibility to cater to different customer needs. The design and engineering teams behind these machines continually research and implement new technologies to refine their products, striving to maintain a lead in the industry.

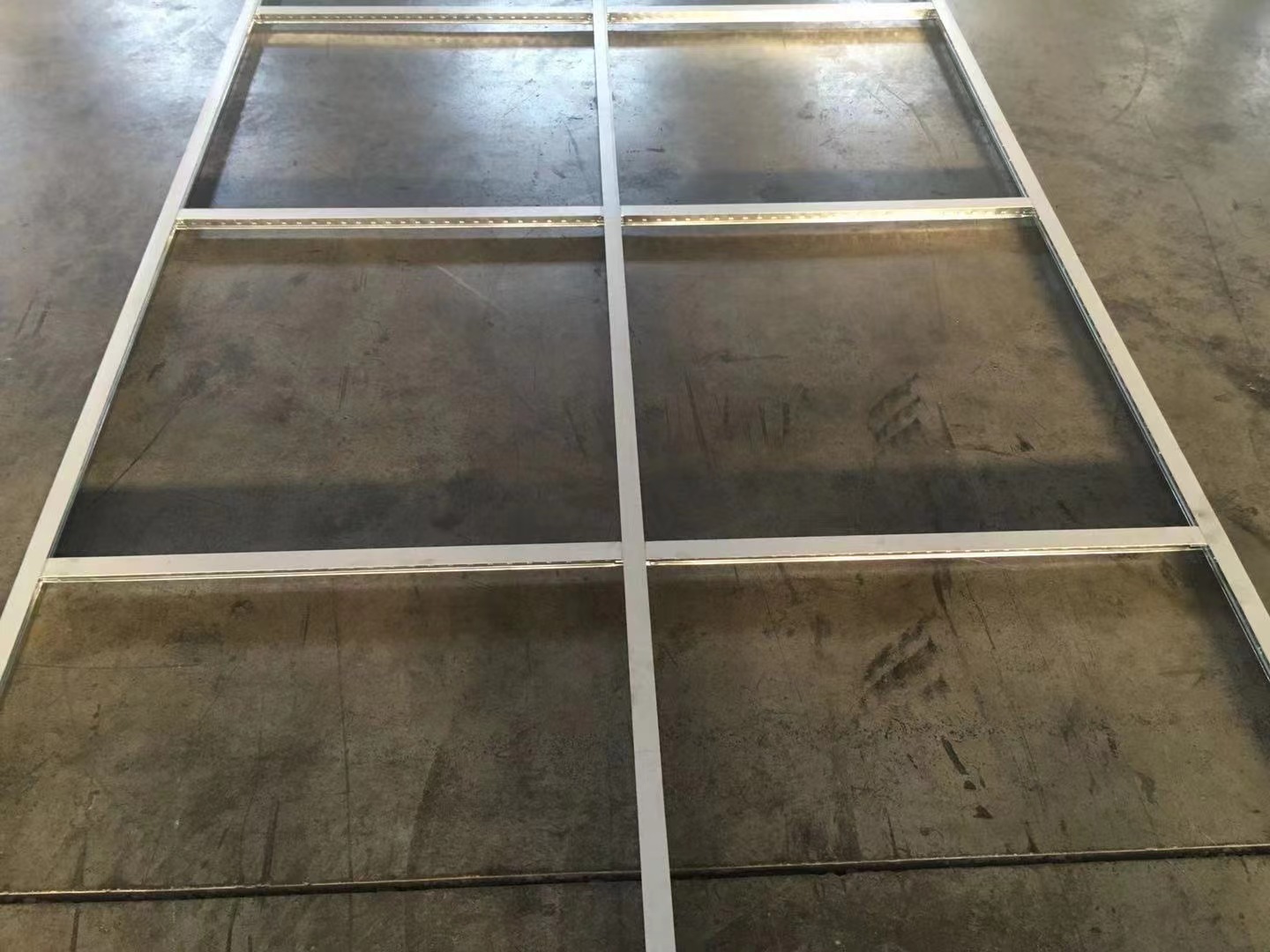

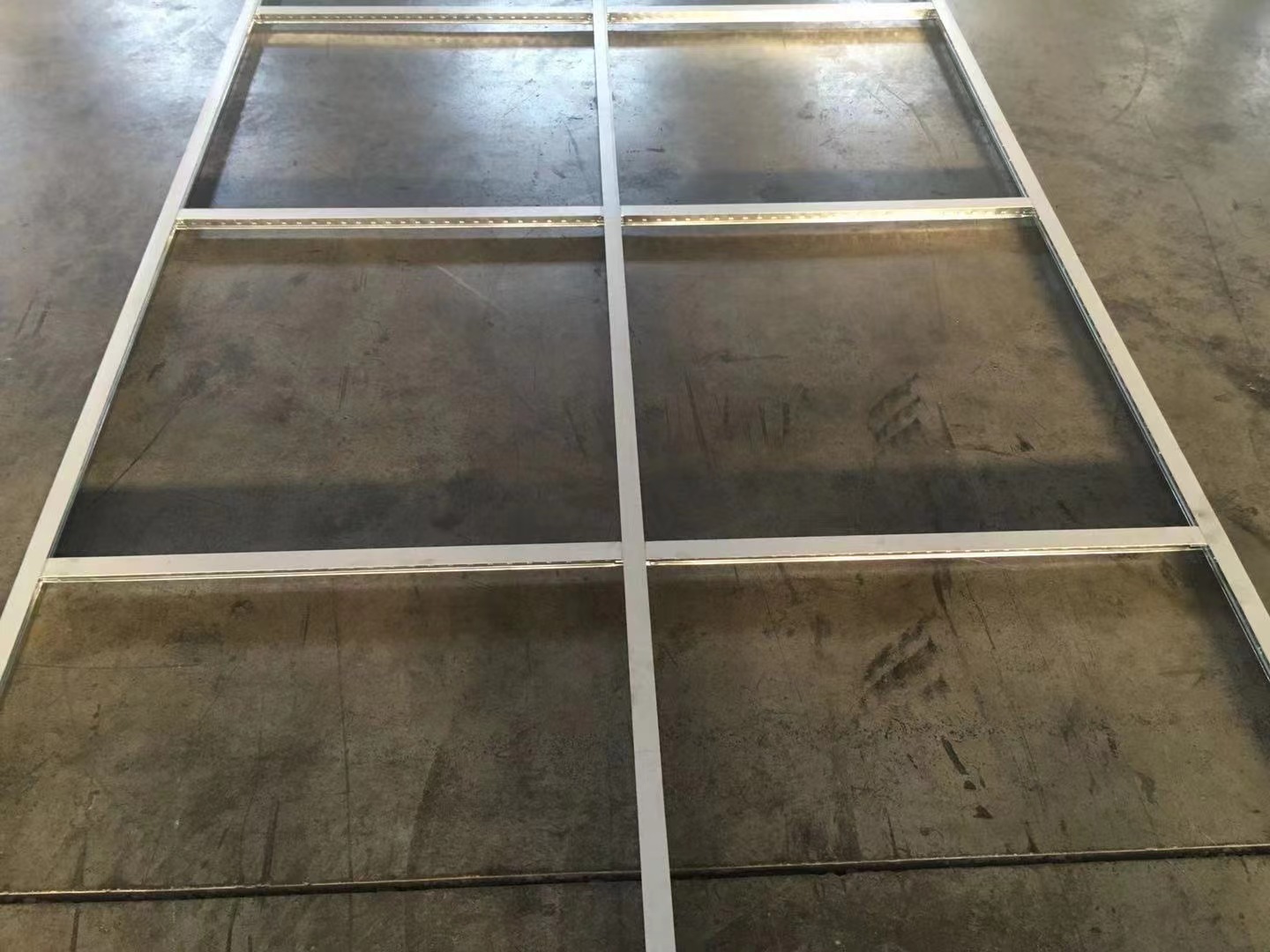

downpipe machine

Establishing authority in the downpipe machine industry requires a commitment to quality and innovation. Leading manufacturers invest heavily in research and development to stay at the forefront of technological advancements. Their products often undergo extensive testing and quality checks to meet international standards, giving users confidence in their reliability and finish. Moreover, brands that have maintained a longstanding presence in the industry naturally carry more weight, as they have demonstrated an ability to adapt and evolve with changing market demands.

Trustworthiness among consumers and industry professionals is paramount, especially when investing in machinery that is critical to construction projects. Reputable manufacturers offer comprehensive warranties and after-sales support, highlighting their commitment to customer satisfaction.

They also provide training and resources to ensure that operators can maximize the capabilities of their machines safely and efficiently. Trust is further cemented through transparent communication about the machine's capacities and limitations, allowing users to make informed decisions based on their specific requirements.

To summarize, downpipe machines have become an indispensable tool in the construction industry due to their enhanced efficiency, precision, and adaptability. The ongoing advancements in this field reflect a comprehensive approach that balances user experience, expert engineering, authoritative standing, and trustworthy practices. As buildings continue to evolve in complexity and design, the role of cutting-edge downpipe machines becomes even more critical, providing reliable solutions to water management challenges. By embracing innovation and maintaining a high standard of quality, manufacturers ensure that their machines remain an integral part of the construction landscape, trusted by builders across the globe.