The Door Frame Roll Forming Line An Innovative Solution for Modern Construction

In the world of construction and manufacturing, efficiency, durability, and precision are paramount. The door frame roll forming line has emerged as an innovative solution that addresses these needs by streamlining the production process for door frames. This state-of-the-art technology not only enhances factory productivity but also ensures high-quality output that meets the modern demands of the construction industry.

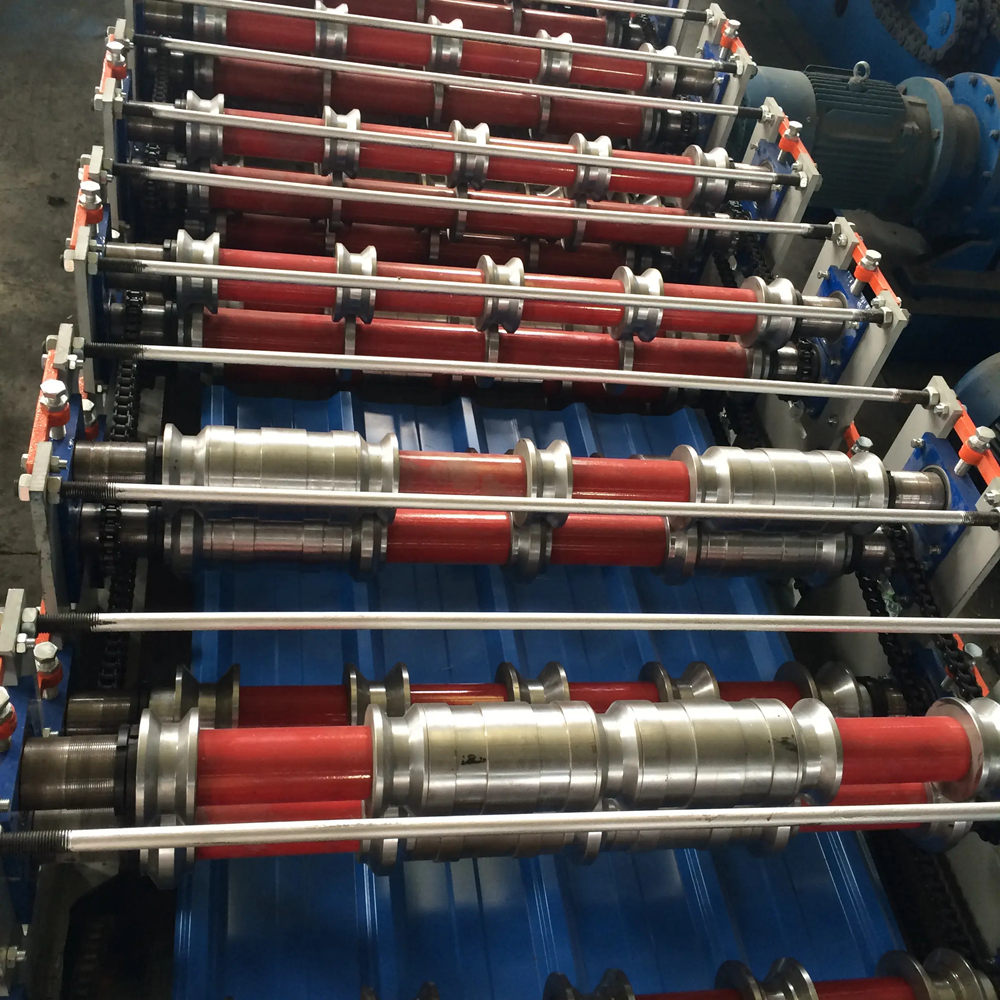

A door frame roll forming line is a specialized manufacturing system designed for creating door frames from metal, typically steel or aluminum. This system operates by continuously feeding a coil of metal through a series of rollers, which shape the material into a pre-defined profile. The process involves several stages, including feeding, forming, cutting, and finishing, each engineered to achieve optimal results. The ability to produce customized door frames in various styles and sizes makes this technology particularly appealing in a market that values versatility.

One of the significant advantages of a door frame roll forming line is its efficiency. Traditional methods of manufacturing door frames often involve labor-intensive processes, resulting in longer production times and higher costs. In contrast, roll forming is a continuous operation that requires minimal manual intervention. This not only speeds up the production cycle but also reduces the likelihood of errors, leading to lower waste and better resource management.

The precision offered by roll forming technology is another key benefit. Each roll forming line is designed with accuracy in mind, ensuring that every frame produced adheres to strict specifications. This level of precision is especially important in construction, where proper fitting of door frames is crucial for functionality and aesthetic appeal. Furthermore, the consistent quality of the output means that construction projects can proceed on schedule, with fewer delays due to frame defects.

Durability is a critical factor in choosing materials for construction, and the door frame roll forming line excels in this aspect. Metal door frames produced through this process are robust and resistant to various environmental factors, including moisture, temperature fluctuations, and physical impacts. This durability translates into longer lifespans for the door frames, reducing the need for repairs and replacements over time. Given the increasing focus on sustainability in construction, the longevity of these frames can significantly contribute to reducing environmental impact.

Moreover, advances in technology have allowed for greater integration of automation within roll forming lines. Automated systems enhance precision and speed while minimizing labor costs. Features such as computerized controls and real-time monitoring further optimize the production process, allowing manufacturers to respond swiftly to market demands.

As the construction industry continues to evolve, the importance of efficiency, durability, and precision will remain central to its growth. The door frame roll forming line represents a significant step forward in achieving these objectives, providing manufacturers with a competitive edge in a demanding market. By embracing this innovative technology, companies can not only improve their operational outputs but also contribute to shaping the future of construction.

In conclusion, the door frame roll forming line is more than just a manufacturing tool; it is a transformative solution that meets the evolving needs of the construction industry. With its promise of efficiency, quality, and durability, it stands as a testament to how technology can enhance traditional practices and drive the sector forward. As companies increasingly seek ways to innovate, the adoption of such advanced production methods will likely become the norm, paving the way for a new era in construction.