The Double Layer Roof Sheet Forming Machine Revolutionizing Construction

In the modern construction industry, the need for efficient and high-quality building materials is paramount. Among various innovations, the double layer roof sheet forming machine has emerged as a game-changer, streamlining the production of roof sheets and significantly enhancing the overall building process.

What is a Double Layer Roof Sheet Forming Machine?

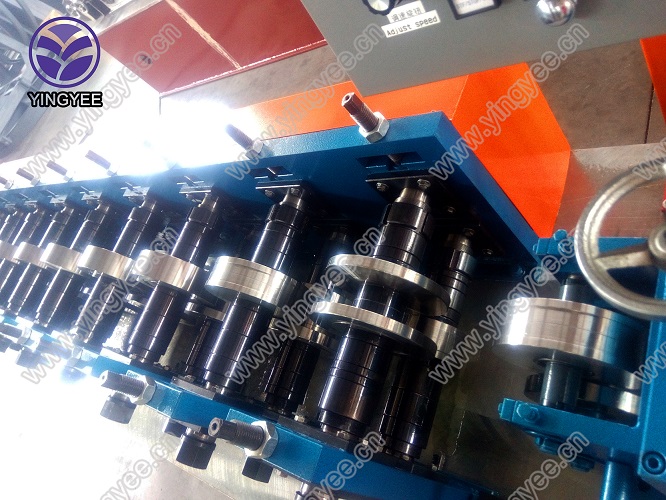

A double layer roof sheet forming machine is a sophisticated piece of equipment designed to create two types of roof sheets simultaneously. This machine utilizes roll forming technology, which involves passing metal coils through a series of rollers that gradually shape the metal into the desired profile. The resultant sheets are both sturdy and versatile, making them ideal for various applications, including residential, commercial, and industrial roofing.

Benefits of Using Double Layer Roof Sheets

1. Cost-Effectiveness One of the primary advantages of the double layer roof sheet forming machine is its ability to produce two different profiles from a single roll forming process. This not only saves on raw material costs but also reduces labor expenses, as fewer machines and operators are needed.

2. Space Efficiency Construction sites are often limited in space, making it crucial to optimize every square meter. By producing double-layer sheets, the need for storing multiple types of sheets is significantly reduced, offering greater flexibility and organization on-site.

3. Time Savings The simultaneous formation of two roof sheet profiles not only expedites the production process but also shortens lead times. This can be particularly beneficial for contractors and builders who are working under tight schedules.

4. Quality and Durability The double layer forming process results in sheets that are not only visually appealing but also possess enhanced strength and durability. They are designed to withstand various weather conditions, making them a reliable choice for building projects.

Applications in Modern Construction

Double layer roof sheets are widely used in various sectors, including residential homes, commercial buildings, warehouses, and industrial facilities. They offer excellent insulation properties, energy efficiency, and aesthetics, catering to diverse architectural styles and climates. As sustainability becomes increasingly important, many manufacturers are also producing these sheets from recycled materials, further enhancing their appeal.

Conclusion

The introduction of the double layer roof sheet forming machine has transformed the landscape of construction and roofing. By maximizing efficiency, reducing costs, and maintaining high standards of quality, this technology addresses the growing demands of the current building environment. As the industry continues to evolve, the role of innovative machinery like this will be crucial in shaping the future of construction, driving forward new possibilities for builders and homeowners alike. Embracing such advancements is essential for those looking to stay competitive in today’s fast-paced market.