The Role of Decking Floor Roll Forming Machines in Modern Construction

In the ever-evolving world of construction, efficiency and precision are key to delivering high-quality structures while minimizing costs and delays. One of the most innovative tools contributing to this goal is the decking floor roll forming machine. This equipment plays a critical role in the production of deck panels used for flooring systems in commercial and residential buildings alike.

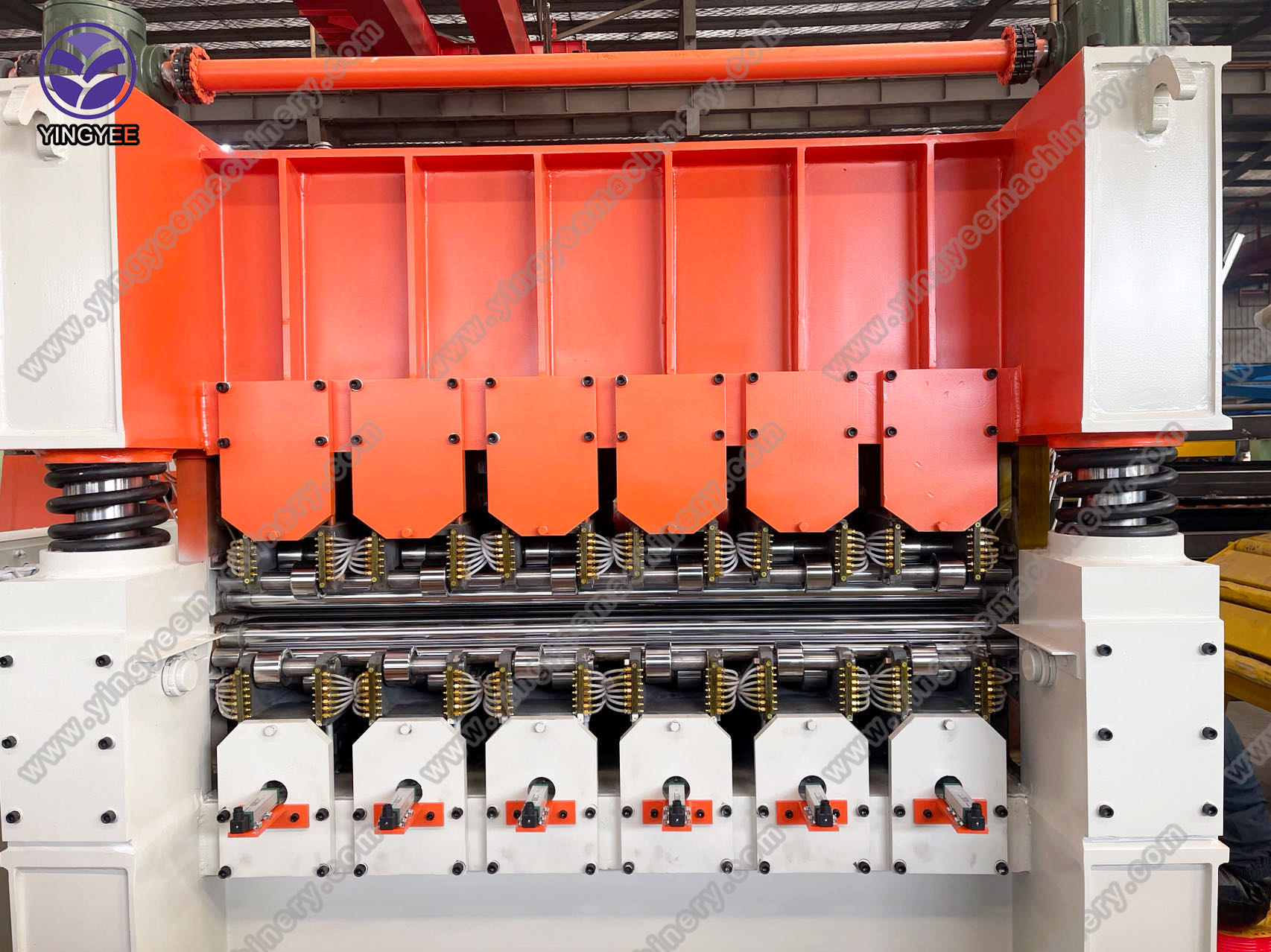

Understanding Decking Floor Roll Forming Machines

Decking floor roll forming machines are specialized equipment designed to manufacture metal decking sheets, often made from steel or aluminum. The process involves feeding a flat metal sheet through a series of rollers that shape the material into specified profiles. These profiles feature ribs or grooves that provide additional strength and facilitate the construction process by creating a surface that can easily be attached to supporting beams or joists.

These machines can handle a variety of gauges and widths of material, allowing manufacturers to produce a diverse array of decking products. Typically, the end products are lightweight yet strong panels that can support heavy loads, making them ideal for use in floors, roofs, and even walls.

Advantages of Using Roll Forming Machines

1. Cost Efficiency One of the most significant benefits of roll forming machines is their ability to produce decking panels at a lower cost compared to traditional methods. The automated process reduces labor costs and minimizes waste, which can lead to significant savings for construction companies.

2. Consistency and Quality Roll forming machines ensure that every panel produced is uniform in size and shape. This consistency is crucial for structural integrity and reduces the likelihood of errors during installation, ultimately enhancing the overall quality of the construction project.

3. Speed of Production The automated nature of roll forming allows for rapid production rates. A continuous operation can generate large quantities of decking material in a short period, ensuring that construction timelines are met without unnecessary delays.

4. Customizable Designs Many roll forming machines can be customized to create specific profiles tailored to unique project requirements. This flexibility enables architects and builders to design structures that meet aesthetic and functional needs without compromising on structural performance.

5. Durability and Strength Metal decking produced by roll forming is typically stronger than other materials, such as plywood or traditional wood decking. This strength translates into better load-bearing capabilities and longer lifespan, making it a preferred choice for many construction projects.

Applications in Construction

The applications of decking floor roll forming machines are vast and varied. These machines are commonly used in the construction of

- Commercial Buildings For shopping centers, office buildings, and warehouses, metal decking provides the necessary strength to support heavy floors and roofing systems.

- Industrial Facilities Factories and manufacturing plants utilize durable metal decks that can withstand the demands of heavy machinery and equipment.

- Residential Projects Increasingly, homeowners are opting for metal decking due to its durability and resistance to environmental factors, making it suitable for both roofs and floors.

- Infrastructure Projects Bridges and parking garages benefit from the strength and light weight of metal decking, allowing for innovative designs that can accommodate heavy traffic loads.

Conclusion

In summary, decking floor roll forming machines are an indispensable component in modern construction. Their ability to produce high-quality, customizable decking solutions at a lower cost and higher speed makes them vital for contractors looking to enhance efficiency without sacrificing quality. As the construction industry continues to innovate and strive for sustainability, the role of roll forming technology will undoubtedly grow, paving the way for stronger, safer, and more cost-effective building methods. Embracing these technologies not only streamlines construction processes but also contributes to the overall advancement of the industry.