The Double Layer Roof Sheet Forming Machine An Overview

In the construction and manufacturing industries, efficient and cost-effective production methods are paramount. One such innovation that has significantly transformed metal roofing production is the double layer roof sheet forming machine. This versatile piece of equipment allows manufacturers to produce two styles of roofing sheets simultaneously, maximizing efficiency and minimizing material waste.

Key Features and Functionality

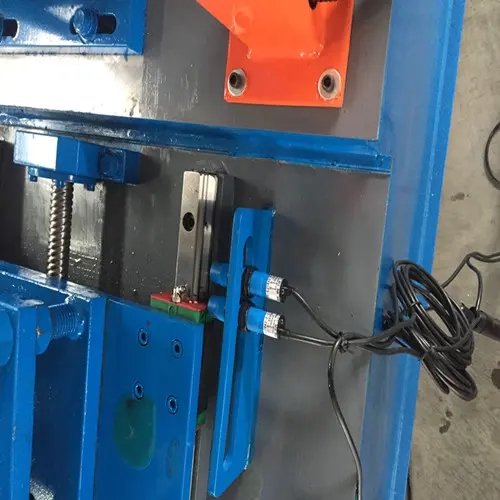

The double layer roof sheet forming machine is designed to handle two different profiles of roofing sheets, which can include traditional corrugated panels and modern flat sheets. This dual functionality is achieved through a sophisticated design that incorporates multiple rollers and adjustable configurations, enabling seamless switching between different sheet profiles. The production process involves feeding raw metal sheets into the machine, where they are shaped and cut to the desired specifications.

One of the most notable features of the machine is its robust construction, which is essential for withstanding the rigors of continuous operation. The rollers are typically made from high-quality steel that is hardened to ensure long-lasting performance and precision in shaping. Additionally, the machine often includes automated controls that allow for easy adjustments and monitoring of production parameters, ensuring consistency in sheet quality.

Benefits of the Double Layer Machine

1. Cost Efficiency By producing two types of sheets in one run, manufacturers can reduce labor costs and energy consumption. Instead of operating separate machines for each roofing style, a single double layer roof sheet forming machine suffices, allowing for streamlined operations.

2. Space Saving In manufacturing facilities where floor space is at a premium, the double layer machine is an attractive solution. It occupies a smaller footprint compared to multiple machines, enabling manufacturers to optimize their production lines without compromising output.

3. Versatility The ability to switch between different profiles makes this machine ideal for manufacturers catering to diverse customer needs. Whether the demand is for residential roofing, commercial applications, or custom projects, the double layer machine can adapt accordingly.

4. Enhanced Production Speed With advanced technology, these machines can produce roofing sheets at a rapid pace. This increased throughput not only meets demand but can also drive down unit costs, providing a competitive advantage in the market.

Applications

The double layer roof sheet forming machine is widely used in the construction sector, particularly for residential and commercial buildings. It is also beneficial for producing roofing solutions for industrial applications, agricultural buildings, and warehousing. Additional applications may extend to the manufacturing of wall panels, thus broadening the scope of its usability.

Conclusion

The introduction of the double layer roof sheet forming machine marks a significant advancement in the roofing material production sector. With its ability to produce multiple profiles efficiently and its inherent versatility, this machine represents an ideal solution for manufacturers looking to enhance their operational efficiency and responsiveness to market demands. As the construction industry evolves, such innovations will undoubtedly play a critical role in shaping the future of building materials production. Investing in a double layer roof sheet forming machine could very well be a strategic move for businesses aiming to thrive in a competitive landscape.