Double Layer Roof Sheet Forming Machine An Overview

The double layer roof sheet forming machine has revolutionized the way roofing solutions are manufactured in the construction industry. This advanced machinery is engineered to produce two distinct profiles of roof sheets simultaneously, enhancing efficiency and reducing production costs for manufacturers.

One of the primary advantages of the double layer roof sheet forming machine is its ability to save space and increase productivity. Traditional manufacturing setups often require separate machines for different roof sheet designs, occupying significant floor space and increasing operational complexity. In contrast, the double layer machine integrates two forming processes into a single unit, allowing manufacturers to diversify their product offerings without the need for additional equipment.

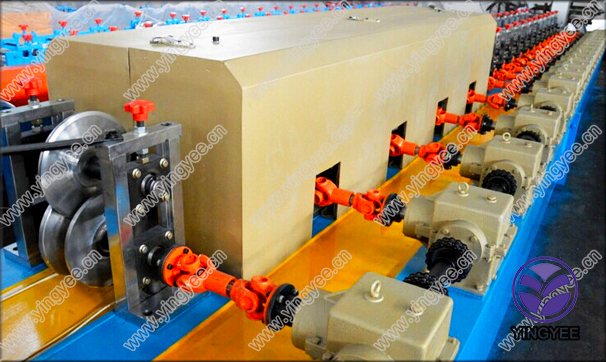

The machine operates using a sophisticated roll forming process, where steel coils are fed through a series of rollers that shape the material into desired profiles. This process ensures precision and consistency in the finished product, resulting in high-quality roof sheets that meet industry standards. Additionally, the versatility of the machine enables producers to customize sheet widths, thicknesses, and finishes according to client specifications, making it a flexible solution for construction projects of all types and scales.

Another notable benefit of the double layer roof sheet forming machine is its high production efficiency. With its advanced technology, the machine can produce impressive quantities of roof sheets in a short time, significantly reducing lead times and increasing output. This is particularly advantageous for manufacturers looking to fulfill large orders or respond quickly to market demands.

In terms of materials, the machine can accommodate a variety of substrates including galvanized steel, aluminum, and stainless steel, all of which can be further treated for enhanced durability and aesthetic appeal. This capability allows manufacturers to cater to different customer preferences and market trends.

Moreover, the double layer roof sheet forming machine is equipped with automated controls, which streamline the operation, reduce labor costs, and minimize the risk of human error. Operators can monitor the production process in real-time and make adjustments as necessary, ensuring optimal performance and product quality.

In conclusion, the double layer roof sheet forming machine represents a significant advancement in roofing material production. By offering space-saving design, high efficiency, product versatility, and automated controls, this machine not only meets the needs of manufacturers but also contributes to the broader goals of sustainability and cost-effectiveness in construction. As the demand for innovative roofing solutions continues to rise, the double layer roof sheet forming machine will undoubtedly become an essential asset in the industry.