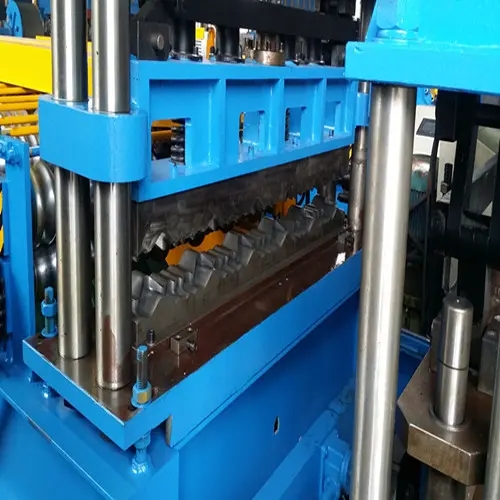

Door Frame Forming Machine Revolutionizing Door Frame Production

In the realm of construction and manufacturing, efficiency and precision are paramount. As the demand for high-quality door frames continues to rise, the need for advanced machinery to streamline production has become increasingly evident. Enter the door frame forming machine, a cutting-edge piece of equipment designed to revolutionize the way door frames are produced.

A door frame forming machine is specifically engineered to create door frames from various materials such as steel, aluminum, or PVC. The machine automates the forming process, significantly reducing labor costs and production time. Traditional methods of door frame production often involve manual labor, which can lead to inconsistencies in size, shape, and quality. In contrast, a door frame forming machine ensures uniformity and precision, producing door frames that meet the exact specifications required.

One of the standout features of modern door frame forming machines is their versatility. These machines can be adjusted to produce different styles and sizes of door frames to accommodate various architectural designs. Whether it’s a simple rectangular frame or a more complex design with intricate details, the forming machine can be calibrated to achieve the desired result. This flexibility not only enhances productivity but also allows manufacturers to respond swiftly to changing market demands.

Moreover, the integration of advanced technologies such as Computer Numerical Control (CNC) in door frame forming machines has further improved their performance. CNC technology allows for precise control of the machine’s movements, leading to high levels of accuracy in the production process. Operators can input specific measurements and design plans directly into the machine, minimizing the chances of human error and ensuring that each frame produced meets quality standards.

In addition to precision and versatility, door frame forming machines are designed with efficiency in mind. These machines can operate at high speeds, significantly increasing production rates. This capability is critical in today's fast-paced construction environments where time is of the essence. Manufacturers can produce large quantities of door frames in a shorter timeframe, allowing them to meet project deadlines and improve overall profitability.

Environmental considerations also play a role in the importance of door frame forming machines. Many of today’s machines are designed to minimize waste and utilize eco-friendly materials, aligning with the growing trend toward sustainable building practices. By optimizing the use of raw materials and reducing offcuts, manufacturers can not only lower their costs but also contribute positively to environmental conservation efforts.

In conclusion, the door frame forming machine represents a significant advancement in the manufacturing of door frames. With its ability to produce high-quality, precise frames quickly and efficiently, it has transformed the industry. As technology continues to evolve, we can expect even more innovations in door frame production, further enhancing the capabilities of these machines and setting new standards for quality and efficiency in construction. Investing in a door frame forming machine is not just about keeping up with the competition; it is about pioneering a future where manufacturing processes are smarter, faster, and more sustainable.